Introduction: Your Procurement Challenges, Our Manufacturing Solutions

As a procurement manager for wholesale components, your primary challenges are clear: securing a supply chain that guarantees quality, meets tight cost targets, and delivers on time, every time.

Any deviation in part consistency can halt your assembly lines. Likewise, any unforeseen cost can erode your margins. At YISHANG, with over 26 years of OEM CNC machining experience and delivery to 50+ countries, we understand that our performance is directly tied to your success.

That is why we have built our operations around advanced CNC (Computer Numerical Control) automation. This article provides a transparent look into how our strategic investment in technology directly solves your procurement challenges. In doing so, we ensure we are structured to deliver consistent value beyond machining services. Whether you’re evaluating a new iso9001 cnc machining supplier or optimizing your bulk cnc parts sourcing in China, this guide is built for you.

Part 1: The Foundation of Trust — Mitigating Risk with Guaranteed Quality

For any wholesale buyer, the number one concern is risk mitigation. You need absolute assurance that every component in every batch meets specifications. Fortunately, our quality systems and technology are engineered to provide that certainty.

From the First to the Ten-Thousandth: Perfect Replication for Supply Chain Stability

In high-volume production, consistency is paramount. A single out-of-spec part can cause costly delays. Consequently, our commitment to perfect replication is built on the exceptional CNC repeatability of our automated systems.

Unlike manual processes, which are prone to human error and fatigue, our CNC controlled machines execute a validated digital program with flawless consistency. As a result, every cnc machined part is dimensionally identical, from the first unit to the last.

This level of precision is essential for cnc close tolerance machining, especially in custom CNC parts for automotive or medical industries. Therefore, you can trust our components to integrate seamlessly into your assembly processes, reducing your downstream quality control burden and ensuring a stable, predictable supply chain.

🔎 Why this matters: It minimizes rework costs and ensures predictable, scalable delivery.

Delving into Micron-Level Precision: The Engineering Behind Our Accuracy

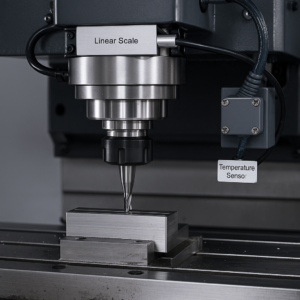

Claiming we produce accurate cnc parts is one thing; showing how we do it builds true credibility. Our precision stems from a sophisticated, self-correcting technology embedded in our machines: the closed-loop feedback system.

Our machine axes rely on high-efficiency ball screws. Over long production runs, however, the work performed generates heat, which causes thermal expansion of metal components. Understandably, this can introduce microscopic dimensional drift.

To counteract this, we equip our machines with linear encoders—independent measurement systems that constantly report the tool’s true position. When deviations of just a few microns occur, the controller reacts immediately with micro-adjustments. This system lies at the heart of cnc precision machining and reinforces our standing as an iso-certified cnc machining partner.

🔎 Why this matters: Precision ensures component fit, function, and reliability in your final assemblies.

Part 2: The Economics of Efficiency — Driving Down Your Cost-Per-Part

Your goal is to secure the best possible price without compromising quality. At YISHANG, our efficiency-focused model is designed to deliver exactly that. We lower your cost-per-part by relentlessly optimizing our technology and workflows.

The Direct Conversion of Speed to Cost: How Faster Cycle Times Benefit You

In manufacturing, time directly drives cost. One significant benefit of cnc machining is speed. We harness advanced CAM software to generate optimized toolpaths, employing techniques like High-Efficiency Milling (HEM) to remove material faster and smarter.

Moreover, we utilize Automatic Tool Changers (ATCs) that reduce tool-switching delays. As a result, we achieve drastic reductions in total cycle time for each part.

This high throughput allows us to produce more parts in less time, reducing overhead and labor costs. These savings are passed directly to you—especially valuable when managing OEM bulk CNC machining projects.

🔎 Why this matters: Reduced cycle time = lower unit cost = higher profit margin for you.

“Lights-Out” Manufacturing: Our 24/7 Capability for Your High-Volume Needs

To further increase efficiency, YISHANG utilizes the principles of lights-out manufacturing. Through robotic automation, we operate our machines 24/7 with minimal human supervision.

Typically, traditional machines only achieve 25–30% utilization during daytime shifts. In contrast, our automated cells consistently exceed 90% utilization. This leap in productive capacity dramatically shifts the cnc machining cost structure in your favor.

This efficiency allows us to spread equipment and facility costs over significantly larger volumes. Ultimately, that means we can support your high-volume, time-sensitive orders at competitive prices. For procurement managers exploring a custom cnc aluminum parts supplier, our approach ensures not only tight tolerances but also fast, scalable output.

🔎 Why this matters: Enables consistent delivery for blanket PO agreements and large volume production.

Part 3: From Concept to Component — Your Most Complex Designs, Made Real

Your engineers are constantly innovating. As a result, you need a cnc machined parts manufacturer who can handle that complexity without compromise.

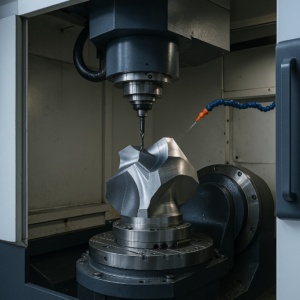

Breaking Through 3D Limitations: Our 5-Axis CNC Machining Capabilities

Many modern components, such as cnc machined automotive components, feature curves and angles that can’t be achieved on a standard 3-axis machine in one setup.

That’s why we invested in 5-axis CNC machining. By adding two rotational axes, a cnc 5 axis mill approaches parts from virtually any angle. This enables us to create complex geometries in a single operation.

Not only that, but the “done-in-one” method also improves accuracy by eliminating cumulative error from multiple setups. For less complex jobs, our 4-axis CNC machining centers provide efficient and precise results.

While cnc turning vs cnc milling each offer unique advantages, 5-axis milling stands out when it comes to multi-surface, tight-tolerance work.

🔎 Why this matters: Complex components are made with fewer setups, less tooling, and lower cumulative error.

The Seamless Digital Workflow: From Your CAD File to Our Shop Floor

From your CAD file to the finished part, the process should be seamless. Our integrated CAD/CAM workflow creates a continuous digital thread that eliminates manual errors.

We import more than 50 cnc file format types, including STEP, IGES, and DXF. Then, our engineers develop precision toolpaths in CAM, followed by a full simulation before production begins.

Because we resolve issues in the digital stage, we eliminate costly trial-and-error on the floor. This is particularly valuable for cnc rapid prototyping and short-run production.

🔎 Why this matters: Shorter lead times, higher accuracy, and lower prototyping cost.

Part 4: Material Expertise — Strategic Guidance for Your Application

As a trusted CNC machining China factory, we don’t just cut metal—we guide your sourcing decisions. Our engineers help you match materials to application goals, budget, and performance.

More Than a Choice, It’s a Strategy: Balancing Performance and Cost

Material selection impacts cost and manufacturability. For example, Titanium is incredibly strong but difficult to machine, whereas aluminum for cnc offers a cost-effective, high-performance alternative.

We help you weigh trade-offs, considering corrosion resistance, strength, conductivity, and surface finish. This prevents both over- and under-engineering, so you can maximize ROI.

🔎 Why this matters: Smart material choices save time, reduce waste, and improve price-performance.

Quick Reference Guide to Core Metal Materials

| MaterialKey CharacteristicsMachinability RatingCost IndexYISHANG’s Recommended Application Scenarios | ||||

|---|---|---|---|---|

| Aluminum 6061 | Excellent strength-to-weight, versatile, cost-effective, highly machinable. | ★★★★★ | $$ | The go-to alloy for structural components, electronic enclosures, and general-purpose parts. |

| Aluminum 7075 | Very high strength, comparable to steel but lighter. Harder to machine. | ★★★★ | $$$ | High-stress, weight-sensitive applications such as aerospace and high-performance automotive parts. |

| Stainless Steel 304 | Excellent corrosion resistance, good strength. More challenging to machine. | ★★ | $$$ | Food-grade equipment, medical devices, architectural fixtures, and general corrosion-resistant parts. |

| Stainless Steel 316 | Superior “marine-grade” corrosion resistance, especially against chlorides. | ★★ | $$$$ | Marine hardware, chemical processing equipment, and medical implants in corrosive environments. |

| Mild / Carbon Steel | High strength, durable, and highly cost-effective. Requires coating to prevent rust. | ★★★ | $ | Ideal for structural frames, machinery components, and fixtures where strength is key and cost is a primary driver. |

| Brass (C360) | Extremely high machinability, good corrosion resistance, electrically conductive. | ★★★★★ | $$ | Best for plumbing fittings, electrical connectors, and decorative hardware requiring a fine finish. |

Part 5: Your Future-Ready Partner — Our Commitment to Innovation

Selecting a vendor is no longer just about price. Today, you need a partner that evolves with technology. YISHANG invests in future-ready manufacturing to keep your supply chain competitive.

Intelligent Manufacturing: How AI Makes Our Production More Reliable

We’ve implemented AI in CNC operations. Our systems analyze real-time sensor data to detect maintenance issues before they happen.

Through predictive maintenance, we reduce downtime, enhance uptime, and ensure your orders ship on schedule. This level of operational intelligence is essential for modern supply chains.

🔎 Why this matters: Maximized uptime equals better OTD (On-Time Delivery) for your supply chain.

Responsible Manufacturing: Our Commitment to Sustainability

We’ve also committed to green machining. Our energy-efficient equipment reduces power consumption, and we recycle 100% of metal waste.

As procurement increasingly incorporates ESG goals, working with a sustainable partner matters. Our process helps you align with environmental standards without increasing costs.

🔎 Why this matters: Helps you meet ESG targets and supports your green procurement goals.

Frequently Asked Questions (FAQ)

Q1: Do you accept both small and large volume CNC orders?

Yes. We support low-volume prototyping and high-volume production alike. If you’re looking for bulk cnc parts sourcing in China, we have the scale and logistics infrastructure to meet demand.

Q2: Can you work with overseas CAD file formats and tolerance systems?

Absolutely. We support STEP, IGES, DXF, and SolidWorks files. Our shop handles both metric and imperial units and conforms to ISO, DIN, and ANSI tolerances.

Q3: What industries do you primarily serve?

We serve OEMs in automotive, electronics, vending, consumer hardware, agriculture, medical device frames, and more.

Q4: What certifications do you hold?

We are ISO 9001 certified and comply with RoHS. Documentation is available upon request.

Conclusion: Your Partner for Manufacturing Excellence

YISHANG invests in advanced CNC automation, intelligent systems, and deep material expertise to deliver consistent value to wholesale buyers.

We’ve successfully delivered OEM CNC parts to over 50 countries. If you’re ready to streamline your sourcing process with a reliable manufacturing partner, send us your design files for a fast, competitive quote.