Introduction: When Precision Is Mission-Critical

In drone manufacturing, component reliability is not a luxury—it’s mission-critical. For bulk procurement professionals, choosing CNC-machined drone parts isn’t just about engineering precision. It’s about ensuring long-term operational stability, streamlined assembly, and guaranteed compliance in high-demand environments.

This article provides a deep dive into how CNC-manufactured drone parts impact manufacturing quality, procurement efficiency, and field performance. Designed specifically for overseas B2B buyers, it highlights the data, terminology, and standards that matter when sourcing large quantities of UAV components.

Why CNC Machining Is the Backbone of Industrial Drone Component Production

Delivering Repeatable Accuracy at Scale

Industrial UAVs used in mapping, logistics, and surveillance operate under tight tolerance requirements. CNC machining provides micron-level precision and ensures that every batch of drone components meets the same specification, a necessity for large production runs.

For buyers dealing with batch sizes of thousands, this level of consistency reduces assembly rejection rates and enhances compatibility across multiple models. CNC enables drone manufacturers to rely on lot-to-lot dimensional repeatability within ±0.01 mm.

Reducing Field Failure Risks

Unmanned vehicles face wind load, vibrations, and extended operation cycles. Poorly machined components introduce imbalance or stress concentration, which can lead to flight instability or structural failure. CNC drone parts mitigate these risks through advanced geometrical control and optimized material usage.

Key CNC Drone Parts: Functions and Fabrication Considerations

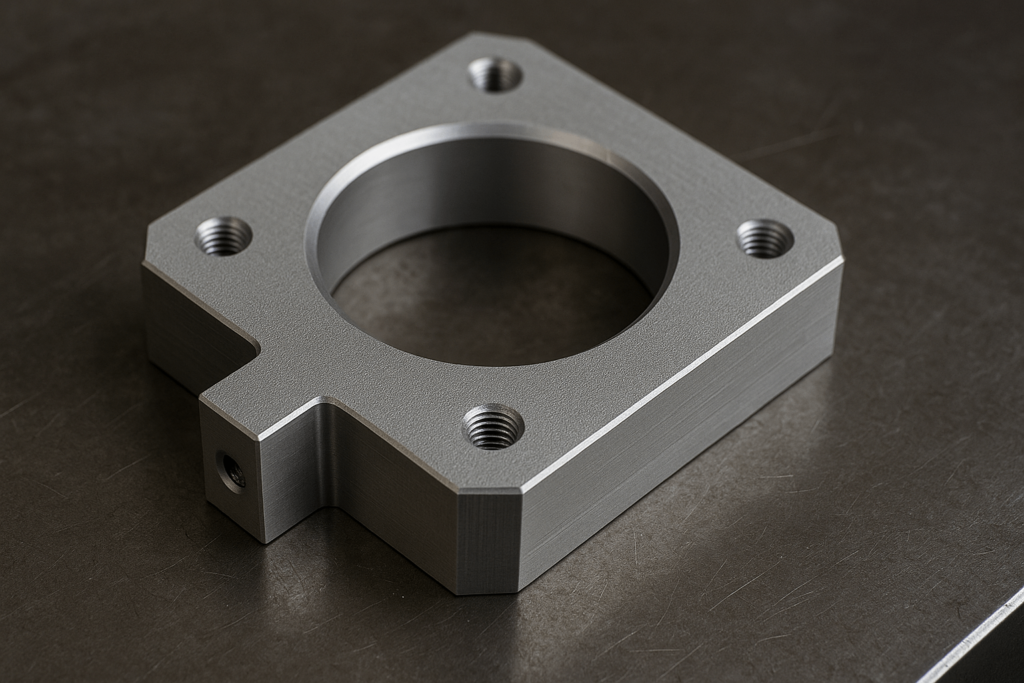

Structural Frames and Mounting Brackets

These core load-bearing elements must withstand torsional forces and high-frequency vibration. Materials like 6061-T6 and 7075-T6 aluminum are common, with CNC ensuring weight-saving cutouts without compromising strength.

Customizing bracket hole patterns and curvature via CNC allows buyers to match mounting interfaces with different payload modules or battery housings. This reduces the need for secondary fitting operations.

Gimbal Arms, Motor Mounts, and Propeller Hubs

These parts require dynamic balance and rotational symmetry. CNC-controlled turning and milling allow precise concentricity control for vibration-sensitive drone sections.

Buyers benefit from parts that are ready-to-install, minimizing manual adjustment on production lines and ensuring motor alignment in large-scale UAV production.

Enclosures for Electronics and Sensors

Thermal management is crucial. CNC-cut aluminum housings provide both structural protection and passive cooling. Custom ventilation geometry or anodized coatings can be specified in the procurement phase.

When selecting NEMA or IP-rated enclosures, sourcing from a CNC metal manufacturer like YISHANG ensures dimensional compatibility with PCBs and internal wiring harnesses.

Choosing the Right Materials: From Aluminum to Stainless Steel

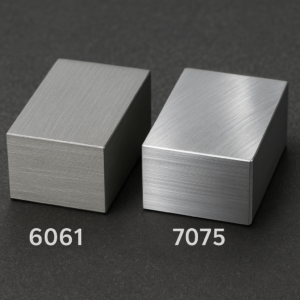

Aluminum Grades: Strength-to-Weight Tradeoffs

| Grade | Use Case Example | Key Properties |

|---|---|---|

| 6061-T6 | Mid-size drone frames | Corrosion resistance, easy machining |

| 7075-T6 | Propeller arms, gimbals | High tensile strength, fatigue resistance |

Buyers should specify material certifications and surface treatment (e.g., Type II or Type III anodizing) to prevent oxidation in humid environments.

Stainless Steel and Carbon Steel

Used less frequently due to weight, but ideal for parts like hinges, locking mechanisms, or battery tray fasteners, where corrosion and impact resistance outweigh lightweight needs.

YISHANG supports RoHS-compliant, ISO9001-certified metal sourcing, helping overseas buyers meet their own downstream compliance requirements.

Engineering Design for Procurement Efficiency

Built-in Assembly Logic

Good drone part design is not just strong—it’s assembly-optimized. CNC allows tapped holes, interlocking slots, and chamfers that reduce human error and save production time.

If a part consistently adds 5 seconds of alignment time per unit, this cost compounds over 10,000 drones. That’s why CNC suppliers like YISHANG pre-machine locating features and pilot holes into every component.

Minimized Post-Machining Operations

Well-designed CNC drone parts remove the need for deburring, secondary welding, or manual grinding. For procurement teams, this reduces cost-per-part and labor hours downstream.

Requesting CAD-to-G-code simulation during quotation can help procurement teams forecast secondary costs more accurately.

Tolerance Control and Quality Assurance in Mass Production

The Role of Tight Tolerances in UAV Performance

For drone components like gimbal plates or motor arms, tolerances below 0.05 mm are standard. This ensures rotational stability and avoids vibration-induced sensor errors.

YISHANG provides First Article Inspection (FAI) and Statistical Process Control (SPC) reports for large-batch buyers—key documents for quality-sensitive industries like defense or geospatial survey.

Dimensional Verification and CMM Inspection

Procurement teams should ensure vendors have CMM (Coordinate Measuring Machine) capability and provide traceable inspection reports. These reports must match technical drawings with GD&T annotations.

Why Buyers Choose CNC Over Other Fabrication Methods

| Method | CNC Machining | Laser Cutting | Die Casting |

|---|---|---|---|

| Setup Time | Short (fast prototyping) | Medium | Long (mold design) |

| Batch Size | Ideal for low to mid volumes | Mid to large | Large volume only |

| Customization | High | Medium | Low |

| Surface Finish | Excellent (Ra < 1.6µm) | Fair | Variable |

CNC is favored by OEMs needing agile customization without the sunk costs of casting dies or long mold lead times. This is especially relevant when producing multiple drone variants or modular designs.

Packaging, Traceability, and Shipment Logistics

Packaging That Preserves Part Integrity

Bulk buyers should expect parts to be separated by foam or corrosion-inhibiting paper (VCI) and sealed in moisture-resistant bags. For enclosures, caps should be included to protect threads and ports.

YISHANG offers packaging customization for drone kits, allowing kitting by assembly sequence (e.g., frame kits, control box kits) to reduce warehouse sorting times.

Traceability and Certification Support

For industrial drone buyers, YISHANG can embed QR-encoded traceability labels on each batch, allowing integration into ERP or MRP systems.

Documentation such as material certification, IP rating proof, and ISO9001 compliance are also supplied for smooth customs clearance and audit readiness.

Real-World Case: Reducing Assembly Time by 23% with Pre-Fitted CNC Brackets

A European logistics UAV manufacturer sourced CNC motor brackets from YISHANG, replacing their previous sheet metal brackets.

By integrating pre-machined pilot holes, chamfers, and dowel pin slots, the client reduced alignment time by 8 seconds per bracket. Over 5,000 units, this translated to a 23% time saving on final assembly and a measurable drop in worker error rate.

This is one of many cases where design-for-assembly (DFA) principles, implemented via CNC machining, bring direct ROI to procurement teams.

What to Look for in a CNC Drone Parts Supplier

Procurement-Centric Qualities

- Batch-to-batch consistency backed by SPC

- Ability to scale from samples to full runs

- Fluent communication on drawings & tolerances

- Support for third-party audits and documentation

Questions Procurement Teams Should Ask

- Can the supplier meet required IP or NEMA ratings for enclosures?

- Are inspection reports tied to technical drawings?

- Do they offer support for surface finish certifications?

CNC Drone Parts Procurement FAQ

Q1: What’s the minimum order quantity (MOQ)?

A: YISHANG supports flexible MOQ from 50 pcs to 5000+ pcs depending on part complexity.

Q2: Can you handle anodizing or plating?

A: Yes. We support Type II/III anodizing, chromate conversion, and electroless nickel plating.

Q3: Do you support design iteration?

A: Absolutely. Our engineering team offers feedback based on machinability, thermal paths, and stress points.

Q4: How do you ensure batch quality consistency?

A: Through in-process inspections, final FAI, and available full CMM reporting.

Q5: What shipping terms do you support?

A: EXW, FOB, CIF, and DDP to over 50 countries with commercial invoice & HS codes attached.

Conclusion: CNC Drone Parts Built for Procurement Success

From raw material control to final packaging, CNC drone components play a decisive role in performance, assembly efficiency, and long-term ROI. For procurement teams, this isn’t just about buying parts—it’s about building a reliable supply chain.

At YISHANG, we specialize in high-precision drone component manufacturing that aligns with global buyers’ quality, compliance, and lead time needs.

Send your inquiry today, and let’s help you simplify your supply chain while scaling your UAV production with confidence.

📌 FAQ: Common Questions about CNC Drone Parts for Industrial Buyers

1. What are the most recommended materials for CNC drone parts in commercial UAVs?

Aluminum 6061 and 7075 are most commonly used for lightweight structural strength, while carbon fiber is favored for arms and frames requiring high stiffness-to-weight ratio. Stainless steel is ideal for payload mounting and critical fasteners requiring corrosion resistance.

2. Can I request customized tolerance levels or surface treatments for my drone parts?

Absolutely. YISHANG supports tolerance customization (down to ±0.01 mm for precision-critical components), and offers anodizing, powder coating, polishing, and passivation to meet aerospace or weatherproofing needs.

3. What’s your MOQ for CNC drone components, and do you offer samples?

The typical MOQ is 100 pcs per part type. However, prototype samples can be arranged with flexible pricing based on design complexity and volume potential.

4. Do your CNC parts comply with RoHS or aerospace material standards?

Yes. All parts are RoHS-compliant by default. We also support sourcing aerospace-grade aluminum (e.g., 7075-T6, 2024) or providing relevant raw material certifications such as SGS, TUV, or material inspection reports on request.

5. How do you ensure precision and consistency in bulk production?

Each production run follows a full QA protocol including CNC program verification, first-article inspection (FAI), random batch SPC sampling, and dimensional inspection using CMM and height gauges.

6. Can you assist with design optimization or DFMA for better cost control?

Yes. Our engineering team can review 2D drawings or 3D files (e.g., STEP, IGES) and provide design-for-manufacturing (DFM) feedback to minimize machining cost and reduce unnecessary tolerances or undercuts.

7. What is your standard lead time for mass orders of CNC drone parts?

For standard volume orders (1000–3000 pcs), lead time is typically 15–20 working days after final drawing confirmation and deposit. Urgent production is available upon request with added cost.