Introduction: The Manufacturing Decisions That Define Victory

In competitive motorsports, victory often depends on fractions of a second. While a last-lap overtake may seem like a moment of driver brilliance, its origin lies far from the racetrack.

Each race validates engineering and manufacturing decisions made months earlier. The real battle takes place in the machine shop. Here, engineers face constraints of physics, material science, and scalable production.

This guide helps engineering leaders and procurement professionals navigate those challenges. Rather than listing parts, we explore how Computer Numerical Control (CNC) machining provides the foundation for modern motorsports.

We’ll show how a solid metal billet becomes a high-performance component. You’ll see how precision manufacturing ensures quality, consistency, and supply chain reliability. For those seeking a custom CNC racing parts supplier or bulk CNC parts for vehicles, this guide outlines what to look for in a partner like YISHANG.

1. The Foundational Principle: How Manufacturing Precision Translates to Performance

Why Micron-Level Precision Matters

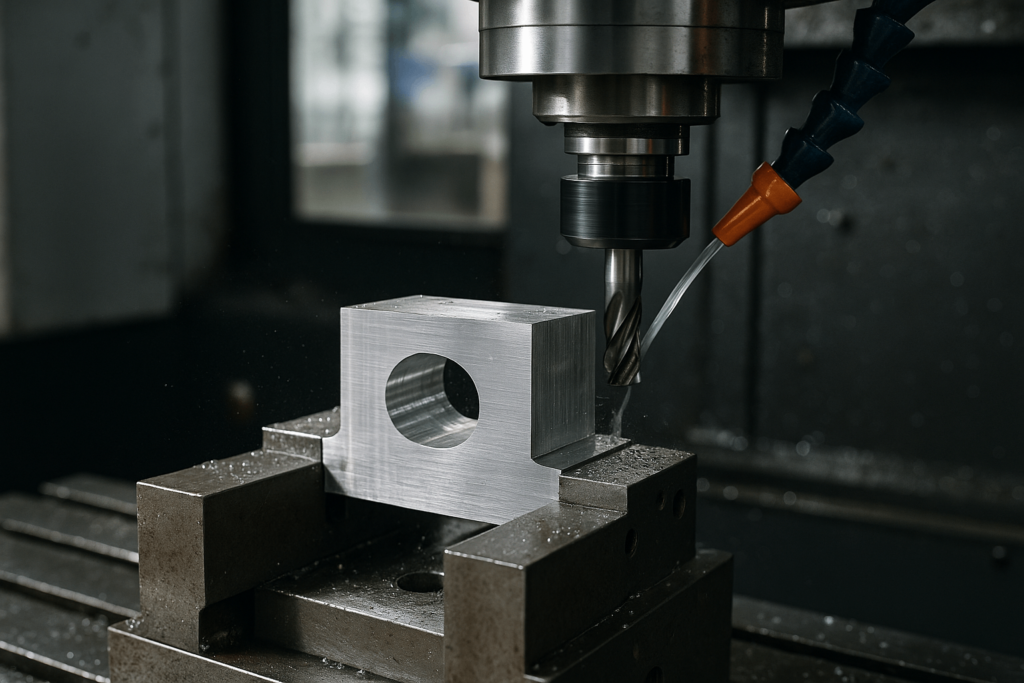

Precision manufacturing allows for exact component tolerances. CNC machines regularly hold tolerances as fine as ±0.0001 inches. That means moving parts fit together with minimal friction and zero play. The result? Smoother power transfer, faster acceleration, and reduced vibration.

Engineers achieve this accuracy by using subtractive machining. Tools carve away material from solid billets to form final parts. The method creates dense, uniform grain structures. These structures lack the porosity common in cast parts, resulting in stronger and more durable components.

Consistent Quality Across Production Runs

Precision doesn’t just benefit a single component. When every part matches the design spec across batches, teams reduce failure risks. CNC machining ensures repeatability, critical in motorsports where a single weak link could end a race.

To achieve that consistency, suppliers use multiple techniques:

- 5-axis CNC milling reaches complex angles

- CNC turning delivers perfect concentricity

- Wire EDM creates intricate shapes with electrical discharge

These combined technologies allow for exact and repeatable production.

2. The Engineer’s Dilemma: Critical Sourcing Decisions That Define Performance

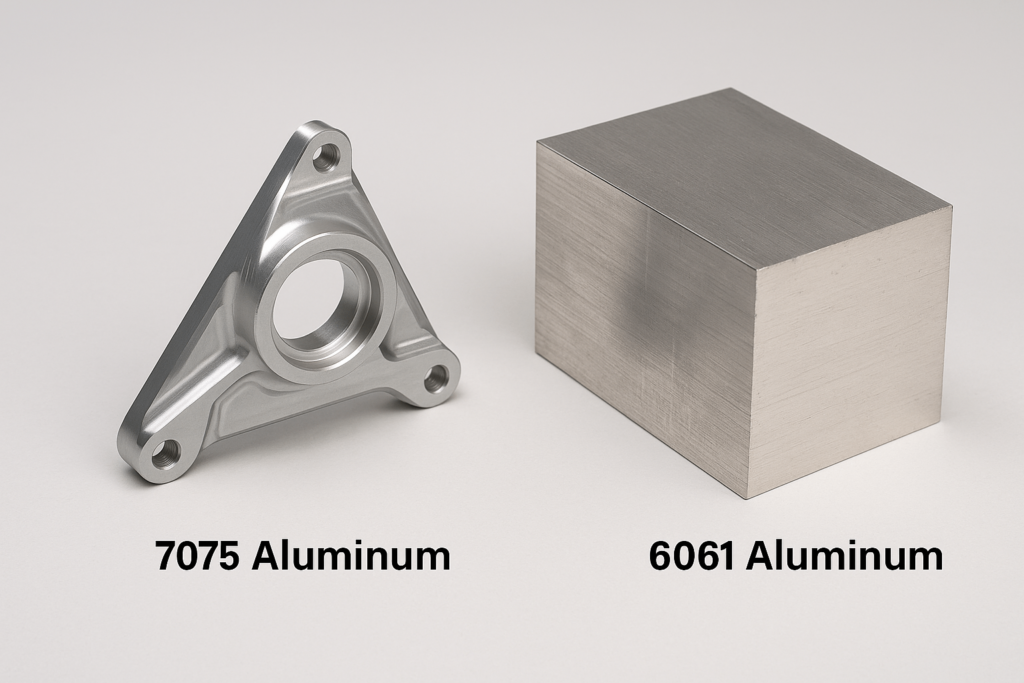

Material Choice: 7075 vs. 6061 Aluminum

When designing suspension components, engineers often choose between 7075 and 6061 aluminum.

7075 aluminum provides nearly double the tensile strength of 6061. Its high strength-to-weight ratio makes it ideal for high-stress parts like suspension arms. But machining 7075 takes longer and costs more. It’s also not weldable.

6061 aluminum, by contrast, is affordable, weldable, and easy to machine. It’s a better option for mounting brackets or tanks.

| Feature | 6061-T6 | 7075-T6 | Application Insight |

|---|---|---|---|

| Strength | 310 MPa | 570 MPa | 7075 for critical load parts |

| Yield Strength | 270 MPa | 490 MPa | Longer service life with 7075 |

| Machinability | Excellent | Good | 6061 reduces tooling cost |

| Weldability | Yes | No | 6061 allows more complex assemblies |

| Cost | Lower | Higher | 7075 reserved for crucial areas |

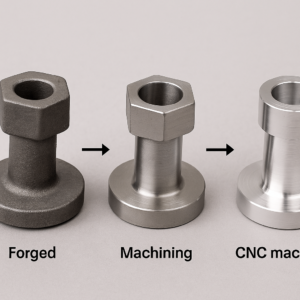

Forging vs. Machining: Why Combine Both?

Consider engine connecting rods. Forging aligns the metal’s grain, giving the part toughness and fatigue resistance. But forgings can’t meet exact tolerance requirements.

That’s why high-performance teams often start with a forged blank and finish it with CNC machining. This hybrid approach delivers both durability and precision.

Why 4130 Chromoly Wins in Chassis Fabrication

Chassis builders need materials that are light, strong, and weldable. 7075 aluminum fails this test due to its poor weldability.

4130 Chromoly offers an ideal alternative. It’s strong enough to allow thinner wall tubing. Plus, with proper pre-heat and post-weld treatment, it welds reliably.

This combination makes it the go-to choice for roll cages, suspension mounts, and chassis structures.

3. The Proving Grounds: CNC in Real Racing Applications

Rally Racing: Surviving Brutal Conditions

In rally, components face dirt, jumps, and vibration. CNC-machined control arms made from 7075 aluminum or 4130 steel resist cracking and deformation. The precision fit prevents premature wear.

Drag Racing: Handling Extreme Torque

Drag cars need parts that transfer power efficiently. CNC-machined straight-cut gears reduce axial loads and boost power delivery. Balanced billet flywheels made from steel stabilize launches.

EV Racing: Managing Weight and Heat

EV motors generate significant heat. CNC-machined cooling plates and battery enclosures made from 6061 aluminum help regulate temperature. Their lightweight design enhances performance.

4. From Design to Delivery: Building a Manufacturing Partnership

Why Process Matters

A good supplier does more than make parts. They help you design parts for manufacturability (DFM), review your CAD, and highlight production risks early.

YISHANG offers OEM CNC metal fabrication for vehicles. We manage the entire process, including prototyping, small-batch sampling, and scalable production.

We support:

- Low MOQs

- Custom surface finishes

- Protective packaging

- Export documentation

If you’re searching for a CNC racing parts manufacturer in China, our team delivers with consistent quality and transparent workflows.

Quality Assurance Backed by Certification

YISHANG’s processes follow ISO 9001 standards. Our quality control includes:

- Material traceability back to certified mills

- Real-time in-process inspection with machine probes

- Final verification using Coordinate Measuring Machines (CMMs)

This level of detail supports demanding clients in motorsports, aerospace, and other sectors needing precision metal parts for motorsports.

5. Mechanical Precision Powers Digital Accuracy

CNC doesn’t just create physical components. It underpins the digital systems that measure car performance.

For example, a misaligned sensor mount can send faulty data. CNC ensures brackets and structures stay perfectly rigid under load, giving accurate telemetry readings.

Teams use this data to optimize setups. They can trust that any changes reflect real-world behavior—not part inconsistencies.

6. Future Tech: AI Meets CNC

Generative Design Requires Precision Execution

AI-generated parts often have complex, organic shapes. They may reduce weight by 20% or more without compromising strength. But these shapes are only useful if a machine shop can reproduce them.

CNC ensures that once the AI delivers a design, the part performs as intended. YISHANG’s CNC workflow bridges the gap between simulation and reality.

Hybrid Manufacturing: 3D Printing + CNC

Some teams start with metal 3D printing to produce intricate shapes. Then they use CNC to finish the part to spec.

This method combines design freedom with engineering precision—ideal for low-volume, high-performance components.

Frequently Asked Questions (FAQ)

❓ What industries benefit most from CNC racing parts?

🟢 CNC racing components are widely used in motorsports, automotive manufacturing, electric vehicles (EVs), off-road vehicles, and other performance-critical sectors requiring high-tolerance precision metal parts.

❓ Does YISHANG offer OEM/ODM CNC services for large orders?

🟢 Yes. YISHANG specializes in bulk CNC metal parts manufacturing with flexible OEM/ODM services, ISO 9001 quality control, and RoHS compliance. We support large-scale production and low MOQ.

❓ What materials can be CNC machined for motorsports?

🟢 YISHANG supports CNC machining in aluminum (6061, 7075, 6063), stainless steel (304/316), carbon steel, chromoly 4130, red copper, and brass—ideal for structural and functional motorsport parts.

❓ What makes CNC machining better than forging for racing components?

🟢 CNC offers unmatched dimensional accuracy and consistency—ideal for components requiring tight tolerances, perfect mating surfaces, or post-processing for AI-generated parts. Forging provides superior internal grain strength, but both are best combined.

❓ Can YISHANG handle global shipping and documentation for CNC racing parts?

🟢 Yes. YISHANG exports to over 50+ countries with full support for documentation, export compliance, protective packaging, and global logistics coordination.

Conclusion: Why YISHANG is the Right Partner

Racing rewards precision. From suspension arms to cooling plates, every component must be right—every time.

With over 26 years in metal fabrication and CNC machining, YISHANG helps clients turn high-performance ideas into production-ready parts. Our expertise in custom CNC racing parts, combined with RoHS and ISO 9001 certifications, means your project is in capable hands.

💡 Looking for a CNC racing parts supplier in China with global experience and certified processes? Contact YISHANG for engineering support, prototyping, and full-scale production today.