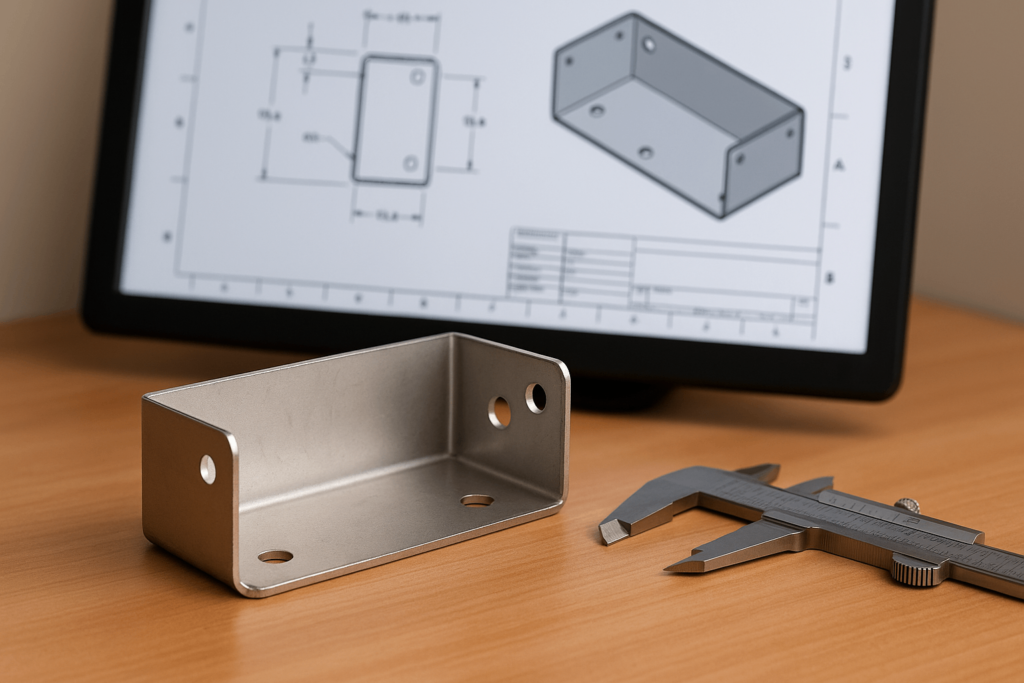

For procurement managers and engineers, an enclosure is more than a box; it’s a critical decision point that impacts timelines, budgets, and final product quality. Choosing between a standard solution and a custom sheet metal chassis requires a strategic perspective that goes far beyond the initial price tag.

This playbook is designed for decision-makers. It moves past basic specifications to provide a clear framework for evaluating the true cost, mitigating risks, and selecting a manufacturing partner capable of delivering consistent value. We will explore how strategic design and fabrication choices for your custom electronics enclosure can become a significant competitive advantage—especially when supported by a trusted OEM/ODM partner like YISHANG, a seasoned ISO 9001 certified sheet metal manufacturer with over 26 years of specialized experience in global B2B supply chains.

Act I: The Strategic Decision Table—Is Customization a Cost or an Investment?

The initial choice between a custom and an off-the-shelf enclosure is a critical inflection point. For a B2B buyer, this isn’t just about design; it’s a calculated decision about long-term value, supply chain efficiency, and return on investment (ROI).

The “Cost Illusion” of Off-the-Shelf Enclosures

Commercial Off-the-Shelf (COTS) solutions offer the tempting combination of low upfront cost and immediate availability. For early-stage prototyping, this can be a viable path to validate a concept quickly.

However, for production runs, this initial saving often masks significant downstream expenses. A standard enclosure can force design compromises, leading to inefficient internal layouts, the need for additional mounting hardware, and compromised thermal performance. These issues translate directly into higher assembly labor costs and an increased risk of field failures.

A Total Cost of Ownership (TCO) analysis provides a more accurate financial picture. This framework evaluates all direct and indirect costs over the product’s lifecycle, offering a clearer view of the true investment.

| TCO Factor | Off-the-Shelf (COTS) Enclosure | Fully Custom Enclosure |

|---|---|---|

| Acquisition Cost | Low unit price. | Higher unit price + potential NRE. |

| Design & Rework Costs | High hidden costs from design compromises, internal brackets, and inefficient space usage. | NRE is invested upfront to eliminate downstream rework. |

| Assembly & Labor Costs | Increased assembly time and labor due to non-optimized layout and extra hardware. | Optimized for DFMA principles, reducing assembly steps and labor costs. |

| Performance & Risk Costs | Higher risk of thermal failure, EMC compliance issues, and warranty claims due to suboptimal design. | Engineered for specific thermal and EMI shielding needs, mitigating risks of costly redesigns and compliance failures. |

| Brand & Maintenance Costs | Generic appearance can dilute brand identity. Difficult access can increase field service costs. | Purpose-built for brand aesthetics and serviceability, enhancing brand value and reducing long-term maintenance expenses. |

This TCO framework demonstrates how a custom solution, through value engineering, can significantly lower the total cost by mitigating risks and streamlining production, making it a sound long-term investment. Experienced OEM sheet metal partners like YISHANG help you navigate this shift early to maximize value.

Decision Tree: A Phased Approach to Your Project

The right choice depends on your project’s maturity. A phased approach ensures you are making the most cost-effective decision at every stage, from a single unit to a full production run.

- Prototype Validation Stage (Quantity 1): The primary goal here is rapid iteration. A standard enclosure or alternative rapid prototyping services like 3D printing can be the most efficient way to test form and fit without significant investment.

- Low-Volume Production & Market Testing: For initial runs, a modified standard enclosure can be an effective bridge. This involves customizing a stock product with necessary cutouts or features, balancing cost with specific needs.

- Scaling to Production (Up to 5,000+ Parts): As your production scales, the economic case for a fully custom metal enclosure becomes compelling. The efficiencies in assembly, material optimization, and reduced labor costs deliver a strong ROI. At this stage, working with a manufacturing partner like YISHANG—skilled in high-volume custom fabrication—ensures process control and consistent quality.

Act II: The Materials Scientist’s Lab—Choosing the DNA of Your Chassis

Material selection is a foundational decision that directly impacts cost, performance, and long-term reliability. For a procurement professional, understanding these trade-offs is key to de-risking the final product and ensuring it meets all specifications. A manufacturer with deep material knowledge—like YISHANG, which offers DFM consulting for metal parts and works with aluminum, stainless steel, carbon steel, and more—can help make the optimal choice.

Material Trade-Offs: Strength, Weight, and Cost

- Aluminum is lightweight, corrosion-resistant, and ideal for heat dissipation. It’s widely used in telecom and server applications. However, it is more prone to deformation during forming and welding.

- Cold-rolled steel is cost-effective and strong, suitable for indoor equipment, but requires coatings (like powder coating or plating) for corrosion protection.

- Stainless steel (304/316L) is ideal for hygiene-critical or corrosive environments. It is heavier and more expensive but provides unmatched chemical and microbial resistance.

YISHANG’s experienced engineers can help clients navigate these trade-offs based on real-world application scenarios—whether it’s a chassis for food processing machinery or outdoor telecom cabinets.

Act III: DFM Principles—From Concept to Production-Ready

Design for Manufacturability (DFM) is the bridge between engineering intent and production reality. Poor DFM choices result in production delays, excessive scrap, and quality inconsistencies. A mature DFM strategy is one of YISHANG’s strongest value-adds, with over two decades of expertise in OEM sheet metal fabrication services.

Key DFM Guidelines for Sheet Metal Chassis

- Bend Radius: Maintain a minimum bend radius equal to the material thickness to avoid cracking.

- Hole-to-Edge Distance: Keep punched holes at least twice the material thickness away from edges to prevent distortion.

- K-Factor & Bend Allowances: Precise values for different materials ensure accurate flat pattern layouts and reduce rework.

- Fastener Strategy: Choose between weld nuts, PEM inserts, or self-clinching studs based on access and stress profile.

YISHANG’s design support team helps validate every project’s CAD drawing for these principles before tooling begins, reducing the risk of trial-and-error and compressing the development timeline.

Act IV: Designing for High-Stakes Environments

Some chassis don’t just protect electronics—they ensure uptime in mission-critical environments. For industries like aerospace, medical devices, and energy storage, enclosure failure isn’t an inconvenience—it’s a liability.

Examples of Application-Specific Enhancements

- Medical Enclosures use stainless steel chassis for medical devices, typically in 316L grade, and require biocompatible coatings and smooth weld seams to meet GMP or FDA requirements.

- Aerospace Components often utilize isogrid or honeycomb backplanes in aluminum for optimal stiffness-to-weight ratio.

- Outdoor or Marine Equipment integrates IP-rated gaskets, drain holes, and multi-layer finishes to survive exposure.

YISHANG’s engineering team has developed custom chassis for such industries, tailoring designs to ensure regulatory compliance and long-term durability under extreme conditions.

Act V: Selecting Your Manufacturing Partner—Beyond the Quote

The final step is choosing a manufacturing partner who is not just a vendor, but a collaborator. A well-equipped ISO 9001 certified sheet metal manufacturer like YISHANG contributes at every phase—from design review to inspection-ready delivery.

Checklist for Evaluating Sheet Metal Suppliers

- Experience & Industry Fit: Does the supplier have relevant experience with similar products or industries?

- Production Capabilities: Can they handle your batch sizes and tolerance requirements using CNC, laser cutting, and robotic welding?

- Quality Systems: Are they ISO 9001 certified and do they perform incoming material inspection, in-process checks, and final QC?

- Design Support: Do they offer manufacturability analysis, material consulting, and quick prototyping?

- Logistics Readiness: Can they support international delivery, offer custom packaging, and meet your project deadlines?

At YISHANG, these capabilities are not add-ons—they are part of the standard project pipeline. Our team routinely works with overseas B2B clients in industries ranging from energy to agriculture, ensuring smooth communication and on-time project delivery.

Conclusion: The Strategic Advantage of Going Custom

A custom metal enclosure for electronics is more than a technical solution—it’s a strategic asset. With a partner like YISHANG, you gain access to decades of expertise, material guidance, and scalable production excellence.

Whether you’re launching a new product, redesigning for scale, or entering regulated industries, your chassis partner should act as a trusted extension of your engineering and sourcing team.

Ready to design your next custom chassis with confidence? Contact YISHANG for expert consultation, rapid prototyping, and scalable manufacturing—trusted by businesses in 50+ countries.