Introduction: The Zinc Conundrum

If you’re sourcing large volumes of metal components for industrial use, you’ve likely asked: Does zinc rust? The short answer—no, but there’s more to understand.In practice, there is no true zinc rust—what buyers often call rust is actually a gray patina formed by oxidation.

For procurement managers and industrial buyers, choosing the right protective coating isn’t about chemistry—it’s about ensuring your product withstands real-world conditions with minimal maintenance. This guide examines how zinc behaves in corrosion-prone environments, what coating options suit which conditions, and how you can avoid common sourcing pitfalls.

Whether you operate in energy infrastructure, automotive assembly, agriculture, or appliance manufacturing, understanding zinc’s corrosion characteristics can help reduce warranty claims, lower lifecycle costs, and ensure reliable performance in end-use markets.

Explore our zinc-coated enclosures for outdoor and industrial applications. YISHANG offers zinc coating for outdoor enclosures, vending machine shells, electrical cabinets, and custom industrial housing solutions—ideal for buyers seeking corrosion-resistant outdoor components.

Will Zinc Rust? Can Zinc Rust Outdoors?

Yes and no. Zinc doesn’t rust like steel—instead, it forms a protective gray patina that slows further corrosion. That’s why zinc-coated parts are common in outdoor industrial applications.

For clarity, when buyers ask “can zinc rust,” they are usually referring to surface oxidation or white residue, not true rust.

When Zinc Meets Air: Understanding Patina, Not Rust

Zinc doesn’t rust in the traditional sense. It oxidizes, but this oxidation forms a passive, protective barrier rather than destructive rust flakes.

When exposed to air, zinc develops a patina made up of zinc oxide and zinc carbonate. This dull gray layer stabilizes the surface, reducing further exposure to moisture and oxygen. It’s what makes zinc-coated steel survive for decades in the right conditions.

However, in highly acidic or chloride-rich atmospheres—such as coastal installations or polluted urban zones—this protective layer can dissolve. If that happens faster than it reforms, corrosion accelerates.

This is where your environment-to-coating match becomes crucial. Sourcing components without specifying coating thickness or atmospheric class (ISO 9223) is one of the most common causes of premature failure.This distinction matters because many sourcing documents casually call it zinc rust, even though technically it is oxidation.

For added protection, some applications use a combination of zinc passivation and top-layer sealants to extend corrosion resistance in harsh zones.

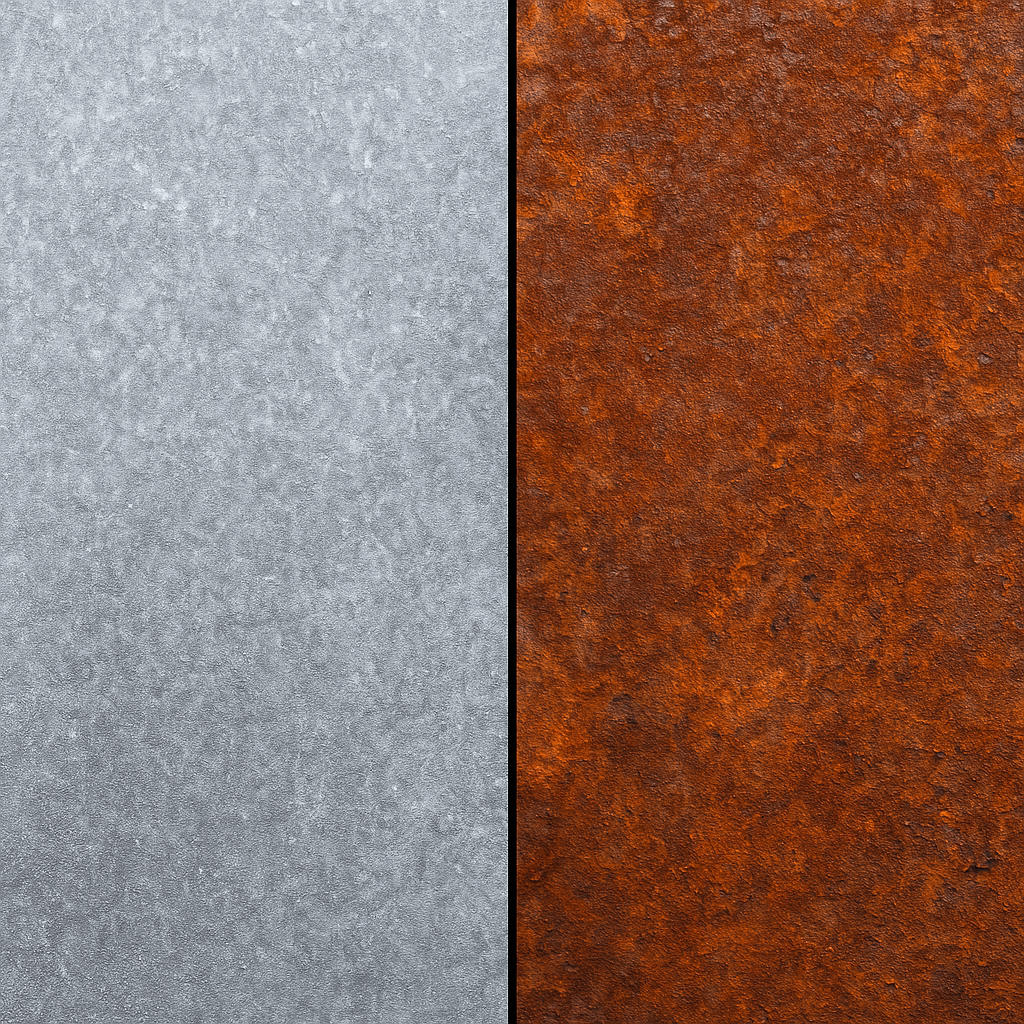

How Does Zinc Compare to Steel in Corrosion Behavior?

| Metal | Rusts? | What It Forms | Protection Behavior |

|---|---|---|---|

| Steel | Yes | Red-brown rust | Flakes, exposes metal |

| Zinc | No | Gray-white patina | Seals and protects base metal |

Zinc Rust vs Corrosion vs Oxidation: Speaking the Same Language

Rust is specific to iron and its alloys. Zinc doesn’t rust—it corrodes, and in many cases, that corrosion is intentional and beneficial.

In zinc-coated parts, oxidation leads to a protective surface layer. This is different from rust on steel, which flakes away and exposes fresh metal. That’s why zinc is used as a sacrificial layer—it corrodes to shield the base metal.

The only time oxidation becomes a concern is when white rust appears—typically due to improper storage during shipping. White residue is often mistaken for zinc rust, but it is actually zinc hydroxide carbonate. It’s usually harmless early on but can reduce overall protection if allowed to build up.

If you’re shipping large quantities of galvanized parts overseas, ensure your supplier uses breathable packaging and moisture absorbers. This small step can prevent cosmetic returns and logistical headaches.

For projects requiring anti-corrosion enclosure solutions or steel cabinet protection, proper finish selection is essential to avoid performance degradation in the field.

Galvanic Protection: Why Zinc Sacrifices Itself to Save Steel

Zinc doesn’t just form a passive barrier—it acts as a sacrificial anode in galvanic protection systems.

When zinc-coated steel is exposed to moisture or electrolytes, zinc—being more electrochemically active than iron—corrodes first, protecting the underlying steel even if the coating is scratched or damaged.

This galvanic behavior makes zinc ideal for outdoor steel protection. Even small coating breaches continue to protect surrounding areas.

⚠️ Design Tip: In multi-metal assemblies, check for potential galvanic mismatch. For example, zinc touching copper can accelerate zinc loss.

Zinc vs Other Protective Coatings – Durability & Cost Snapshot

| Coating Type | Outdoor Durability | Cost | Notes |

|---|---|---|---|

| Hot-Dip Galvanized | ★★★★☆ (10–50 yrs) | $$ | Best for rugged outdoor use |

| Electroplated Zinc | ★★☆☆☆ (2–5 yrs) | $ | Best for indoor parts |

| Powder Coating | ★★★☆☆ | $$$ | Strong but needs surface prep |

| Stainless Steel | ★★★★★ | $$$$ | No rust but high cost |

Which Zinc Coating Method Should You Use? [Quick Comparison]

| Zinc Coating Type | Thickness Range | Outdoor Durability | Typical Use Case | Notes |

|---|---|---|---|---|

| Electroplated Zinc | 5–25 µm | 1–5 years | Indoor components, fasteners | Cost-effective, not suited for marine areas |

| Hot-Dip Galvanized | 55–100 µm | 10–50+ years | Structural steel, enclosures | Best for rugged outdoor use |

| Zinc-Aluminum Alloy | 25–75 µm | 15–60 years | Coastal, industrial, cut edges | Stronger corrosion resistance, thinner layer needed |

📌 Engineering Insight: Use alloy coatings (Zn-Al or Zn-Mg) in high-salinity or coastal environments for extended protection, especially on edges.

How Long Does Zinc Really Last? Performance by Environment

Zinc’s lifespan varies drastically by exposure type. It performs best in rural, low-sulfur environments and degrades fastest in high-salinity or industrial atmospheres.

According to ISO 9223:

In rural zones, hot-dip galvanized coatings (≥85μm) last 50+ years.

In coastal or industrial zones, the same coating may degrade in under 15 years.

| Environment | Coating Thickness (μm) | Expected Lifespan |

|---|---|---|

| Rural | 85 | 50+ years |

| Urban | 85 | 25–40 years |

| Coastal | 85 | 10–20 years |

| Industrial | 85 | 8–15 years |

According to ISO 9223, environmental categories range from C1 (indoor, dry) to C5 (industrial or coastal).

✔ In C2 environments (rural, low-pollution), hot-dip galvanized steel lasts over 50 years

✔ In C4 (urban/industrial), ≥85µm coating may last 15–20 years with proper surface prep

✔ In C5 (coastal), alloy coatings or duplex systems (zinc + powder) are highly recommended

When sourcing parts, always specify environmental exposure class and expected lifespan—not just “zinc-coated”—to avoid early failure.

Common Assembly & Handling Errors That Reduce Zinc Performance

Even with a high-quality zinc coating, poor handling or design can undermine protection:

Overlapping components with no drainage lead to water traps and corrosion hotspots

Non-breathable packaging during shipping causes white rust formation

Direct contact with copper or stainless steel can trigger galvanic corrosion

✅ Best Practices:

- Add weep/drain holes in enclosed metal designs (to prevent zinc rust hotspots and moisture traps)

- Use desiccants and breathable wraps during export (helps prevent zinc rust, also known as white rust)

- Electrically isolate dissimilar metals using washers or coatings (reduces galvanic loss sometimes mistaken as zinc rust)

Frequently Asked Questions

Q: Does zinc plating prevent rust completely?

A: Zinc plating provides sacrificial protection for steel, but its effectiveness depends on thickness, environment, and exposure. In harsh settings, thicker coatings or dual-layer protection are recommended.

Q: What is the best zinc coating method for outdoor use?

A: Hot-dip galvanizing (HDG) is most durable for outdoor conditions, offering thicker coatings and metallurgical bonding that withstand decades of exposure.

Q: Can I use zinc-coated parts in coastal or marine environments?

A: Yes, but only with proper coating specifications (≥85 μm) and protective packaging. Combining HDG with a topcoat can further extend service life.

Q: Is white rust dangerous?

A: White rust is mostly cosmetic early on but may compromise protective layers if left unchecked. It’s preventable with correct storage and packaging during transit.

Q: What certifications should I look for when sourcing zinc-coated parts?

A: Look for compliance with ISO 1461, ISO 14713, ASTM A123, and RoHS. Ask for salt spray test reports and material traceability for added confidence.

Q: Will zinc rust in rain or humid environments?

A: No. There is no true zinc rust. Instead, zinc forms a protective oxide layer when exposed to moisture. In harsher settings, thicker coatings are needed.

Q: Is the white residue on zinc rust?

A: That’s white rust—often misidentified as zinc rust. It is mostly cosmetic early on, but avoid build-up with breathable packaging and dry storage.

Conclusion: Zinc-Coated Parts Require Smart Sourcing, Not Just a Quote

Zinc may not rust like steel, and there is no true zinc rust, but it is not immune to degradation. Its effectiveness depends on correct application, coating choice, and handling.

For wholesale buyers, especially those exporting or installing products in aggressive environments, understanding zinc behavior isn’t optional—it’s strategic. Better specs mean longer lifespans, lower maintenance costs, and happier customers.

YISHANG manufactures custom zinc-coated components including enclosures, brackets, housings, vending machine shells, and signage frames—built to perform in demanding outdoor environments.