Introduction: The Tale of Two Panels—One to Hide, One to Protect

Every building has one: the gray metal box that serves as the nerve center of its electrical system. For homeowners, it’s often an eyesore, sparking a search for creative electrical panel cover ideas and breaker box cabinet ideas.

For engineers and procurement managers, however, that same box is a critical asset. This guide bridges that gap by starting with safe, creative residential solutions. It then pivots to the high-stakes world of industrial applications.

Here, the conversation shifts from aesthetics to engineering. In this context, a “cover” becomes a mission-critical industrial electrical enclosure, and the objective expands—no longer just to hide, but to protect, comply, and ensure sustained, dependable performance.

Residential Solutions—Safely and Beautifully Hiding Your Breaker Box

The Golden Rule Before You Cover Anything: A Panel’s “Personal Space”

Before any decorative cover is considered, the non-negotiable safety zone around an electrical panel must be respected. This requirement, outlined in the National Electrical Code (NEC), ensures unrestricted access for maintenance and emergencies.

Ignoring these electrical panel clearance requirements can lead to a serious hazard. Therefore, understanding these spatial needs is essential.

- The 3-Foot Bubble: The NEC requires a clear working space of at least 36 inches deep and 30 inches wide in front of the panel. This area must remain completely unobstructed.

- Headroom and Reach: This clear space must extend vertically to a height of at least 78 inches (6.5 feet). Additionally, the highest circuit breaker handle should not exceed 79 inches from the floor.

- The 90-Degree Swing: The panel’s metal door must be able to open a full 90 degrees without obstruction from walls, furniture, or decorative covers.

7 Clever & Code-Compliant Ways to Hide Your Breaker Box

With safety as the priority, here are several practical DIY electrical panel cover solutions that also maintain accessibility.

- The Hinged Artwork Disguise: One of the most classic solutions is to cover an electrical panel with a lightweight canvas or framed print mounted on hinges. This design allows you to swing it open like a door.

- The Functional Command Center: A framed chalkboard or corkboard mounted over the panel can double as a message center for kitchens or home offices. You can hang it on hooks for easy tool-free removal.

- The Mirror Trick: A large, leaning mirror in a hallway conceals the panel and makes the space feel more open. Just make sure it can be moved easily and isn’t permanently affixed.

- The Seamless Cabinet: For a more integrated solution, you can install a shallow custom cabinet that matches existing cabinetry. This cabinet must exclude a back and must not intrude on the required 36-inch clearance.

- The Paint & Mural Camouflage: Simply painting the panel door to match the wall provides quick concealment. Alternatively, a mural that incorporates the panel’s shape can blend it into the surrounding decor.

- The Renter-Friendly Tapestry: A macrame wall hanging or textile, attached with magnets or removable strips, offers a removable and damage-free solution.

- The Sliding Barn Door Accent: A small barn door mounted on a track adds rustic charm while ensuring the panel remains fully accessible.

The Professional’s Guide—From Aesthetics to Engineering

When a “Cover” Becomes a Mission-Critical “Enclosure”

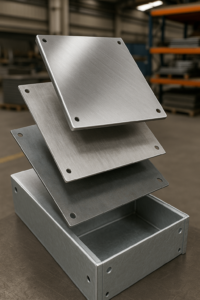

In industrial and commercial settings, the mindset shifts dramatically. Here, the goal isn’t just concealment—it’s protection. The “cover” now functions as a robust industrial electrical enclosure engineered to safeguard vital systems.

As a result of evolving safety regulations, the 2023 NEC (Section 312.102) mandates that enclosures be equipped with manufacturer-provided doors. This change prohibits uncertified, homemade solutions and reinforces the need for precision-engineered products.

Industrial Enclosure Design—Materials, Fabrication & Finish

A high-performance custom sheet metal electrical enclosure must be designed as an engineered system. From the viewpoint of a procurement manager, the materials and manufacturing methods used directly affect the total cost of ownership (TCO).

The Core Material – A Strategic Choice for Longevity

The selection of base metal is crucial. The correct choice depends entirely on the environment in which the enclosure operates.

- Carbon Steel: Known for strength and cost-efficiency, carbon steel enclosures are often used indoors. However, their durability depends heavily on the quality of the finish.

- Aluminum: If weight reduction is a priority, aluminum enclosures provide natural corrosion resistance without compromising strength.

- The Molybdenum Advantage (304 vs. 316 Stainless Steel): For harsh conditions, stainless steel NEMA enclosures are preferred. Grade 316, which includes 2–3% molybdenum, resists chloride pitting significantly better than Grade 304. This makes it ideal for marine, food, and chemical environments. Investing in Grade 316 upfront helps prevent future replacement costs.

The Precision Cut – Why Laser Cutting Matters

The integrity of an enclosure depends on precise manufacturing. Therefore, modern fiber lasers are used to cut enclosure panels with tolerances as tight as ±0.05 mm.

This technique ensures accurate fits, reduces the need for secondary finishing, and results in burr-free, ready-to-assemble components. Ultimately, this improves both sealing and appearance.

The Protective Skin – Powder Coating vs. Paint (Durability & Cost)

For carbon steel enclosures, the finish plays a critical role. Between powder coating vs. paint, powder coating stands out due to its thickness and durability.

A high-quality powder coat, applied properly, can last up to 20 years. In comparison, industrial liquid paint may require re-coating or frequent maintenance.

| Feature | Powder Coating | Industrial Liquid Paint |

|---|---|---|

| Durability & Hardness | Superior (4–10x thicker) | Good to Very Good |

| Resistance (Chip, Scratch, Fade) | Excellent | Moderate to Good |

| Finish Consistency | Excellent (No drips/runs) | Operator-dependent |

| Environmental Impact (VOCs) | Near-Zero | Contains Solvents |

| Long-Term Cost (TCO) | Lower (less maintenance) | Higher (requires more upkeep) |

Decoding Protection Ratings: NEMA & IP for Procurement

The enclosure’s location and function determine which rating you need. Understanding NEMA vs. IP ratings allows you to specify the right product confidently.

- Scenario 1: Food Processing Plant

- Your Shield: NEMA 4X / IP66. These enclosures protect against corrosion and withstand high-pressure washdowns.

- Scenario 2: Indoor Factory with Dust and Drips

- Your Shield: NEMA 12 / IP54. These models guard against airborne particles and light splashes.

- Scenario 3: Coastal Outdoor Installations

- Your Shield: Weatherproof Metal Enclosure with NEMA 4X. Combined with 316 stainless steel, this setup offers top-tier corrosion protection.

The Hidden Specs That Secure Your Business: Quality & Compliance

Certifications may seem secondary, but in reality, they prevent costly setbacks and ensure operational consistency.

- ISO 9001 Certification: This signals that the manufacturer uses a repeatable and audited quality process. You benefit from consistency across all units—whether it’s the first batch or the thousandth.

- RoHS Compliance: Enclosures that fail RoHS restrictions can result in your product being banned from global markets. Therefore, sourcing from a RoHS-certified metal enclosure manufacturer is essential.

With 26+ years of experience and exports to over 50 countries, YISHANG is a trusted supplier of RoHS-certified, ISO 9001-compliant metal enclosures tailored to global standards.

Conclusion: The Right Enclosure for the Right Application

Whether it’s a hinged artwork at home or a custom NEMA-rated enclosure in a facility, the solution should always suit the environment. For residential users, visual integration and code compliance matter most. However, for industrial buyers, reliability and certification are paramount.

Settling for an off-the-shelf product may cost you more in the long run. Instead, design your enclosure around your environment.

Call to Action

Your project has unique environmental and compliance challenges. Contact our engineering experts at YISHANG to design a custom sheet metal electrical enclosure that protects your critical assets. Our team is ready to help you select the ideal RoHS-compliant solution for your industry.