Why Enamel Paint Still Matters for Metal Product Buyers

Buyer’s Perspective: For global sourcing professionals working with metal enclosures, displays, kiosks, or vending systems, selecting the right industrial coating can make or break a project. Enamel paint remains a highly practical option in bulk production thanks to its durability, rework flexibility, and international compliance.

Whether for export-grade mild steel cabinets or signage exposed to the elements, understanding enamel paint from a procurement perspective helps ensure performance, regulatory alignment, and logistics readiness.

This guide walks you through how to assess, specify, and apply enamel paints efficiently in your supply chain.

What Is Enamel Paint and Why It Matters in Bulk Metal Coating Projects

Enamel paint is a resin-based protective coating that cures into a hard, glossy, and weather-resistant film. It is widely used across industrial and structural metal applications.

Two major categories:

Solvent-based alkyd enamel: Durable with a high-gloss finish but emits moderate VOCs.

Water-based enamel (acrylic/urethane): Export-friendly, low-odor, REACH-compliant.

Common procurement use cases:

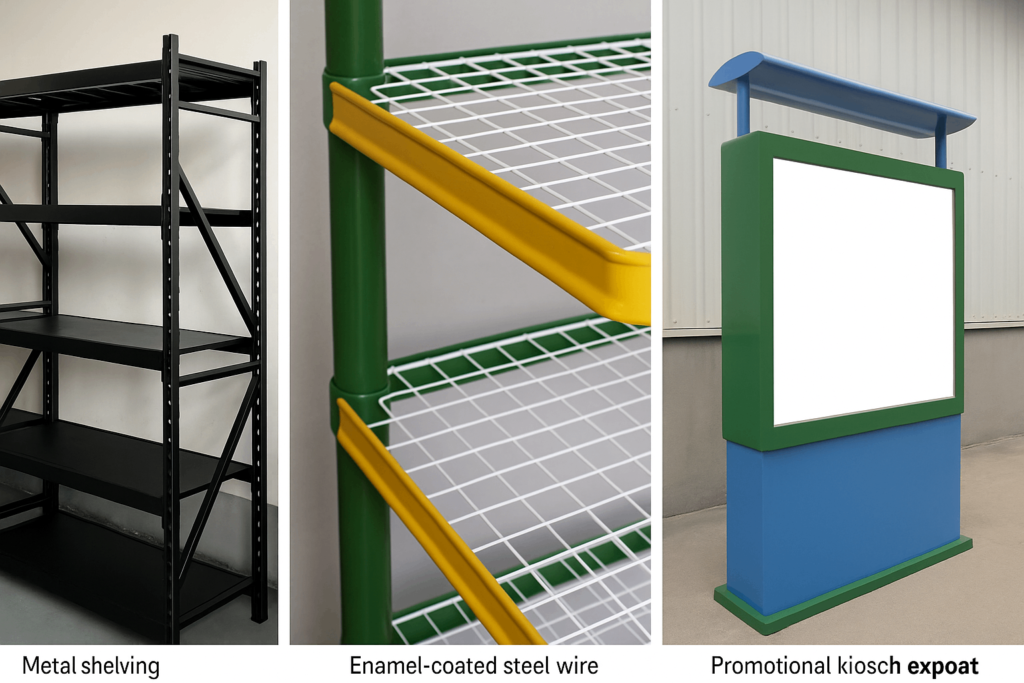

Steel vending housings and kiosks

Reworkable powder-coated racks

Outdoor-use mild steel hardware

Painted signage or steel shelving for logistics-ready deployment

What Is Enamel Paint Made Of? Technical Composition and Standards

Buyer’s Tip: Always require full TDS and SDS documentation before confirming an order.

Typical enamel formulations include:

Binders (alkyd or acrylic resins): Control adhesion and durability

Pigments: Deliver color, coverage, and corrosion protection

Solvents or water: Impact drying speed and sprayability

Additives: Enhance flow, gloss, and resistance properties

Standardized test metrics:

Adhesion: ASTM D3359 (4B–5B)

Gloss: ASTM D523 (>85 GU at 60°)

Salt spray: ASTM B117 (>250 hours)

Hardness: ASTM D3363 (2H–3H)

Use these figures during pre-qualification or factory audits.

When to Specify Enamel Paint (and When You Shouldn’t)

Application Warning: Match enamel use to operating conditions and base material.

Ideal for:

Exterior enclosures needing scratch-resistant gloss

Large-volume metal parts that require in-transit repairability

Economical runs where powder coating is overkill

Avoid when:

You need high flexibility or extreme UV resistance

Using untreated aluminum or galvanized steel (unless primed)

The product is for harsh marine or chemical exposure

Quick Match Matrix: Best Enamel Coating Uses for Metal Buyers

| Application | Enamel Paint Fit | Notes |

|---|---|---|

| Outdoor kiosks and cabinets | ✅ Yes | Use phosphate-treated steel and PU enamel |

| Aluminum profile frames for signage | ⚠ Partial | Must use etching primer underneath |

| Food-grade equipment frames | ❌ No | Epoxy or FDA-compliant PU recommended |

| Display racks for shipping | ✅ Yes | Allows for low-cost touch-up during transit |

Use this matrix to quickly align your part specs with coating options.

Enamel vs Epoxy vs Powder Coating: What Industrial Buyers Should Know

| Feature | Enamel Paint | Epoxy Paint | Powder Coating |

| VOC Compliance | Moderate–Low | Medium | Very Low |

| Substrate Flexibility | Low | Medium | Low |

| Touch-Up Feasibility | ✅ Easy | ⚠ Limited | ❌ Not feasible |

| Application Process | Brush/Spray | Spray | Electrostatic |

| Finish Repair Cost | Low | Moderate | High (requires oven) |

Use this table during feasibility reviews for coating methods.

Evaluating & Controlling Enamel Coating Quality

Buyer’s Tip: Always request a sample part finished on your actual substrate.

Before confirming bulk production:

Ensure your supplier’s TDS uses ASTM/ISO benchmarks

Ask for factory sample panel test reports (adhesion, gloss, corrosion)

Conduct basic field simulations (scratch, tape, drop)

During application:

Verify surface prep steps (e.g., degreasing, phosphating)

Monitor cure environment (humidity, airflow, oven time)

Require coating logs with batch-level traceability (TDS + SDS)

Why this matters: Most enamel failures arise not from poor paint—but from improper pretreatment or curing.

Eco Compliance in Enamel Systems for Export Buyers

Global markets demand increasing environmental accountability:

VOC limits (e.g., CARB <100 g/L, EU <130 g/L)

Toxicant bans: lead-free, chrome-free, no halogenated solvents

Reusable packaging & chemical registration

🛡️ Tip: When exporting to strict regions like California or Germany, explicitly request low-VOC enamel for export.

FAQ: Enamel Paint for International Procurement

Q1: Can enamel be applied directly to aluminum or galvanized steel?

Not reliably. Always apply an etching primer first to avoid peeling or adhesion loss.

Q2: Does high gloss equal higher durability?

No. Gloss is aesthetic. Corrosion resistance depends more on primer, film thickness, and resin type.

Q3: What tests should I ask for?

At minimum: ASTM D3359 (adhesion), D523 (gloss), B117 (salt spray), D3363 (pencil hardness).

Q4: Can enamel resist salt air or humidity?

Partially. If corrosion risk is high (e.g., coastal installs), opt for epoxy or PU + primer layers.

Q5: Enamel vs epoxy for mild steel components?

Epoxy offers stronger chemical protection. But enamel allows faster rework and logistics flexibility.

Q6: Is enamel suitable for RFQ specs in the EU or US?

Yes, with REACH- or CARB-compliant formulas. Always attach TDS with VOC data.

Should You Use Enamel for Your Next Batch?

Enamel paint remains a smart, versatile option for many industrial metal products—especially for buyers needing reliable performance, export compliance, and in-transit repair flexibility.

When specified correctly and matched with the right primer + process control, it reduces failure risk and supports large-batch production.

YISHANG offers technical advisory and coating validation support for global buyers. Reach out to check compatibility or request a pre-tested spec sheet for your product category.