Does Glass Really Have a Melting Point? Let’s Clarify

When industrial buyers search for the “melting point of glass,” they’re typically trying to determine if a particular glass type can perform in elevated temperature conditions. Unlike metals, glass does not melt at a single, defined point. Instead, it’s an amorphous solid—it softens gradually across a range of temperatures.

This behavior matters for those sourcing materials for applications like enclosures, inspection windows, or electronic housings. For soda-lime glass, softening starts well below the quoted 1400–1600°C, often around 730°C. Without understanding this thermal behavior, it’s easy to select the wrong material, leading to cracking, deformation, or failure in use.

📌 According to ASTM C338, the softening point of soda-lime glass is around 720–740°C. This is a critical temperature threshold in industrial environments.

Composition Dictates Performance

In B2B procurement, glass type selection needs to be based on functionality, not just naming conventions. The most widely used commercial glass—soda-lime—has the following composition:

| Component | Typical Percentage |

|---|---|

| Silicon Dioxide (SiO₂) | 70–75% |

| Sodium Oxide (Na₂O) | 12–15% |

| Calcium Oxide (CaO) | 5–10% |

| Other Oxides (Al₂O₃, MgO) | Trace amounts |

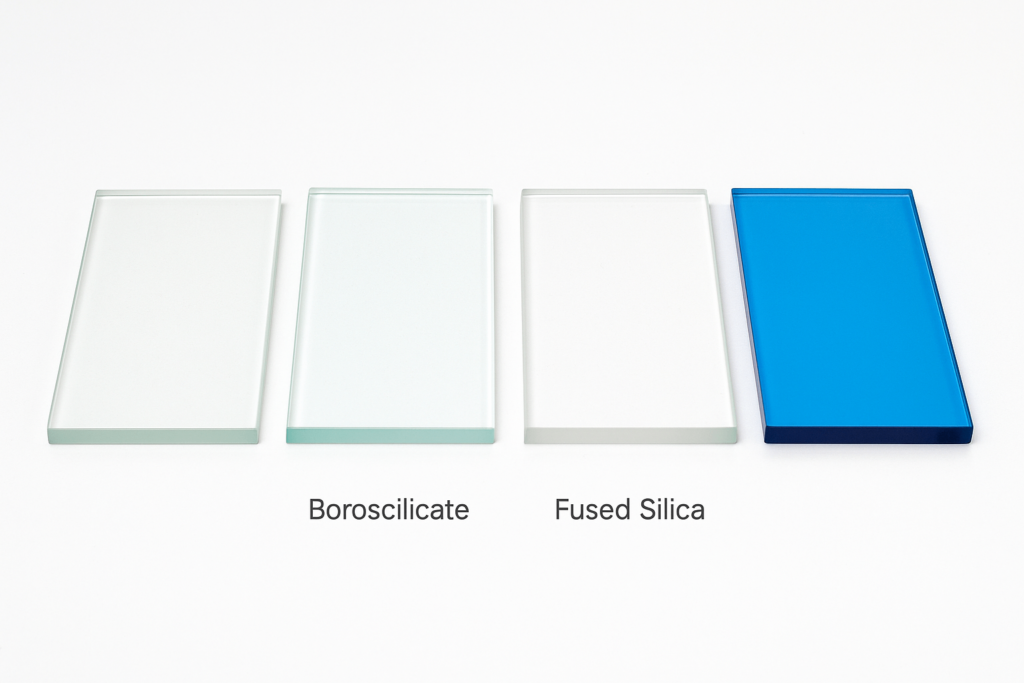

Other variants include:

- Borosilicate glass: Superior thermal shock resistance; ideal for equipment exposed to rapid heating/cooling.

- Fused silica: Withstands temperatures exceeding 1700°C; used in aerospace, semiconductor, and power applications.

Choosing the wrong glass type can result in costly mismatches. That’s why experienced buyers verify chemical composition and glass transition behavior before confirming a spec.

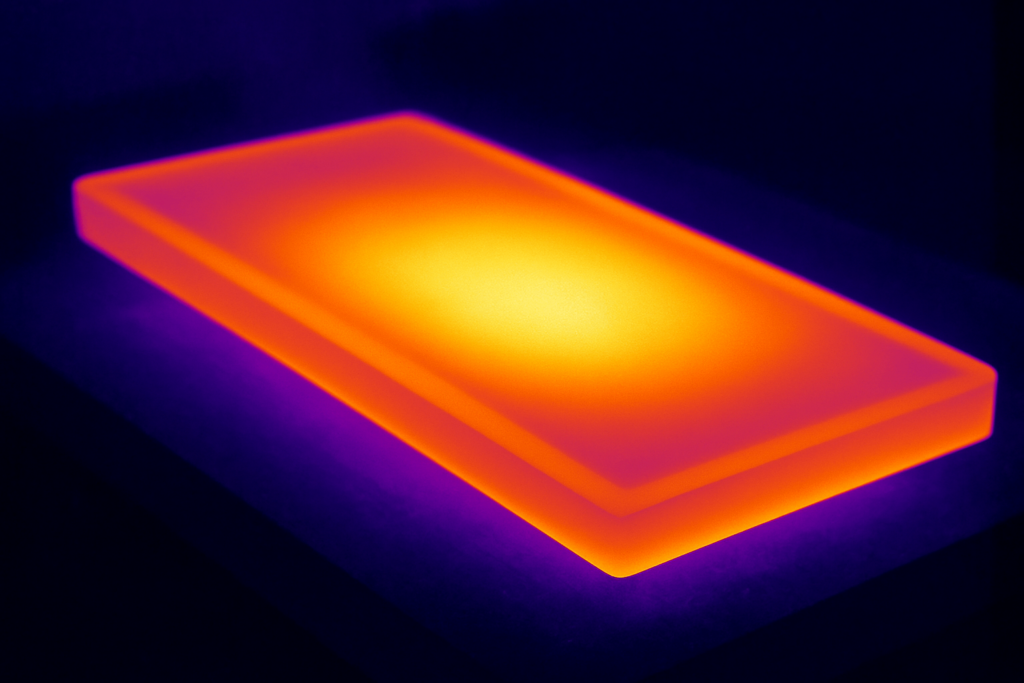

The Thermal Profile of Glass: Understanding Behavior Across Temperatures

Glass doesn’t transition from solid to liquid instantly. Its viscosity changes predictably over a thermal spectrum, defined by three main temperature points:

Glass Transition Temperature (Tg)

Around ~520°C (soda-lime), the structure begins to relax. Internal stress is relieved, but the glass remains dimensionally stable.

Softening Point

At ~730°C, glass begins to deform under its own weight. This defines when it can no longer maintain a rigid shape.

Working Point

At ~1000°C, the glass can be shaped or formed using standard industrial methods.

| Glass Type | Tg (°C) | Softening Point (°C) | Working Point (°C) |

|---|---|---|---|

| Soda-Lime | ~520 | ~730 | ~1000 |

| Borosilicate | ~560 | ~820 | ~1250 |

| Fused Silica | ~1200 | ~1665 | >1700 |

Understanding these values ensures that selected glass will perform as expected under real-world process conditions.

Real-World Variables That Affect Glass Performance

Standard glass types can still behave differently depending on how they’re manufactured and processed. Key influencing factors include:

- Material Purity: Trace metals like iron affect color and thermal absorption.

- Furnace Atmosphere: The chemical environment during melting (oxidizing/reducing) influences final composition.

- Thermal Treatment Profiles: Fast ramp-ups increase the risk of thermal shock; inconsistent cooling causes stress buildup.

- Flux and Stabilizer Content: Higher Na₂O levels make forming easier but reduce chemical durability.

📌 For bulk orders or critical applications, request performance certifications, test curves, and batch reports. A credible supplier will share technical documentation aligned with industry standards.

Glass in Metal Assemblies: Controlling Thermal Expansion Risk

When glass is installed in a metal framework, thermal expansion mismatch becomes a critical design factor. Common issues include:

- Stress fractures during heating/cooling cycles

- Delamination of seals or adhesives due to softening

- Edge cracking from mechanical over-constraint

✅ Example: An equipment viewport using borosilicate in a stainless steel frame must account for both materials’ coefficients of thermal expansion (CTE). If not, the glass may develop microcracks after thermal cycling.

📌 A YISHANG survey of 50+ metal-glass integrated enclosure projects revealed that 80% of failures were traced to CTE mismatches or inadequate mounting allowances.

Buyer’s Glass Selection Guide: Match Performance with Purpose

Whether you’re sourcing for food processing machinery or outdoor lighting, glass choice should reflect:

- Expected thermal exposure

- Required lifespan and mechanical stress

- Optical, chemical, or UV/IR performance needs

| Application Type | Recommended Glass | Reason |

|---|---|---|

| Furnace Ports | Borosilicate | Handles thermal shock, mid-level cost |

| Semiconductor Equipment | Fused Silica | Extreme heat resistance, optical clarity |

| General Enclosures | Soda-Lime | Affordable for stable environments (<200°C) |

| UV or IR Devices | Fused Silica | Transmits specific wavelengths reliably |

📌 Quick Glass Selection Flow:

→ Define Temperature Range → Check Environmental Stressors → Match with Glass Softening/Working Point → Confirm CTE Compatibility → Final Selection

🔎 Frequently searched phrases by B2B buyers:

- “glass panel for industrial oven doors”

- “fused quartz vs fused silica in high-temp setups”

- “high temperature glass inserts for enclosures”

Including these long-tail keywords supports better content targeting and higher page relevance in search algorithms.

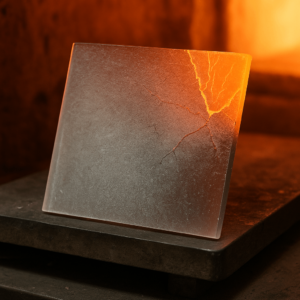

Where Things Go Wrong: Avoiding Common Glass Failures

Procurement-related failures typically result from assumption-based selection. Real examples include:

- A parts buyer approved soda-lime for oven windows—shattered within hours at 500°C.

- A UV lamp enclosure cracked after adhesives were cured too close to the glass’s softening point.

- A high-end laser sensor fogged permanently—glass lacked coating for thermal humidity resistance.

These failures are preventable. But only if technical specs are matched to end-use conditions.

📌 Add cross-checks into your procurement workflow: verify Tg, softening point, and CTE in your supplier datasheet.

YISHANG supports procurement teams by reviewing application conditions early and helping select materials aligned with field use.

Final Thoughts: Reliable Glass Sourcing Starts with Thermal Understanding

The term “melting point of glass” is misleading. What’s essential is understanding the thermal range over which a glass softens and flows. For procurement teams, this means:

- Checking more than just the max temp rating

- Considering thermal shock resistance and softening behavior

- Confirming compatibility with frame materials and adhesives

📩 Have a project requiring heat-resistant glass for a metal assembly? Talk to the YISHANG team—we’ll help match the right glass for the job.

Frequently Asked Questions

Q1: What is the maximum temperature soda-lime glass can withstand?

A1: Soda-lime glass begins to soften around 730°C. For long-term performance, it’s not recommended above 500°C in sustained use.

Q2: Which glass is best for industrial furnace viewports?

A2: Borosilicate glass is most commonly used due to its mid-cost, high durability, and thermal shock resistance.

Q3: How do I decide between fused silica and borosilicate?

A3: Use fused silica for temperatures above 1200°C or when optical clarity under stress is critical. Borosilicate is more cost-effective for mid-range applications.