Why Dimensional Clarity Drives Smooth Procurement

Dimensional miscommunication is a common—and costly—issue in global metal sourcing. When a spec is interpreted the wrong way—ID instead of OD, or vice versa—it can lead to rejected batches, missed deadlines, and frustrated buyers.

This guide shows how to use diameter specifications to streamline sourcing, clarify RFQs, and avoid the errors that often stem from assumptions. We’ll explore ID vs. OD from the lens of functionality, tolerance, tooling, and industrial application, giving buyers the insight needed to reduce error and increase production certainty.

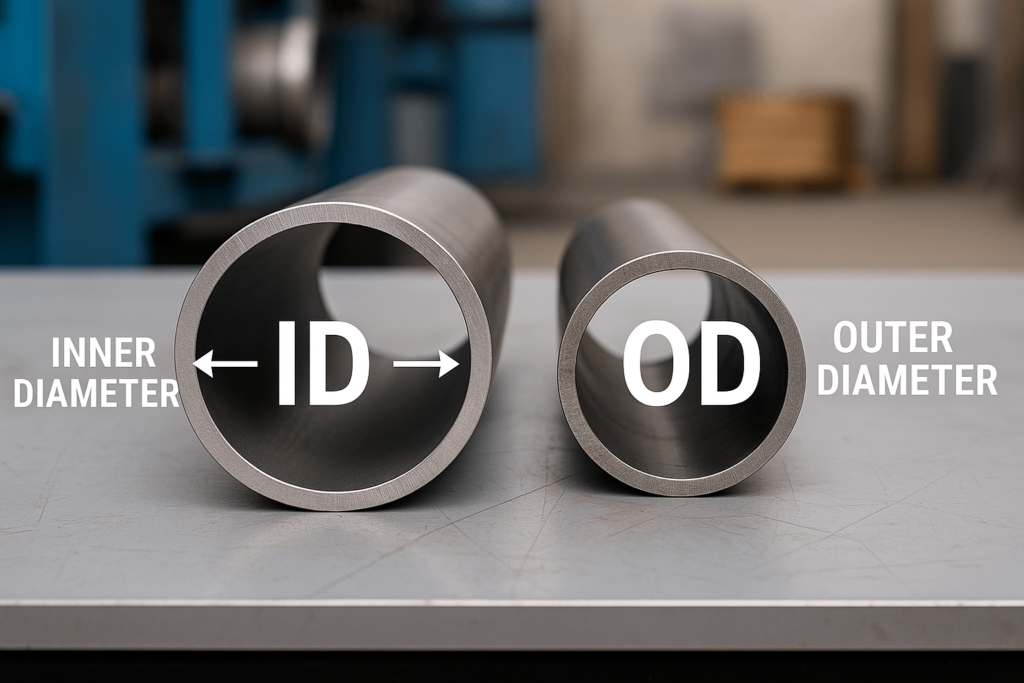

ID vs. OD: What Comes First in Fit

Quick check: Does your part contain something, or does it fit into something?

If it contains—focus on ID.

If it fits in—specify OD.

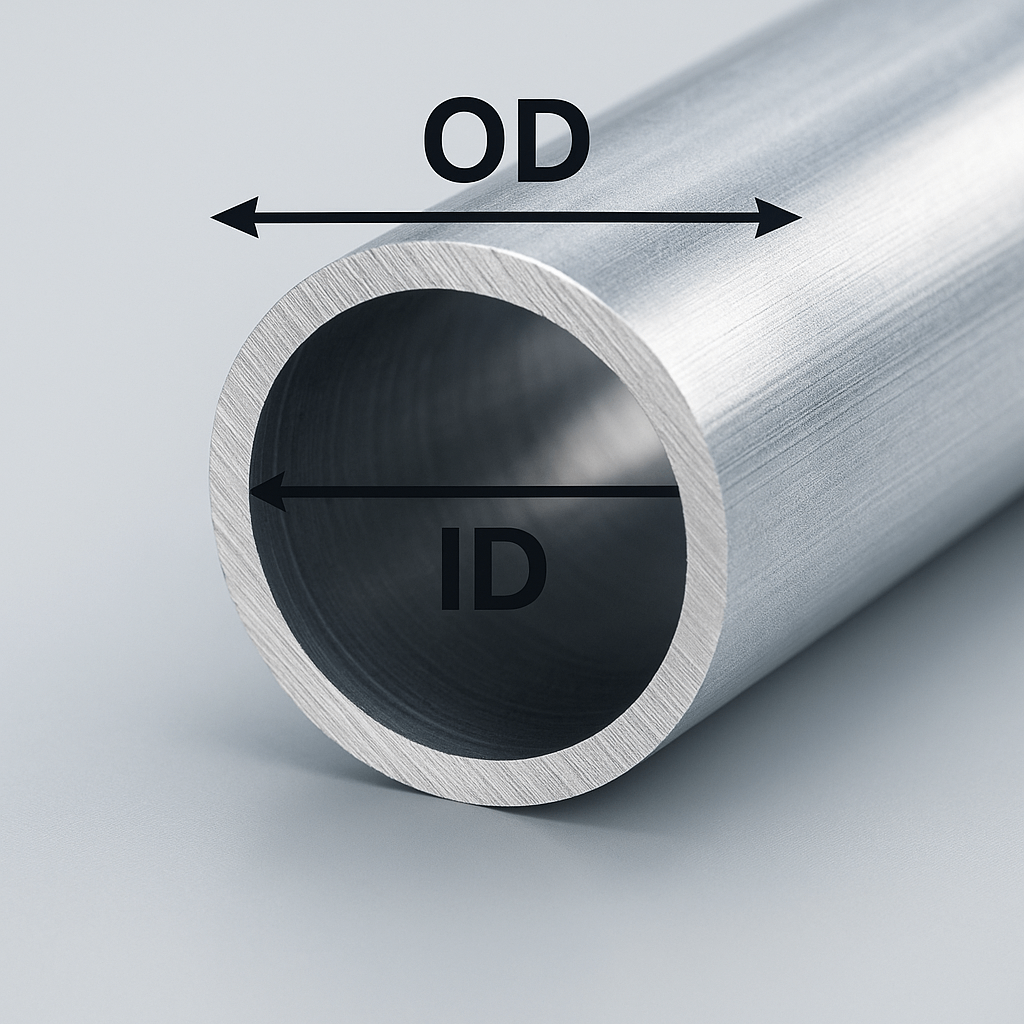

Inner Diameter (ID) determines what your part holds—whether it’s a bearing, airflow, cable sleeve, or press-fit shaft. Outer Diameter (OD) controls how your part mates with external fixtures—like housing cutouts, mounting frames, or structural enclosures.

Misaligned expectations are common. The design may be based on airflow (ID), while a supplier defaults to stock OD. Without clear communication, this leads to 3–5 mm tolerance mismatches, and thousands of unusable units.

Wall thickness becomes a consequence of which dimension you control first. If it’s not called out explicitly, it floats—often creating friction between performance expectations and real tolerances.

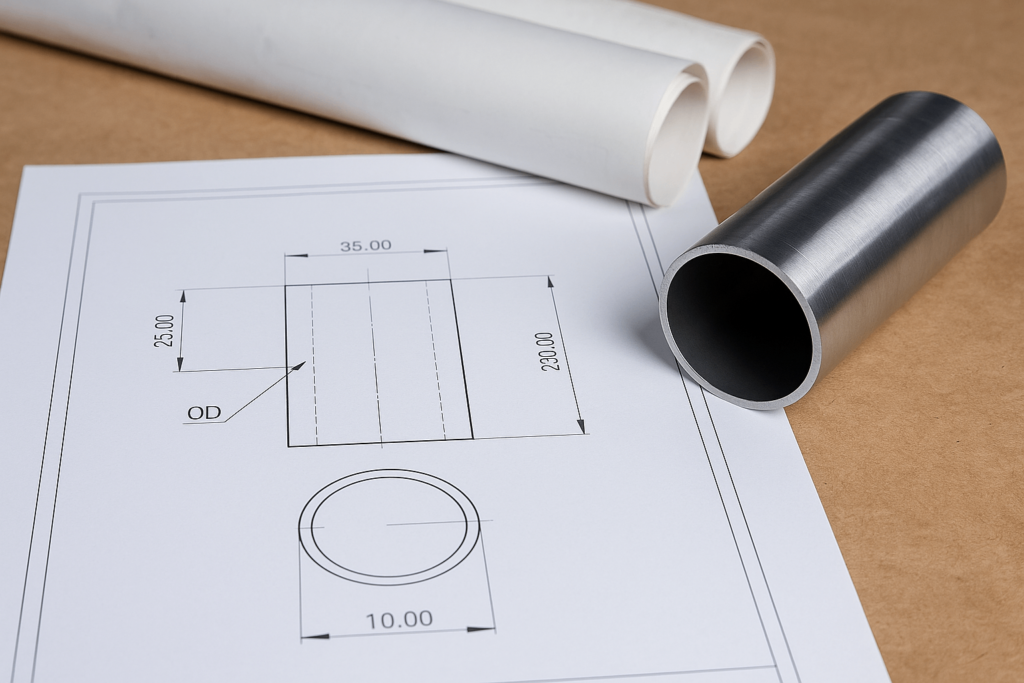

From Drawings to Deliverables: Avoiding Ambiguity

Does your drawing say Ø14—but not whether it’s ID or OD? That’s a risk.

A CAD model is precise, but it’s not always clear to someone unfamiliar with your part’s function. One of the most common causes of pipe ID vs OD confusion is the absence of a functional annotation.

Example from our experience: A drawing listed “Ø22 mm” to accept a motor shaft. The vendor machined to OD instead of ID. Over 3,000 units were scrapped due to assembly failure.

Best practices:

Mark: “Ø22 mm (ID – fits shaft)”

Or: “ID critical – requires H7 tolerance”

If OD matters: “OD fixed – seats into 25 mm cavity”

B2B buyers issuing RFQs across regions must assume the vendor has no context. Precision doesn’t equal understanding.

Tools and Tolerances: Don’t Just Measure—Define

If you don’t define how to measure it, your supplier might guess.

To measure ID, use telescoping gauges or internal micrometers. To measure OD, use calipers or micrometers depending on surface type. When dealing with complex shapes or post-processing variations, 3D scanning or coordinate measuring machines (CMM) ensure consistency.

But the real risk isn’t the tool—it’s tolerance ambiguity.

Say you specify a 30 mm ID, but don’t state the tolerance. One supplier might deliver 29.2 mm; another might grind to 30.1 mm. This leads to press-fit failures, leaks, or rattle.

Add a simple note:

“ID 30 mm ±0.2 mm” or

“OD 25 mm – ISO m6 tolerance”

And define measurement method if critical. For repeat orders, request a go/no-go gauge for verification.

Wall Thickness: Understand the Price You’re Paying

Wall thickness isn’t just a geometry—it’s a cost driver.

Buyers often don’t specify it, assuming the supplier will handle it based on stock. But wall thickness affects:

Material weight and price per unit

Laser-cutting speed and tooling paths

Bending/forming allowances

Thermal or pressure performance

According to standards like ASTM A269 and DIN EN 10220, tolerances vary depending on which dimension is held constant (ID or OD).

If your part must support load or seal pressure, then wall consistency becomes critical. Don’t just let it float—state:

“Maintain 2.5 mm wall ±0.2 mm across ID control”

That sentence alone can save thousands in rework.

Industry Use Cases: ID vs OD by Function

Not every industry prioritizes the same fit logic. This table summarizes which to control first.

| Industry | Control ID | Control OD | Why It Matters |

|---|---|---|---|

| HVAC Ducts | ✅ | ◯ | Airflow clearance = ID |

| Power Housings | ◯ | ✅ | Must fit within casing |

| Medical Tubes | ✅ | ✅ | Internal volume + outer ergonomics |

| Brackets / Frames | ◯ | ✅ | Must align with mount holes |

| Cable Glands | ✅ | ◯ | Must clear cables or grommets |

Pro tip: In battery enclosures and solar mounting frames, OD is often more critical due to structural mating. But for fluid transfer or vapor management, ID governs function.

Common Errors: What Causes Fit Failure?

Four failure patterns we see in global sourcing:

Unlabeled dimensions: “Ø30 mm” with no ID/OD note → wrong assumption.

Conversion errors: Request for 1.5” OD, supplier reads 38 mm ID → 2 mm mismatch.

Material swaps: Steel vs aluminum affects bend radius → wall shifts.

No FAI process: No fit test on first sample → mass rejection.

Each of these stems from vague specs. The fix? Pair numeric values with intent-based descriptions.

Standards to Anchor Your Specs

Global sourcing means global interpretation. Use standards to unify terms.

| Standard | Region | Focus |

| ANSI B36.10 | US | OD-focused for pipes |

| ASTM A270 | US | ID for sanitary tubing |

| DIN EN 10220 | EU | OD with set wall tolerance |

Include these in your RFQ or CAD header. For example:

“Tube per ASTM A269, ID 18 mm ±0.15 mm”

At YISHANG, we validate these standards against our process capability index (Cp/Cpk) during sample approval.

Control What Controls Your Outcome

ID and OD are not neutral—they’re decisions.

The dimension you control governs:

Tooling method

Inspection criteria

Functionality in real-world use

B2B buyers aren’t just ordering specs—they’re managing risk, timeline, and unit cost.

YISHANG helps OEMs and volume purchasers translate dimensional intent into repeatable results.

Have a part that fails on fit? Let’s solve it—starting with the spec.