I. Why Wholesale Buyers Ask This Question

Wholesale buyers move fast. They compare suppliers, evaluate technical language, and judge cost accuracy in minutes. When drawings or RFQs mention

silver solder, the wording often raises a simple but important question:

is silver solder real silver?

Buyers ask this because the phrase influences cost expectations and supplier communication. If it sounds like a precious metal, it may seem expensive. If one supplier lists silver solder and another lists brazing or welding, it creates uncertainty during quotation reviews.

Here is the direct answer many buyers look for:

silver solder is a metal alloy that contains some silver but relies mostly on other metals to control melting and flow. It is engineered for performance, not for precious‑metal value. Misunderstanding this point often leads to confusing internal discussions or mismatched quotes.

Global buyers who work with manufacturers like

YISHANG frequently ask about this topic. Some believe silver solder increases cost; others expect it to provide special strength. This article removes that confusion and offers a clear, practical explanation that supports better sourcing decisions.

II. Why the Term “Silver Solder” Creates Confusion in Global Sourcing

The phrase “silver solder” appears across industries, but each sector uses it differently. Early metalworkers used the name when they added small amounts of silver to tin‑based solder to improve flow. As manufacturing evolved, industries kept the name but changed the formula.

In

electronics, many manufacturers use lead‑free alloys like SAC305, which contain about three percent silver. In

HVAC and plumbing, the term usually refers to high‑temperature brazing alloys that include much higher silver levels. In

jewelry and silversmithing, “silver solder” often describes hard solders designed for joining sterling or fine silver.

This variation creates challenges for overseas buyers. One supplier may use tin‑silver solder for light connections, another may apply silver brazing for structural joints, and a third may avoid the term and list only an alloy code. Prices then vary widely, even when the wording looks similar.

Questions like

“how much silver in silver solder” or

“is silver solder actually silver” usually arise from this inconsistency. Buyers try to match a vague label with a concrete cost, and the term itself offers limited guidance.

III. What Makes Silver Solder “Silver” – A Functional Definition

Understanding Why Silver Is Added

Silver in solder or brazing alloy acts as a performance enhancer. It adjusts melting behavior, improves flow, and supports the formation of stronger intermetallic layers. These traits help manufacturers create clean, reliable joints.

Low‑silver soft solders, typically

1–4% Ag, support electrical and light mechanical joints. Even a small silver addition improves spreading on copper, brass, and plated surfaces. In electronic assemblies, this results in cleaner terminations and better reliability during heat cycles.

Some plumbing and industrial electronics solders contain

less than 2% silver, even when labeled as silver solder. Other variants, such as tin–silver–copper alloys, may include around three percent silver. These differences show why buyers should rely on alloy specifications instead of product names.

High‑Silver Alloys and Their Purpose

At the other end of the spectrum, high‑silver brazing alloys contain

30–56% silver. These alloys flow into tight joints, reduce distortion risk, and generate strong bonds on copper, brass, and some stainless steels.

Jewelry‑grade silver solders may carry

60–80% silver. They melt below the base metal to protect sterling or fine silver components. Even at these high levels, the alloys focus on joining performance rather than precious‑metal content.

Silver appears in these materials because it improves process reliability. Understanding alloy composition helps buyers interpret drawings accurately. “Silver soldered” on a drawing signals a functional decision—not a decorative or luxury upgrade.

IV. So – Is Silver Solder Real Silver?

Fine silver contains 99.9% silver, and sterling silver contains 92.5%. Silver solder contains far less. Its core metals—tin, copper, zinc, and others—shape how it melts and bonds.

Soft solders often contain about 96% tin, 3% silver, and 1% copper. High‑silver brazing alloys may contain around 45% silver with the balance copper and zinc. These materials behave very differently from pure silver and do not carry precious‑metal value.

For buyers, the conclusion is simple:

silver solder contains real silver but is not real silver as a category. Treat it as one joining option among many—similar to welding, brazing without silver, or mechanical fastening.

Understanding this distinction prevents miscommunication, avoids overspecification, and supports clearer quotation comparisons.

V. How Misunderstanding Silver Solder Impacts Procurement

A misunderstanding of silver solder often leads to procurement issues.

The first challenge appears when drawings say “silver soldered” without standards or alloy families. Each supplier interprets it differently. One may choose soft solder; another may choose high‑temperature brazing. Both create acceptable‑looking joints, but their strength and heat tolerance differ dramatically.

Pricing differences follow. A supplier that uses high‑silver brazing alloys factors higher filler costs and longer heating cycles into the quote. A supplier that chooses low‑silver soft solder prices the job much lower. Without clear definitions, comparisons become unreliable.

Another problem arises when buyers assume that more silver guarantees better performance. Joint strength depends on clearance, heating consistency, preparation, and design—not just silver content. A well‑executed moderate‑silver joint can outperform a poorly prepared high‑silver joint.

A final challenge appears during internal discussions. When teams believe silver adds inherent value, they request silver solder in applications where welding or mechanical fastening works better. This increases cost and complicates production. Clear understanding keeps decisions focused on performance and compliance.

VI. How Professionals Evaluate Silver Solder in Real Projects

Step 1: Matching the Alloy to Base Metals

Experienced engineers start by examining base metals. Stainless steel, galvanized steel, aluminum, copper, and brass all respond differently to heat. Silver‑bearing alloys bond well with copper and brass, moderately with some stainless steels, and poorly with many aluminum alloys.

Asking suppliers which metals they plan to join—and why they selected a specific alloy—reveals the depth of their process knowledge.

Step 2: Evaluating the Service Environment

Teams then consider operating temperature, vibration, cycling, mechanical loads, and corrosion exposure. Silver solder performs well in fluid‑carrying connections, electrical interfaces, and tightly aligned parts. It is less suitable for primary structural connections under heavy stress.

A supplier who can explain long‑term joint behavior demonstrates strong engineering capability.

Step 3: Ensuring Manufacturability and Repeatability

Manufacturers also evaluate production consistency. A joining method that works during prototyping may fail during large‑scale runs if it requires delicate manual control or extensive cleaning.

Cycle time, operator training, fixturing, and compatibility with finishing processes—such as powder coating or plating—shape method selection. Suppliers who explain these details usually maintain stronger process control.

Regulatory requirements influence these choices as well. Regions that restrict lead push manufacturers toward lead‑free, silver‑bearing alloys. Buyers should confirm RoHS compliance or drinking‑water safety when relevant.

VII. The Real Role of Silver Solder in Metal Manufacturing

Where Silver Solder Is Typically Used

Manufacturers rely on silver solder when precision and clean flow matter more than structural strength. Buyers often see it in copper tubing joints for vending machines, brass fittings in enclosures, sensor housings, and electrical interfaces.

These areas need reliable sealing, conductivity, or corrosion resistance, and welding may distort or damage the parts.

Where Silver Solder Is Not Appropriate

Silver solder does not suit frames, brackets, beams, or shock‑loaded components. Those parts require welding or mechanical fastening. When suppliers claim that an entire frame is silver soldered, buyers should request clarification.

Understanding Alloy Differences

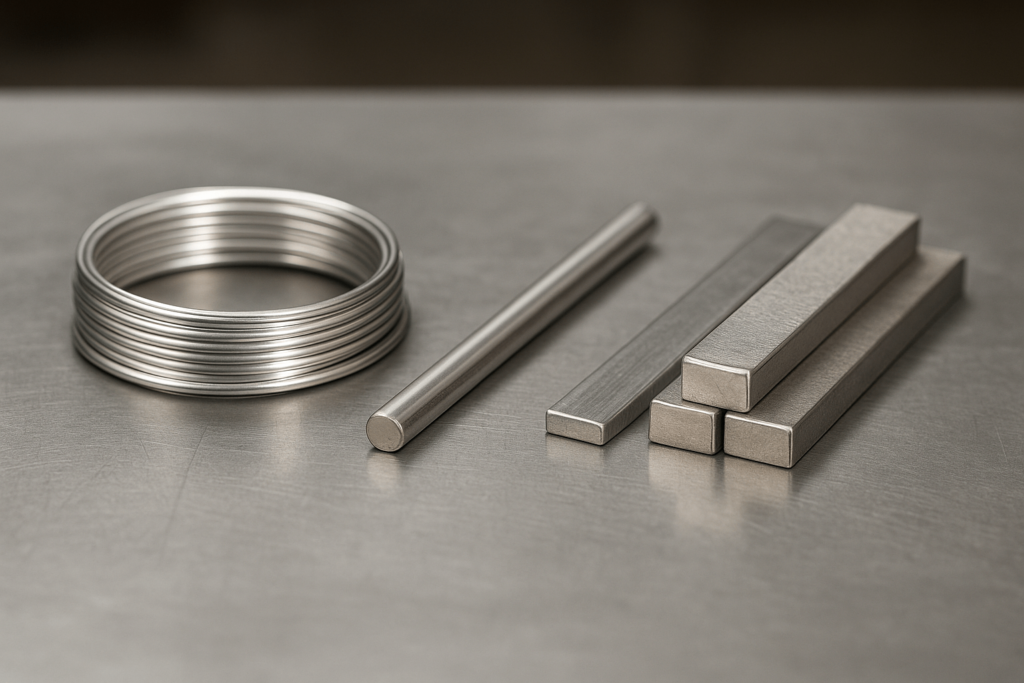

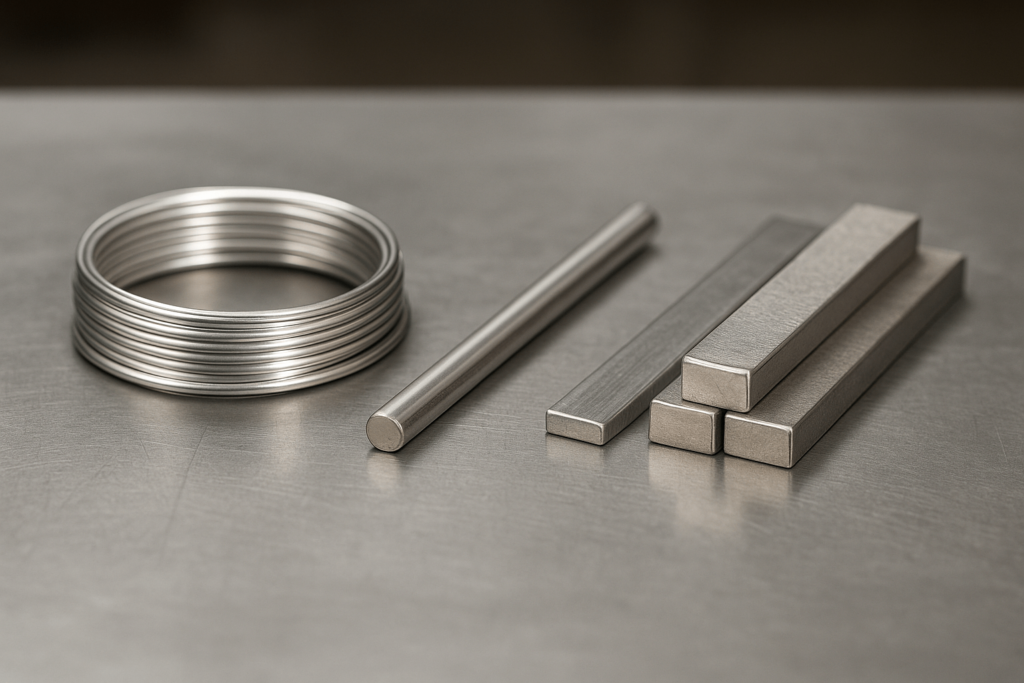

| Joining Material Type |

Ag % Range |

Joining Method |

Melting Range °C |

Typical Use Case |

| Silver‑bearing soft solder |

1–4% |

Soldering |

215–230 |

Electrical joints, light fixes |

| Medium‑silver brazing alloy |

25–40% |

Brazing |

620–750 |

Copper–brass, copper–steel fittings |

| High‑silver brazing alloy |

40–56% |

Brazing |

620–800 |

High‑reliability valves, precision parts |

| Sterling silver |

92.5% |

Base material |

890–910 |

Jewelry, decorative work |

| Fine silver |

99.9% |

Base material |

960–962 |

High‑purity silver products |

What “Silver Soldered” Means on Silverware

Some products, such as hotelware or antique teapots, carry “silver soldered” stamps. In these cases, manufacturers used silver‑based solder to join parts on silver‑plated or coin‑silver bases. The stamp advertised durability, not purity.

For industrial buyers, this historic use reinforces a key point: the stamp describes

how parts were joined, not the silver content of the metal.

VIII. What Buyers Should Ask Instead of “Is Silver Solder Real Silver?”

Buyers gain more clarity when they focus on suitability rather than purity. Helpful questions include:

- What role does the joint play—sealing, conductivity, alignment, or structure?

- Which metals are involved, and why was this alloy chosen instead of welding or standard solder?

- What temperatures, loads, or corrosion conditions will the part face?

- How will the joint interact with coating, plating, or galvanizing?

- Are lower‑cost joining methods available without sacrificing performance or compliance?

Suppliers who explain when

not to use silver solder often demonstrate stronger technical maturity. This insight reduces risk for high‑volume or long‑term programs.

IX. FAQ for Wholesale Buyers

Q: How much silver is in silver solder?

Soft solders usually include 1–4% silver. Plumbing solders may include less than 2%. High‑silver brazing alloys contain 30–56%, and jewelry‑grade versions may reach 80%, depending on the specific application.

Q: What is silver solder made of?

Most silver solder blends combine silver with tin, copper, zinc, and sometimes trace elements. The exact mix depends on whether the alloy supports low‑temperature soldering or high‑temperature brazing. Technical data sheets list these compositions, and buyers should request them when comparing suppliers.

Q: What does “silver soldered” mean on a metal product?

In industrial fabrication, “silver soldered” usually means the manufacturer joined the parts with a silver‑bearing solder or brazing alloy rather than a plain tin or tin‑lead solder. On silverware and hollowware, the phrase often indicates that handles, bases, or spouts were assembled using durable hard solder on a plated or silver base. In both cases, the term describes the joining method, not the metal’s purity.

Q: Is silver solder real silver?

Silver solder contains real silver but does not qualify as real silver in the sense of high‑purity sterling or fine silver. It is best understood as a functional joining alloy. For sourcing decisions, it makes more sense to evaluate whether the alloy and process meet your performance, compliance, and cost targets.

X. Conclusion: A Clear, Buyer‑Focused Understanding

Silver solder depends on silver to deliver controlled melting, reliable flow, and strong joints, but it does not belong in the same category as precious silver products. It is an engineered joining material that competes with other options such as brazing without silver, welding, and mechanical fastening.

For wholesale buyers, treating silver solder as a technical choice rather than a luxury feature leads to better specifications, clear RFQs, and more accurate cost comparisons. When you read “silver soldered” in a drawing or capability list from a supplier like

YISHANG, the key questions are about base metals, service environment, compliance, and process control.

If you are evaluating metal products that may involve silver solder, or weighing different joining methods for a new project, you can bring the ideas in this guide into your next supplier conversation. A short technical discussion at the start of a project often prevents longer, more costly discussions later. And if you need a manufacturing partner who can talk through these trade‑offs in clear, practical terms,

YISHANG is ready to support your decision‑making with transparent information and application‑oriented advice.