Opening the Cut: Why Kerf Deserves Its Own Conversation

In procurement, precision isn’t optional—it’s expected. And among the many variables influencing fit and tolerance, cut width often flies under the radar.

So, what is cut width? It’s the width of material removed during cutting. Small as it is, it has big consequences for batch consistency and part performance.

If cut width is ignored or miscalculated, you risk rework, part failure, and missed deadlines. For high-volume metal fabrication, that’s unacceptable.

YISHANG integrates kerf control from the earliest design stage to ensure dimensional accuracy and predictable fit for bulk orders.. Here’s why that makes a difference.

Stainless steel is a versatile material, but not all types perform the same in real-world environments. For wholesale buyers sourcing custom parts, the wrong material choice can result in surface degradation, premature failure, and inflated warranty claims.

At YISHANG, we’ve helped global buyers across 50+ countries minimize risk by choosing the right stainless steel for specific environments, industries, and cost structures. We are certified by ISO 9001 and RoHS, ensuring sourcing traceability across international markets. All materials comply with major international standards such as ASTM, EN, and JIS.

This guide is not just about grades—it’s about procurement logic, practical application, and decision-making efficiency.

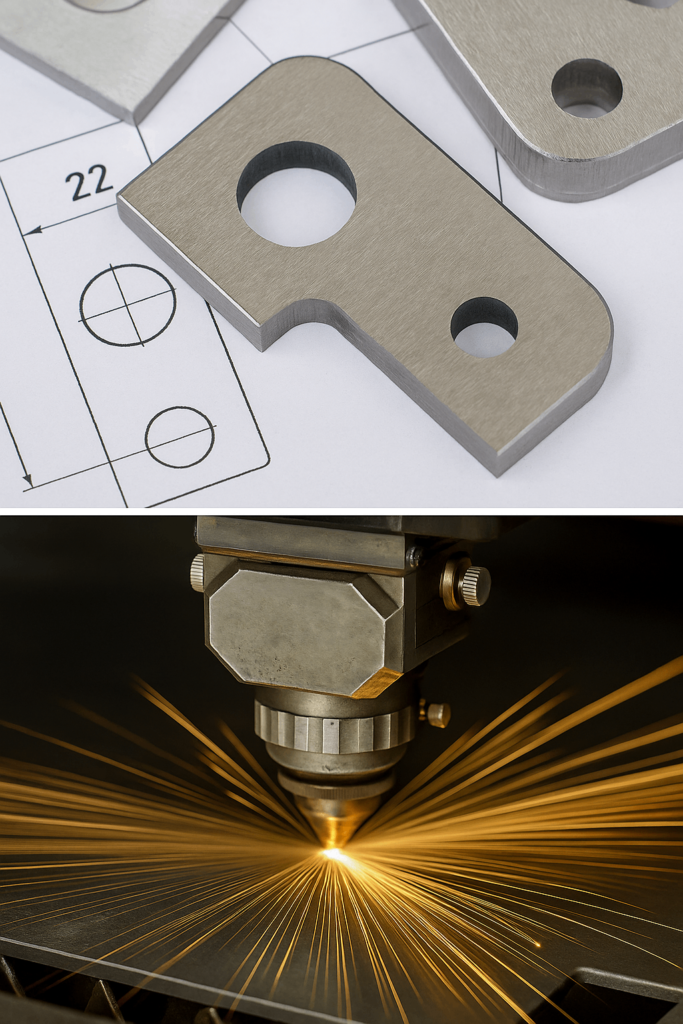

Kerf as a Design Variable, Not Just a Physical Gap

Kerf isn’t fixed. It varies based on material, tool diameter, cutting force, and machine condition—especially in sheet metal fabrication.

Yet many CAD drawings assume it’s constant—or worse, don’t consider it at all.

A 0.1 mm error sounds small, but across a structure of 10+ components, it can cause real issues: panel gaps, poor alignment, or frame distortion.

That’s why suppliers should calculate cut width into every cut. Adjusting offsets before fabrication means tighter tolerances and fewer problems later.

For B2B buyers, this translates to fewer returns, faster assembly, and better project outcomes.

What Affects Cut Width? (In Laser Cutting and Beyond)

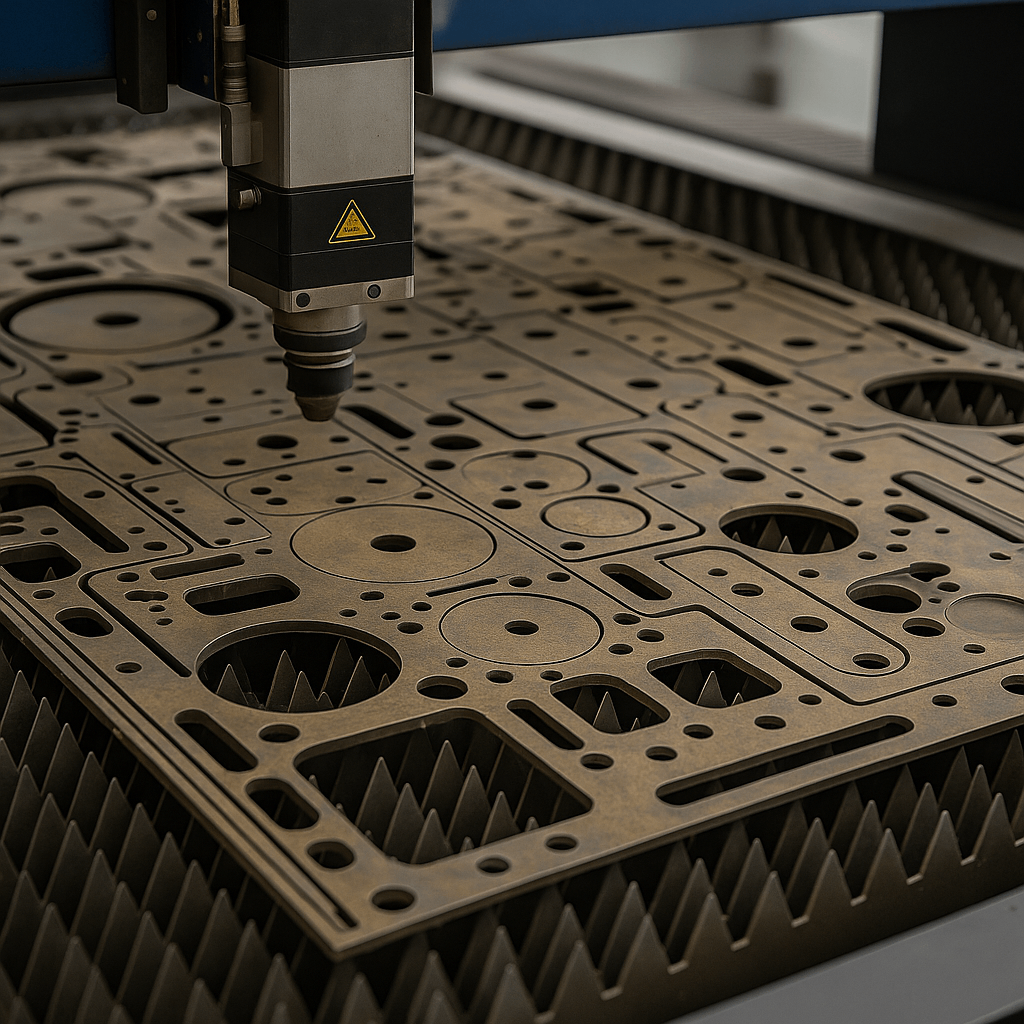

Kerf formation is shaped by several variables—including machine mechanics, cutting speed, and material behavior. Understanding what affects cut width size is essential for maintaining dimensional accuracy, especially in laser cutting.

In laser cutting, beam diameter, speed, gas pressure, and focus influence cut width size. In CNC milling, tool sharpness and feed rate are critical. For waterjet systems, pressure and nozzle standoff matter.

Real-world example: a fiber laser cutting 1 mm stainless steel typically yields a cut width between 0.10 mm and 0.15 mm. Misalignment can push this up to 0.25 mm, enough to ruin a press-fit or slot design.

Suppliers that calibrate equipment per job and validate with test cuts offer a higher degree of consistency—and fewer surprises for procurement.

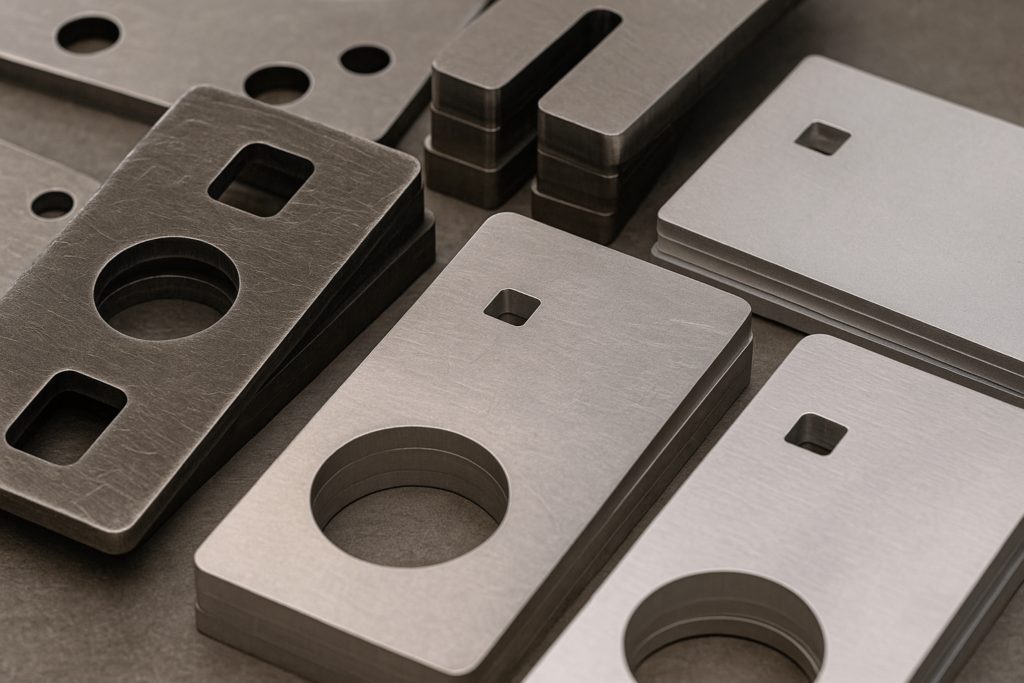

Why Kerf Precision Matters in Every Component

Kerf tolerance issues aren’t isolated. They build cumulatively across multiple cuts and components. This cumulative effect is often referred to as kerf tolerance, and managing it is essential in high-precision applications.

Even a 0.1 mm deviation repeated across 10 components creates a 1 mm offset. In display units, kiosks, or structural frames, that may mean doors don’t align, panels won’t sit flush, or welding gaps widen.

Poor kerf control increases your reliance on rework, leading to higher labor costs, shipping delays, and missed installation schedules.

On the flip side, cut width-aware fabrication improves yield. With precise nesting strategies, more usable parts fit per sheet—saving on materials and cost per unit.

Why CAM Defaults Miss Real-World Cutting Precision

Most CAM platforms allow you to set cut width offsets—but default settings don’t account for real-world variation. That’s where the risk lies.

Tool wear, machine age, heat distortion, and even material lot changes all shift the cut width slightly. For example, on identical CO2 lasers, cut width on aluminum might differ from 0.15 mm to 0.28 mm across batches.

CAM can assist with consistency, but procurement teams should confirm that suppliers actively measure and adjust cut width during production. Relying solely on software settings is risky in batch fabrication.

Cut Width by Material and Method

Different materials behave differently under the same tool.

Use the table below to understand general cut width expectations:

| Material | Cutting Method | Typical Kerf Width (mm) |

|---|---|---|

| Stainless Steel | Fiber Laser | 0.10 – 0.15 |

| Aluminum | CO2 Laser | 0.15 – 0.25 |

| Mild Steel | Plasma | 0.80 – 1.20 |

| Acrylic | CO2 Laser | 0.20 – 0.30 |

| Wood (Plywood) | CNC Router | 1.50 – 3.00 |

Ask your supplier if they recalibrate cut width when switching materials. If not, tolerance errors are likely to follow.

Offset Calculators: Simplifying the Math Behind Cut Width

Precision manufacturing depends on more than machines. It requires math.

Kerf offset—the intentional adjustment of toolpath to account for material loss—ensures parts fit together with minimal deviation. It becomes especially important in tight-tolerance parts or mating designs.

Formula: Adjusted Toolpath = Nominal Dimension ± (Kerf / 2)

To make this process more accessible, some manufacturers provide a kerf calculator or kerf offset calculator. These tools help procurement teams, engineers, and designers quickly validate whether dimensions will hold during production.

While the math seems minor, missing it can cascade into large deviations across an assembly. Experienced vendors use both CAM programming and physical verification to close that gap.

What Goes Wrong Without Proper Cut Width

Let’s look at three real-world failures:

Case A: 300 display racks were rejected due to welded joints not seating properly. Kerf drift was the cause. Losses exceeded $5,800.

Case B: CNC-cut slots for control plates were 0.2 mm too narrow. All 200 units needed manual rework, delaying delivery by two days.

Case C: Powder-coated panels warped post-treatment. Kerf-induced thermal distortion hadn’t been anticipated during design.

Each failure could have been prevented with proactive cut width management—saving time, reducing scrap, and preserving client trust.

Material Efficiency Through Better Cut Planning

Procurement doesn’t just manage cost—it manages efficiency.

By optimizing cut width width from 0.22 mm to 0.17 mm, one project saw a 6% increase in parts per sheet. That translated to more than $4,000 saved in raw materials over three months.

Better kerf control also reduces scrap, lowers rework rates, and aligns with ESG goals.

Ask These 3 Cut Precision Questions Before Sourcing

How do you define and control cut width across different materials and machines?

Do you measure cut width per project and integrate results into your CAD/CAM workflow?

Can you show examples where kerf control improved part quality or material use?

If a supplier can’t answer confidently, they may not be ready for your scale.

At YISHANG, we know that procurement success depends on production accuracy. Kerf is one of those small details with large consequences.

Looking for a partner who knows what is cut width and manages it with precision?