Why Lightness Matters in B2B Procurement

In global OEM/ODM sourcing, metal weight affects far more than shipment cost—it influences durability, fuel efficiency, and ease of installation. Whether it’s display fixtures, vending enclosures, or lightweight metal frames, reduced weight leads to better handling and downstream performance.

Procurement managers across Europe and North America increasingly turn to lightweight metals like aluminum and magnesium to optimize part design, meet transportation standards, and reduce lifecycle energy costs.Understanding what is the lightest metal—and more importantly, which metals are structurally viable and scalable—is key to procurement success. Buyers often ask: what is the lightest metal in the world? The scientific answer is lithium, but in industry the lightest structural metals used are magnesium and aluminum. This guide directly answers what is the lightest metal (Lithium) and compares the lightest metals such as magnesium, aluminum, and titanium for industrial buyers.

What Is Light Metal, and Why It’s More Than Just Density

Light metals are metallic elements with relatively low densities—under 5 g/cm³. However, in real-world procurement, low weight alone is not a sufficient metric. Factors like corrosion resistance, machining behavior, coating adaptability, and recyclability heavily influence sourcing decisions.

Magnesium is lighter than aluminum, but without protective coatings, it may corrode in humid climates. Titanium is durable and corrosion-resistant, yet too expensive and slow to machine for many commercial applications.

Materials like aluminum 6061 and AZ91D magnesium provide the right balance: lightweight, formable, recyclable, and compatible with standard finishing workflows such as anodizing or powder coating.

Emerging solutions like microlattice metals are promising but not yet suitable for mass-market production. These remain cost-restrictive and are discussed further in Section 9. Among all light metals, magnesium is considered the lightest strong metal suitable for real-world structural use, while aluminum balances weight with corrosion resistance.

What Are the Lightest Metals?

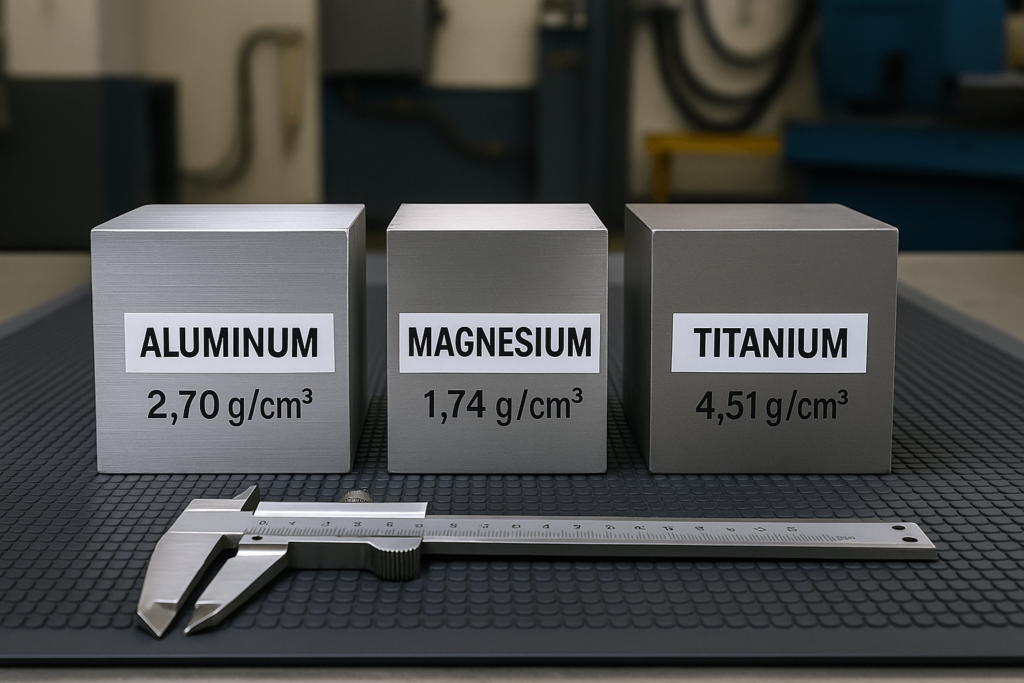

The lightest metals include:

Lithium (0.534 g/cm³) – the absolute lightest elemental metal, but too reactive for structural parts.

Magnesium (1.74 g/cm³) – the lightest structural metal, strong and formable.

Aluminum (2.70 g/cm³) – slightly heavier but excellent corrosion resistance and scalable use.

Titanium (4.51 g/cm³) – durable, corrosion-resistant, but costly and harder to machine.

Beryllium (1.85 g/cm³) – very light but toxic, restricted in most industries.

These lightest metals vary by practicality: magnesium and aluminum are the most commercially viable, while lithium remains essential in batteries but not for structures.

What Is the Lightest Metal in the World?

Lithium, with a density of 0.534 g/cm³, is the absolute lightest metal in the world. However, due to its extreme reactivity, low mechanical strength, and flammability, it cannot serve as a structural material. Instead, magnesium (1.74 g/cm³) is recognized as the lightest structural metal and is widely used in industry for frames, brackets, and enclosures. This makes magnesium the practical answer when buyers ask: what is the lightest metal used in industry?

Is Lithium the Lightest Metal—and Can You Use It?

Lithium, with a density of 0.534 g/cm³, is the lightest elemental metal. It’s essential in battery production and energy storage systems. However, its high reactivity, low structural integrity, and flammability make it unsuitable for components that bear load or require shaping.

For structural and fabricated sheet metal applications, magnesium and aluminum offer the best trade-offs between strength, weight, cost, and export-readiness. Their compatibility with ISO and RoHS standards also simplifies customs clearance and international compliance—as the table below will further illustrate.

Magnesium: The Practical Choice for Lightweight Structural Components

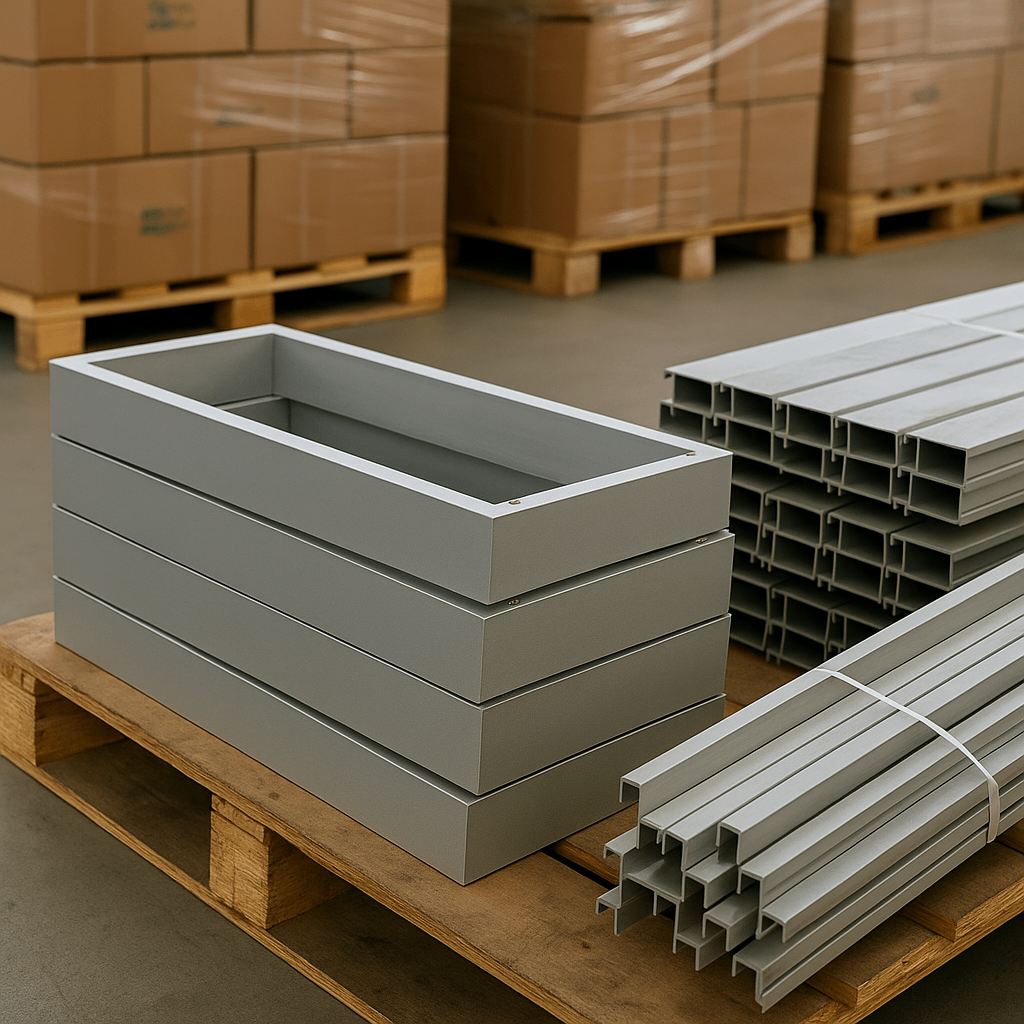

Magnesium, with a density of just 1.74 g/cm³, is the lightest structural metal used in manufacturing. Alloys like AZ91D and AM60 provide strength, machinability, and exceptional formability for custom-built structures and parts.They offer strength, machinability, and exceptional formability for custom-built structures and parts.

When used in signage frames, vending units, or modular fixtures, magnesium lowers weight without compromising rigidity. Its high strength-to-weight ratio is particularly beneficial for products requiring ease of movement, such as foldable or mobile units.

Treated with e-coating, PVD, or micro-arc oxidation, magnesium meets global corrosion standards. Vendors like YISHANG deliver RoHS-compliant magnesium parts suitable for long-haul shipping and warehouse stability.

Comparing Structural Light Metals for Procurement Decisions

To support informed sourcing, here’s a practical comparison of key light metals:

| Metal/Material | Density (g/cm³) | Common Applications | Formability | Corrosion Resistance | Scalable for Volume Production |

|---|---|---|---|---|---|

| Lithium | 0.534 | Batteries, energy storage | Poor | Very low | ❌ |

| Magnesium (AZ91/AM60) | 1.74 | Display units, vending, automation frames | Excellent | Moderate (coated) | ✅ |

| Aluminum (6061/5052) | 2.70 | Structural panels, electronics casings | Excellent | High | ✅ |

| Titanium (Grade 2/5) | 4.51 | Aerospace, implants, marine parts | Good | Excellent | ⚠ High-cost |

Magnesium and aluminum remain the most commercially viable materials due to their formability, corrosion control options, and scalable processing. They are commonly used in recyclable, high-volume production environments and work well with MIG welding, CNC cutting, and coating technologies. For buyers comparing the lightest metals for industrial use, magnesium and aluminum remain the most scalable, while lithium is reserved for batteries.

Applications That Benefit Most from Lightweight Metals

Light metals serve different purposes depending on structural roles, weight goals, and environmental stressors.

Aluminum is widely chosen for electronics casings due to its strength and excellent thermal conductivity. Magnesium is used where lightweight framing or structural rigidity is key—like collapsible displays, EV brackets, or signage frames.

In fact, YISHANG helped a Dutch OEM reduce component weight by 18% using AZ91D magnesium, resulting in lower shipping costs and improved product handling.

Hybrid aluminum-magnesium setups are ideal for modular systems in transportation, automation, and infrastructure. Light metals also reduce fatigue loads in warehouse frames and freestanding enclosures.

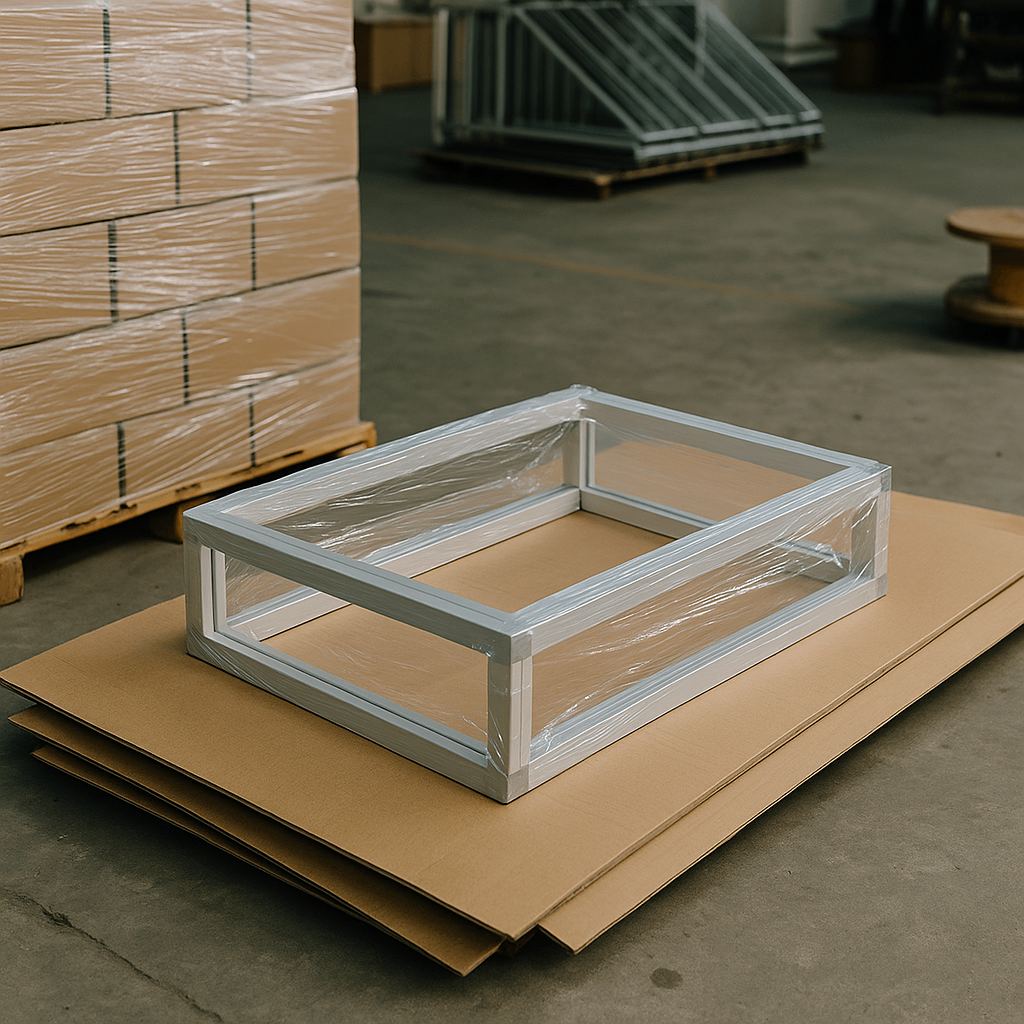

Real Sourcing Considerations: Surface, Welding, Certification

The lightest metal isn’t always the most production-friendly. Magnesium often requires inert gas welding and must be coated properly for marine or humid zones. Aluminum, on the other hand, welds well using MIG/TIG methods and anodizes uniformly.

Sourcing managers should prioritize suppliers that comply with international certifications like REACH, RoHS, ISO 9001, and ISO 16220. This ensures smoother customs processing, lower failure risk, and a clear material traceability chain.

YISHANG provides full surface treatment consultation, adhesion testing, and inspection reports—critical for wholesale clients sourcing precision-cut, ready-to-ship structural light metals.

Lightweight Doesn’t Always Mean Better

Light metal selection isn’t just about grams per cubic centimeter. Titanium offers excellent resistance and strength, but at 5–10x the machining cost of aluminum. Beryllium is extremely light but highly toxic and restricted in most industrial markets.

In many cases, hybrid structures—like aluminum beams with stainless steel joints—optimize mechanical performance without overextending budget or production timelines.

Formability, lifecycle cost, and compliance matter just as much as low weight—especially in large-volume international orders.

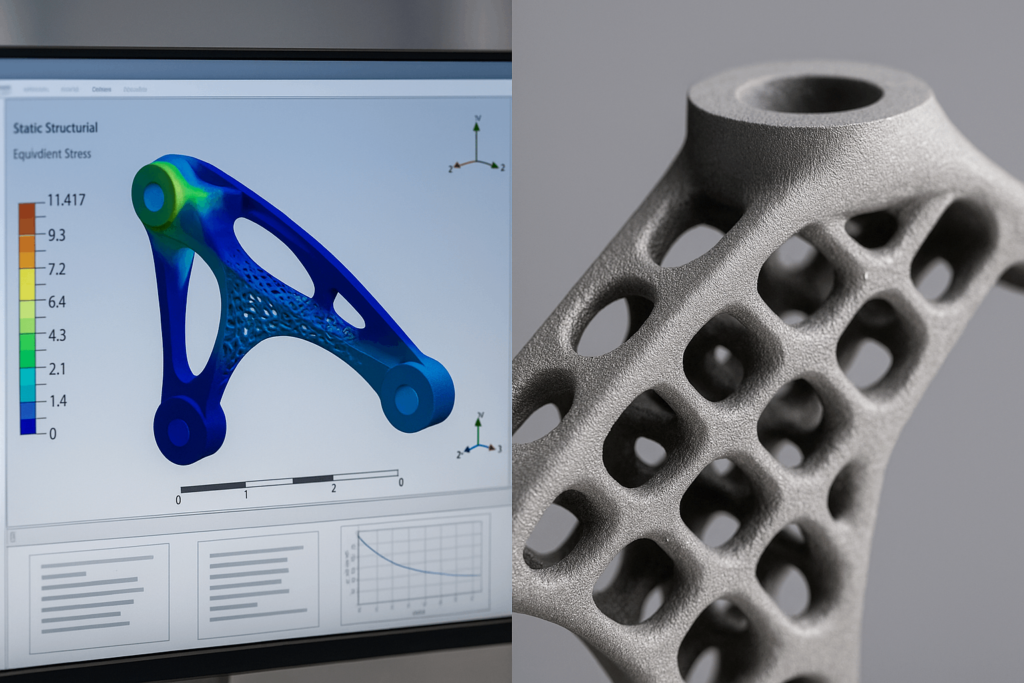

Future Outlook: Smarter Alloys and Predictive Design

Buyers are turning to digital simulation to predict alloy performance, validate lifespans, and reduce physical prototyping cycles. AI-driven material modeling is increasingly embedded in early-stage RFQs.

Microlattice and other 3D-printed metal frameworks remain exciting but commercially limited due to production expense and complexity. They are currently used in high-budget aerospace and biomedical sectors.

Looking ahead, buyers will increasingly request ISO 14001 certifications, environmental traceability, and energy-efficient material options. Vendors like YISHANG support these ESG-forward models with documented sustainability chains and lifecycle reporting.

Conclusion: What Is the Lightest Metal, and Which Lightest Metals Are Best for Industry

The lightest metal in the world is lithium, but for real-world sourcing, magnesium and aluminum are the most practical lightest metals for manufacturing. In other words, lithium answers the question of what is the lightest metal in the world, but magnesium is the lightest strong metal you can reliably source for industry. For most OEM buyers, aluminum and magnesium represent the best trade-off between weight, durability, and compliance. Understanding what is the lightest metal helps narrow down sourcing options—but optimal decisions require a broader view.

For most commercial manufacturing needs, magnesium and aluminum deliver the best value: lightweight, compliant, processable, and scalable. Their widespread acceptance in structural use makes them the go-to materials for global OEM procurement.

Looking to source light metals that meet both regulatory and performance standards? A qualified supplier like YISHANG can help streamline your procurement process.