If you buy metal parts at wholesale volumes, you already know the uncomfortable truth: a beautiful prototype can still lead to a painful production ramp. The prototype may meet the drawing, pass a quick fit check, and even look “ready,” yet the first bulk order arrives with variation, rework, or shifting lead times.

That is why many sourcing teams evaluate metal prototyping services less as “sample making” and more as an early supplier qualification step. The goal is to reduce the risk of inconsistent batches, unexpected tooling changes, and cost drift once volume production begins.

This article is written for overseas wholesale buyers, sourcing managers, and engineering teams who work together on custom metal products. It explains how to interpret prototypes so they reflect production reality, how to spot hidden manufacturing assumptions, and how to use prototyping to support confident purchasing decisions.

What a Metal Prototype Is Meant to Validate—and What It Is Not

Wholesale buyers rarely fail because they cannot read a drawing. They fail when a prototype answers the wrong question. A prototype can be technically correct and still be commercially misleading if it does not validate the risks that matter in ongoing supply.

A metal prototype should validate a specific uncertainty: performance, manufacturability, or cost behavior. Problems start when one prototype is expected to validate everything at once. The supplier delivers a single “golden sample,” and the buyer is asked to treat it as proof that mass production will be straightforward.

In practice, prototypes are not miniature production runs. They are controlled tests of assumptions. A functional prototype may confirm strength or heat resistance, but that does not guarantee that the part can be produced repeatedly with the same result. A polished prototype may look production-ready while revealing little about fixture strategy, welding distortion control, or tolerance stack-up in assemblies.

From a buyer’s point of view, the most useful prototypes are those that make manufacturing behavior visible. That is why experienced procurement teams often ask questions that sound less like product design and more like process control: “What will vary in production?” “What is the repeatable tolerance capability?” “Where will rework occur if variation shows up?”

Validation vs. Demonstration: A Practical Buyer Lens

A helpful way to prevent misalignment is to treat each prototype as either a validation prototype or a demonstration prototype. Demonstration prototypes support internal approvals and visual alignment. Validation prototypes support purchasing decisions because they are designed to expose production constraints.

For many wholesale programs, the highest ROI comes from validation. It provides evidence about repeatability, inspection approach, and process maturity—factors that determine whether supply remains stable after the first shipment.

The First Decision That Determines the Value of Any Prototyping Effort

Before you decide whether to use CNC machining or sheet metal forming, a more important decision needs to be made: what risk are you trying to reduce right now? This question sets the entire direction of the prototyping effort.

In some projects, buyers need to confirm technical feasibility. Can the part exist within the constraints of metal fabrication? Are there features that will crack during forming, distort during welding, or exceed realistic tolerance capability? In other projects, manufacturing feasibility is the core concern. Can the supplier make the same part again and again, at the planned throughput, without drifting out of spec?

For long-term wholesale programs, economic feasibility often becomes the deciding factor. Small design choices can impact tooling, cycle time, scrap rate, and inspection cost. When those costs move, your landed cost and margin move with them.

When intent is unclear, prototypes tend to answer the wrong question. A high-precision CNC sample might look impressive but offer limited insight into prototype sheet metal parts or sheet metal prototype fabrication that will be used in actual production. Conversely, a quick fabricated sample may reveal assembly issues but underrepresent final tolerance expectations.

A Buyer-Friendly Evidence Map

The fastest way to align expectations is to tie prototype evidence to a specific decision.

| Prototype goal (what you need to decide) | What evidence matters most | Buyer-facing question it answers |

|---|---|---|

| Technical feasibility | Deformation, cracking, interference, thermal behavior | “Will this design physically work in metal?” |

| Manufacturing feasibility | Repeatability across multiple pieces, fixturing logic, distortion control | “Can this supplier make it consistently?” |

| Economic feasibility | Cycle time drivers, yield risk, inspection effort, finishing constraints | “Will cost stay stable at volume?” |

This approach keeps prototyping focused. It also helps buyers avoid approving a supplier based on a single “good-looking” unit that does not represent production conditions.

Speed in Metal Prototyping: When It Creates Value—and When It Conceals Risk

Fast turnaround is often marketed as the main advantage of modern prototyping. For wholesale buyers working under tight timelines, speed can be valuable—but only if it creates clarity. Speed does not automatically reduce sourcing risk.

Rapid iterations are most useful early, when design assumptions are still fluid. Rapid sheet metal samples can quickly expose obvious issues such as insufficient stiffness, impractical bend geometry, poor access for assembly, or clearance conflicts in a cabinet or enclosure. When the goal is learning, speed helps eliminate weak concepts before additional resources are invested.

Problems emerge when speed replaces manufacturing realism. Quick prototypes are often produced with simplified methods, extra manual attention, or non-representative tolerances. A rapidly machined prototype may ignore grain direction and residual stress. A hand-fitted prototype may hide assembly sensitivity that will become costly during bulk production.

From a procurement perspective, the key question is not “How fast can we get a sample?” but “How quickly can we reduce uncertainty?” A fast prototype that hides production risk can delay the real learning until after you commit to volume.

Lead Time Should Be Paired With Repeatability Signals

Speed is easy to advertise. Repeatability is harder to prove. For wholesale procurement, it helps to evaluate lead time alongside signals that the supplier is thinking in production terms.

When discussing timing for prototype sheet metal parts or machined samples, ask how the supplier will reduce variation and confirm critical features early. The answer does not need to be complicated, but it should be specific.

Here are a few practical signals that usually correlate with smoother scale-up:

- Multiple units can be produced in the same run for comparison, not just a single hand-fitted piece.

- Inspection criteria are defined early for critical-to-quality features, with a clear method for measurement.

- Process variation is openly discussed, including where it may show up and how it will be controlled.

A supplier who can move quickly and communicate how production variation will be controlled is usually a safer long-term partner.

What Wholesale Buyers Should Include in a Prototype RFQ

Many delays in sheet metal prototype fabrication and CNC prototyping are not caused by machining time, but by missing information. The fastest projects are typically the ones where the buyer provides the details that affect production stability.

If you want prototyping to predict production—not just produce a sample—your RFQ should clarify the “why” behind the prototype. State whether the goal is feasibility, repeatability, or cost stability. This allows the supplier to choose methods that mimic production constraints instead of delivering a visually perfect one-off.

In practical terms, include a 3D model when available, a 2D drawing that highlights critical features, and a clear note on the target quantity range for production. If there are functional surfaces, define the measurement approach you expect (for example, flatness on a mounting plane, hole position relative to datum features, or assembly clearance requirements). When finish matters, specify whether the finish is for appearance approval or corrosion protection, because those are very different choices.

This is not about paperwork. It is about giving your metal prototyping services partner the context needed to build prototypes that translate into stable bulk orders.

The Manufacturing Assumptions Hidden Inside Most Metal Prototypes

Every prototype contains assumptions about how the part will be manufactured at scale. Those assumptions are often invisible during a one-off build, yet they dominate quality and delivery outcomes once production volume increases.

Common assumptions hide in bend sequencing, welding order, fixture access, and assembly logic. A prototype may be fabricated with extra care, additional tack welds, or manual correction that will not be economically feasible in production. If those realities are not surfaced early, buyers may approve a sample that cannot be repeated reliably.

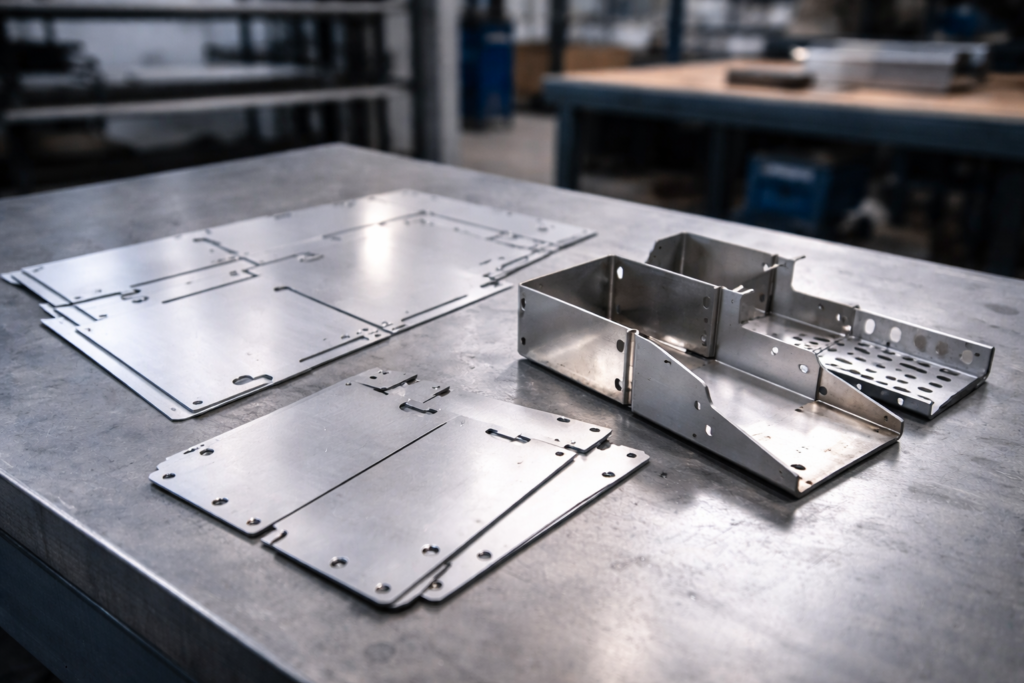

In sheet metal prototyping, for example, a welded enclosure may pass a prototype fit check even though flatness is achieved through manual correction. Once laser cutting, bending, and welding are performed in sequence at volume, residual stress accumulates. Door panels no longer align, mounting holes drift, and rework becomes routine. The prototype was accurate—but it was not honest about distortion risk.

A similar issue appears in a custom metal fabrication prototype produced by CNC machining. A single setup with ideal fixturing may achieve tight positional accuracy. In production, however, fixture wear, tool changeovers, and operator variation introduce shifts that were never tested at the prototype stage.

A Short Manufacturing Scenario Buyers Recognize

Consider a sheet metal cabinet built as a prototype using laser cutting, CNC bending, and manual welding. The prototype fits perfectly after minor hand adjustment. During production, the same design shows door misalignment because the weld sequence was never stabilized and no fixture constrained the long bends during cooling.

Nothing in the prototype was “wrong,” yet the sourcing risk was invisible until bulk orders began. This is why sheet metal prototyping services add the most value when prototypes are intentionally built to reveal distortion, not hide it.

Making Assumptions Visible Without Overengineering

Buyers do not need complex reports to evaluate prototypes. They need clarity around sensitive zones—welded joints, long bends, mating interfaces, and hardware insertion points such as PEM fasteners.

When prototypes expose how these areas behave under realistic constraints, they become a reliable indicator of production readiness rather than a cosmetic approval sample.

Why Highly Refined Prototypes Can Be Misleading

From a procurement standpoint, a flawless prototype can create false confidence. Tight tolerances, smooth finishes, and perfect geometry are comforting, but they may not represent the typical outcome of a stable production process.

Highly refined CNC prototypes often reflect best-case results. They demonstrate what is achievable under controlled conditions, not what is repeatable at scale. If the prototype is finished beyond what production will use, or tolerances are held tighter than production can afford, buyers may approve a sample that sets unrealistic expectations.

This is not an argument against precision. It is an argument for matching prototype intent to production reality. For wholesale programs, the most useful question is: “Which dimensions truly need tight control, and which can be relaxed to improve yield?”

A Practical Reference: Tolerance and Finish Expectations

Even without turning the article into a standard catalog, it helps buyers align expectations around what is typical. Many global manufacturers reference general tolerance standards such as ISO 2768 for non-critical dimensions, while controlling critical features with explicit tolerances.

| Feature type | Prototype emphasis | Production-reality risk |

|---|---|---|

| Critical mating features | Tight control, defined inspection method | Misalignment and assembly rework if capability is not proven |

| Non-critical cosmetic surfaces | “Good enough” finish for evaluation | Over-finishing raises cost without improving function |

| Welded assemblies | Distortion and flatness control | Batch variation if welding sequence and fixturing are not stable |

A prototype that is honest about where variation may appear can be more useful than a cosmetically perfect one.

Material Selection in Prototyping and Its Impact on Cost and Supply Stability

Material choice during prototyping shapes more than mechanical performance. It influences forming behavior, weld response, finishing options, and long-term supply stability. For wholesale buyers, material decisions also affect availability, lead time, and cost volatility.

Substitution is sometimes unavoidable. A supplier may propose a different alloy or thickness due to stock availability. That can be reasonable, but only if the substitution does not change the conclusion you are trying to draw from the prototype.

For example, a prototype made from an easier-to-machine alloy may suggest the design is simple, only for challenges to appear when the intended production material is introduced. Likewise, substituting thinner or softer materials can mask structural weaknesses and reduce the credibility of performance tests.

Linking Material Choice to Procurement Outcomes

For buyers, the key is to connect material selection to production outcomes. From a sourcing perspective, materials influence production outcomes in different ways. Easier-forming materials can lower scrap rates, alloys with stable welding behavior help limit rework, and widely available grades reduce the risk of supply disruption.

When prototyping aligns with these realities, the prototype becomes a reliable forecast of future cost and lead time behavior rather than an isolated success.

How Experienced Buyers and Manufacturers Evaluate Prototypes Differently

Seasoned sourcing teams evaluate prototypes with a different focus than teams who are new to global manufacturing. They care less about whether a single unit looks perfect, and more about whether the supplier can repeat the result under real constraints.

That evaluation often shows up in small but practical questions. How many units were built? Were they built in one run or piecemeal? Were any manual corrections needed to achieve fit? Are the critical features measurable with a defined gauge strategy? Is there a clear plan for First Article Inspection (FAI) and ongoing checks?

These questions are not bureaucracy. They are early indicators of supplier process discipline. A supplier who can discuss repeatability, measurement methods, and variation sources tends to be easier to work with at volume.

The Prototype Evidence Pack That De-Risks Bulk Orders

Top-ranking competitors frequently include strong “how it works” sections and FAQs, but they often skip the buyer’s real need: evidence that a prototype predicts repeatable production. For wholesale sourcing, it helps to standardize the evidence you request with each prototype so you can compare suppliers consistently.

A useful evidence pack does not need to be heavy. It should focus on the few items that correlate with stable production: what was measured, how it was measured, and whether variation was visible even at prototype quantities. This is especially important for welded assemblies and sheet metal prototyping where distortion can shift key features.

| Evidence item | Why it matters to wholesale buyers | What “good” looks like |

|---|---|---|

| Critical-to-quality feature list (CTQ) | Ensures both sides agree on what cannot drift | 5–10 key features with datums and measurement method |

| First Article Inspection (FAI) report (subset is fine) | Creates a baseline for future batches | Measured results with tolerances and units, not “pass/fail” only |

| Process notes for sensitive zones | Makes hidden assumptions visible | Bend sequence, weld sequence, or fixturing notes for key features |

| Variation discussion | Prevents surprise rework later | Supplier explains where variation may occur and how they will control it |

Requesting this level of evidence turns a prototype into a supplier qualification asset rather than a one-time sample.

What “Professional” Looks Like Without Becoming Overly Formal

In B2B sourcing, professionalism is often visible in the basics: clear drawings, consistent revision control, and a shared understanding of critical-to-quality features. It does not require heavy paperwork for every job.

But it does benefit from a few light-touch manufacturing signals—such as identifying key dimensions, providing an inspection report on those dimensions, and explaining how welding distortion or bend variation is controlled. These details help buyers forecast how stable quality will be once orders scale.

Knowing When Prototyping Has Achieved Its Purpose

One of the most overlooked aspects of prototyping is knowing when to move forward. Continued iteration can feel productive, but it can also indicate that the team is chasing perfection rather than reducing the remaining risk.

A prototype has done its job when it resolves the sourcing uncertainty that justified the build. If manufacturability is proven, repeatability is demonstrated, and cost drivers are understood, additional prototypes often provide diminishing returns.

For wholesale buyers, the practical signal is clarity. You should be able to describe what has been validated, what assumptions remain, and what level of risk is acceptable before placing a production order. When that alignment exists, prototyping becomes a bridge to stable supply rather than a delay.

A Quick Buyer Checklist for “Prototype-to-Production” Readiness

Competitor pages that rank well often include simple guidance on next steps—usually framed as process steps. You can keep it non-template by treating readiness as a sourcing decision rather than a workflow.

If you can answer the following in plain language, you are usually ready to transition from prototyping to a production order. First, the supplier has demonstrated repeatability by producing more than one unit without relying on hand fitting. Second, the critical-to-quality features have a defined inspection method and a baseline result. Third, any sensitive areas—long bends, weld zones, mating interfaces—have a practical control plan.

When these elements are in place, sheet metal prototyping services and CNC prototyping stop being “testing” and start being production planning.

FAQ: Metal Prototyping Questions Wholesale Buyers Actually Search

Top-ranking results capture long-tail traffic by answering the questions buyers actually type when evaluating suppliers. These questions are practical, procurement-driven, and focused on risk reduction rather than theory.

How many units should we order for a metal prototype?

One unit can confirm basic fit, but it rarely proves repeatability. For sourcing decisions, ordering three to five pieces makes variation visible without turning the project into a pilot run.

What files are needed for a sheet metal prototype quote?

A 3D model speeds review, but a clear 2D drawing is essential. Highlight critical dimensions, datums, and any areas where flatness, alignment, or cosmetic finish matters. This helps suppliers align sheet metal prototype fabrication with production intent.

What is the typical lead time for prototype sheet metal parts?

Lead time depends on geometry, welding, surface treatment, and hardware insertion. Laser cutting and forming may be fast, while welded assemblies with powder coating take longer. Buyers should focus on whether the supplier explains what drives the schedule.

Is rapid sheet metal suitable for production planning?

Yes, when the prototype uses the same forming approach, bend sequence, and assembly logic as production. Rapid samples that rely on manual correction are useful for fit checks, but less reliable for predicting batch consistency.

What is the difference between sheet metal prototyping and low-volume production?

Prototyping is optimized for learning speed. Low-volume production is optimized for repeatability and cost stability. The transition point is when CTQ features and process controls are clearly defined.

How do we compare two suppliers offering metal prototyping services?

Look beyond appearance. Compare evidence: CTQ definition, inspection method, openness about variation, and how welding, bending, and finishing are controlled. These factors predict long-term performance better than a single polished part.

Conclusion: Using Metal Prototyping to Support Confident Sourcing Decisions

For overseas wholesale buyers, metal prototyping services are not about approving a sample for display. They are about evaluating manufacturing reality before committing to volume. The most effective prototypes reduce uncertainty around repeatability, cost behavior, and delivery stability.

When prototypes are treated as production experiments rather than cosmetic milestones, they provide early insight into supplier capability. This allows buyers to move forward with clearer expectations, fewer surprises, and more stable long-term cooperation.

At YISHANG, we work with sourcing teams who want prototypes that translate into reliable bulk orders. If you would like a second look at your drawings, tolerance strategy, or prototype approach before scaling production, a short technical discussion can often prevent costly revisions later.