Introduction: Why Pipe Sizing Terminology Impacts Your Bottom Line

When wholesale buyers source piping for fluid systems, sheet metal housings, or structural components, precision matters. The terms OD (Outside Diameter), ID (Inside Diameter), and NPS (Nominal Pipe Size) are often assumed to be interchangeable. But misinterpreting any one of them can result in ill-fitting assemblies, wasted production hours, or unnecessary reordering.

If you’re a procurement professional handling bulk or OEM orders, this guide helps clarify dimensional terms and their impact on sourcing decisions. By understanding the nuances between OD, ID, and NPS, you’ll minimize fitment errors, reduce returns, and maintain product integrity across borders and production lines.

This pipe dimension guide for buyers is grounded in the realities of metal component sourcing, RFQ generation, MOQ planning, and global lead time coordination. With increasing complexity in supply chain compatibility, these distinctions matter more than ever.

1. Pipe Size Terminology: Know the Difference Before You Place the Order

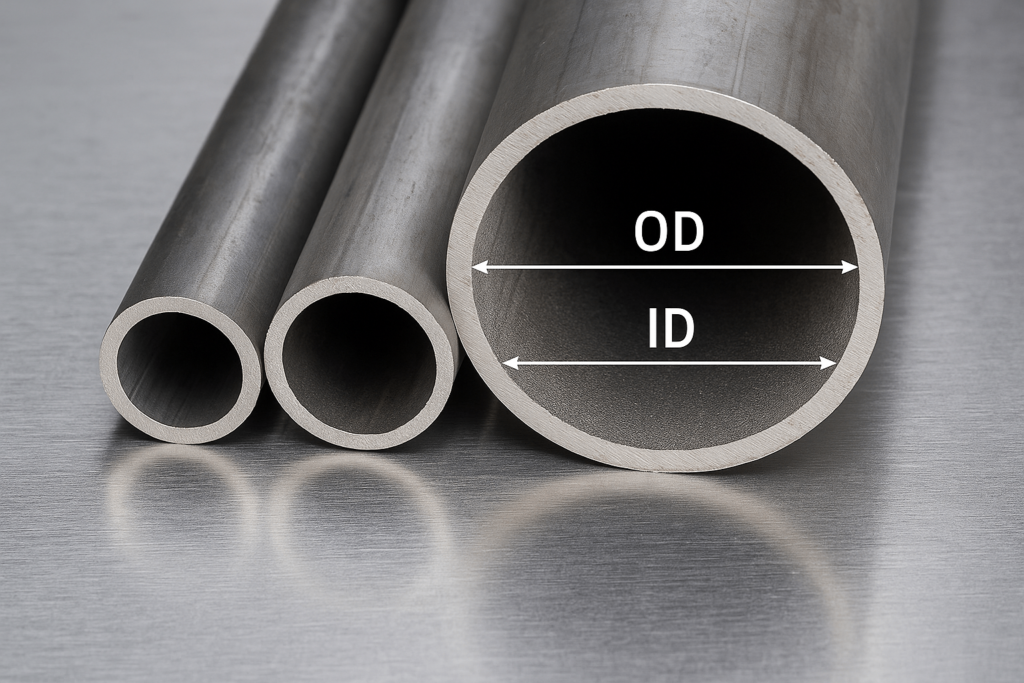

OD (Outside Diameter)

OD is the actual measurement of the outer surface of the pipe. It determines how a pipe fits into brackets, punched holes, or coupling joints. Unlike NPS, OD is measurable with a caliper and non-negotiable during fabrication.

For example, a “1-inch” NPS pipe actually has an OD of 1.315 inches. If your design only accounts for 1.000 inch, your sheet metal parts won’t align. In high-volume manufacturing, these millimeters count.

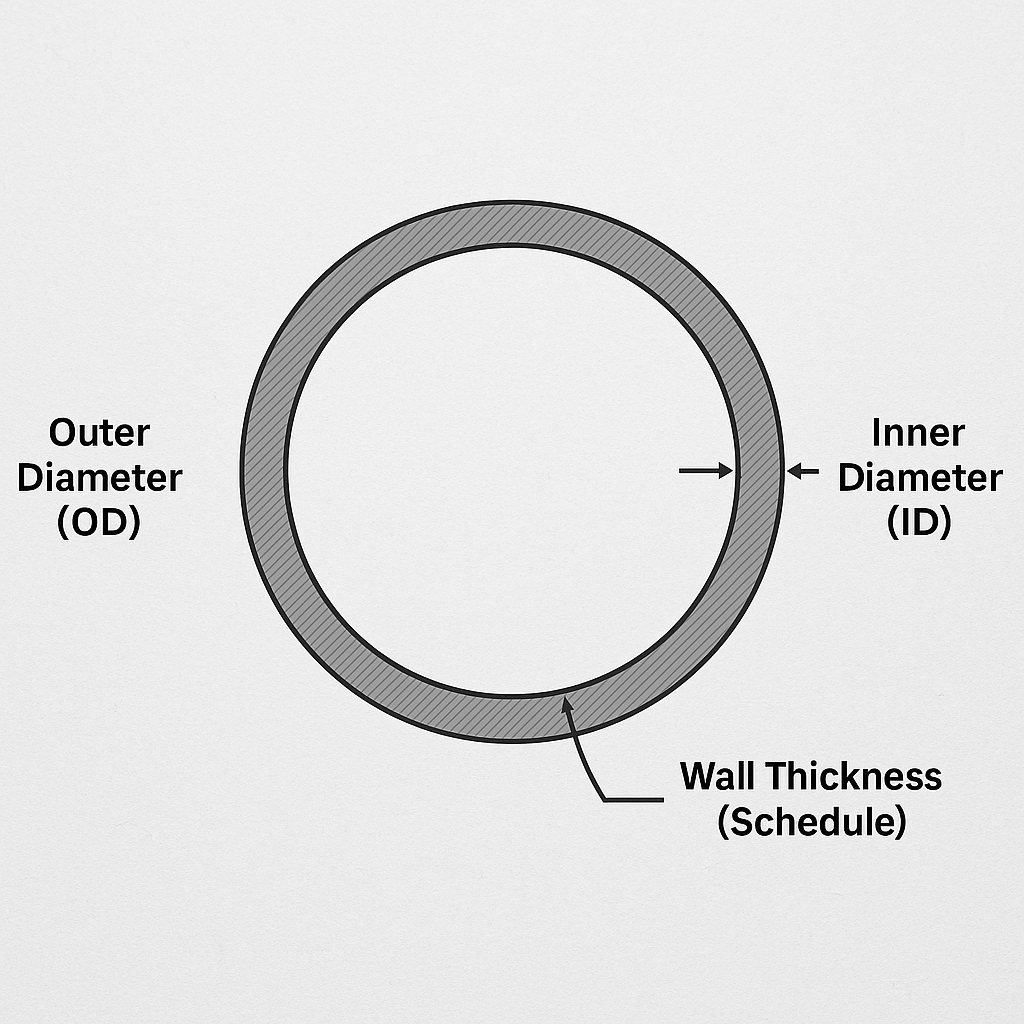

ID (Inside Diameter)

ID refers to the hollow section inside the pipe. It defines fluid flow capacity and pressure drop—especially critical in HVAC or chemical transfer systems. ID varies depending on wall thickness or “schedule.”

A thicker schedule reduces the ID. For instance, a 2” pipe in Schedule 40 has an ID of 2.067 inches, but that shrinks to 1.939 inches in Schedule 80. That difference can restrict flow by over 10%—a real concern in closed-loop circulation or pneumatic systems.

NPS (Nominal Pipe Size)

NPS is a naming standard, not a physical measurement. It provides a reference to OD and schedule without revealing the actual dimensions. For sizes under 14”, NPS and OD rarely match. Above that, they do.

This standard simplifies cataloging, but if used incorrectly, it creates confusion in purchase orders. Always verify whether your drawing refers to NPS, OD, or ID, and clarify with your supplier. If you’re preparing an RFQ, specifying NPS alone without schedule may result in quote delays or sizing misinterpretations.

2. How OD, ID, and Schedule Work Together

In pipe sourcing, OD remains constant for a given NPS, while wall thickness (schedule) adjusts the ID. Understanding this relationship helps buyers select pipes that balance flow performance with structural durability.

Here’s a sample comparison for common sizes:

| NPS | OD (in) | Schedule 40 ID (in) | Schedule 80 ID (in) |

|---|---|---|---|

| 1″ | 1.315 | 1.049 | 0.957 |

| 2″ | 2.375 | 2.067 | 1.939 |

| 4″ | 4.500 | 4.026 | 3.826 |

For wholesale buyers managing inventory across multiple applications, using the wrong ID may require retrofitting or costly replacements. Always cross-reference schedule when quoting or specifying.

Additionally, the pipe material can influence OD tolerance. Seamless stainless steel pipes, for example, have tighter OD control than welded carbon steel variants. In CNC machining or laser cutting, these variances must be pre-validated. Pipe tolerance requirements for OEMs should always be confirmed in technical documentation.

3. What Happens When Sizing Goes Wrong?

In B2B procurement, miscommunication in size terminology is one of the top contributors to product rejection. A seemingly minor error—like specifying a 1-inch pipe without clarifying schedule—can cause flange misalignment or flow failure.

One customer once ordered 500 units of a custom stainless assembly using “1-inch pipe” with no other data. The manufacturer assumed a 1.000″ OD, while the buyer expected a 1.315″ OD NPS pipe. The result: full lot rejection and batch-level rework delays, affecting downstream production and shipping commitments.

Beyond dimensional mismatch, inconsistent sourcing standards can lead to parts that don’t meet pressure specs. For example, Schedule 10 pipes might not withstand industrial fluid pressures, despite sharing the same NPS as thicker Schedule 80 pipes.

Buyers focused on lead time, warranty liability, and service life can’t afford these errors. The takeaway: ask suppliers to confirm OD, ID, and schedule before placing volume orders.

4. Industry Applications: Why This Matters to You

Pipe dimension accuracy is critical across multiple industries:

HVAC Systems: Undersized ID reduces airflow efficiency, increasing energy costs.

Automotive: OD accuracy ensures tubing integrates with pre-designed brackets or weld jigs.

Medical Equipment: Sterile fluid delivery relies on exact ID for dosage calibration.

Petrochemical: Misjudging wall thickness compromises safety and certification.

Wholesale buyers often manage multiple projects across these sectors. Knowing whether the application requires OD-based or ID-based dimensioning avoids costly RMA cycles and logistical headaches.

This is especially relevant when buyers compare tubing vs piping for industrial use. Tubing is typically OD-based, while piping uses NPS and Schedule—making system integration impossible without adapters or spec conversions.

According to industry reports, over 35% of industrial project delays are linked to mismatched part dimensions. That’s not a metric any supplier wants associated with their name.

5. Global Standards: ANSI, ISO, and DIN Explained

For international buyers, it’s crucial to understand that not all “1-inch pipes” are equal.

| System | Reference | Measurement | Region |

| ANSI/ASME | NPS + Schedule | Inch | North America |

| ISO 4200 | OD + Wall Thickness | mm | Global |

| DIN | Nominal Bore + Wall | mm | EU |

If you source from Chinese or U.S. suppliers, your spec might follow ANSI. But if your customer uses ISO 4200 drawings, tolerances and wall thickness may differ.

For instance, a 50mm ISO pipe has a 48.3mm OD—close to a 1.5” NPS ANSI pipe but not interchangeable. Always verify standards in RFQs, especially when integrating cross-market components. Reading NPS charts for fabrication accurately is a fundamental skill in reducing production mismatch.

6. Smart Sourcing Tips for Bulk Buyers and Distributors

Confirm the System Early

When placing bulk orders, clarify whether the drawing follows tubing (OD-based) or piping (NPS-based) logic. Many procurement teams default to “1 inch” thinking it means OD. It rarely does.

Request Tolerances

In sheet metal and CNC applications, OD tolerances matter. A ±0.5mm deviation can cause misalignment with mating components. Don’t assume—specify.

Consider Schedule & Application

For structural components, Schedule 40 may be sufficient. But for high-pressure lines or submerged environments, opt for Schedule 80 or higher. Confirm that the MOQ structure accommodates your actual batch volumes.

Minimize Inventory Waste

Choosing the wrong spec not only leads to return costs—it also burns MOQ inventory and increases lead time unpredictability. Be sure before buying.

Insist on Documentation

A reliable supplier like YISHANG provides ASME-compliant drawings and can meet ISO 9001 or RoHS standards. Always ask for these documents upfront to ensure supply chain compatibility and risk-free batch production.

7. Frequently Asked Questions

Is pipe size measured by OD or ID?

Pipe size under NPS refers to OD, but the ID varies with schedule. Tubing is typically measured by OD.

What is the OD of a 1-inch pipe?

NPS 1” pipe has an OD of 1.315 inches, not 1.000 inch. This is standard per ASME B36.10.

Can I interchange ISO and ANSI sizes?

Not directly. Even slight differences in OD or wall thickness make them incompatible without adapters.

How do I prevent sourcing errors?

Always include NPS, Schedule, OD, and ID. Confirm standards, ask for drawings, and clarify tolerances.

What’s the difference between tubing and piping?

Tubing is dimensioned by OD and wall thickness; piping follows NPS and Schedule. They’re not cross-compatible.

Conclusion: Precision Sizing Protects Margins

In pipe sourcing, the difference between 1.000″ and 1.315″ isn’t just math—it’s money. It’s product uptime, client confidence, and brand reputation.

For wholesale buyers, engineers, and sourcing teams, mastering OD, ID, and NPS ensures accuracy from RFQ to final assembly. Know your specs, confirm your schedule, and choose partners who understand what’s at stake.

Need accurate metal components that match your specs? Contact YISHANG to get your quote today.