In the world of global procurement and industrial supply, the term “rust-proof” is often used, but it fails to capture the complexity of real-world material degradation. For a procurement manager or a product developer, a component that fails prematurely due to corrosion is more than an inconvenience; it’s a threat to brand reputation, a trigger for costly warranty claims, and a disruption to the supply chain. The true objective is not a vague promise of being “rust-proof,” but the engineered certainty of lifetime corrosion control.

This guide moves beyond a simple list of coatings and rust prevention methods. It presents a strategic framework for specifying the precise protection system for any given application. By understanding how to diagnose the specific challenge—balancing the environmental threats with the project’s performance and lifecycle cost goals—you can shift from hoping a product lasts to engineering it to endure. This is the critical difference between reactive maintenance and proactive design, and it is the foundation of creating metal assets that deliver predictable, long-term value.

Part 1: The Diagnostic Framework — Define the Corrosion Environment Before You Choose a Coating

The most significant and costly error in corrosion control is specifying a solution before fully diagnosing the problem. A coating that performs flawlessly in a dry, controlled warehouse may fail catastrophically in a coastal marine environment, leading to premature product failure. Therefore, the first step in any professional corrosion prevention plan is a rigorous risk assessment. At YISHANG, our process begins by mapping every project onto a diagnostic matrix defined by two critical axes: the severity of the environmental threat and the primary performance goal of the finished product.

🔗 Reference: ISO 9223 Corrosion Classification Standard

Axis 1: The Environmental Threat Level

The service environment is the primary driver of corrosion speed and severity. According to international standards like ISO 9223, we can classify these environments into distinct threat levels, each with its own set of chemical and physical aggressors. Understanding these environmental factors is paramount for accurate specification.

- C1 (Controlled): This category includes indoor, climate-controlled spaces where the primary threat is ambient humidity. While seemingly benign, fluctuations in temperature can cause condensation, providing the necessary electrolyte for corrosion to begin on unprotected surfaces. This is a key consideration for sensitive components inside a climate-controlled enclosure.

- C2 (Temperate): This represents standard outdoor exposure in most inland urban or rural areas. The primary threats are direct contact with rain, the formation of dew due to temperature cycles, and general atmospheric humidity. The combined effect of temperature and humidity is a major driver of atmospheric corrosion in these settings, making a robust barrier essential for any outdoor electrical enclosure.

- C3 (Aggressive): This level is characteristic of coastal and marine environments, or inland regions where de-icing salts are heavily used in winter. The defining threat is a high concentration of airborne chlorides from salt spray. Chloride ions are highly aggressive; they increase the conductivity of moisture, accelerate electrochemical reactions, and can break down the protective passive layers on metals like stainless steel and aluminum.

- C4 (Industrial/Chemical): This environment is defined by the presence of atmospheric pollutants, which are common in heavy industrial zones. Gases like sulfur dioxide and nitrogen oxides dissolve in atmospheric moisture to form acid rain. This acidic electrolyte is highly corrosive and can degrade not only the base metal but also many standard protective coatings.

Axis 2: The Primary Performance Goal

Beyond the environment, the intended function and desired outcome of the project dictate the ideal protection strategy. The required coating performance must be clearly defined to ensure the final product meets all functional, aesthetic, and financial requirements.

- Aesthetics & Finish: For architectural elements or any application where visual appeal is paramount, the choice of coating is driven by color, gloss, texture, and long-term appearance retention.

- Maximum Durability / Zero-Maintenance: For infrastructure exposed to corrosive environments or inaccessible installations, coatings must last decades without failure.

- High-Wear & Impact Resistance: For exposed enclosures or frames, the system must endure impacts, abrasion, and surface wear.

- Budget-Conscious Balance: Projects with tight budgets must find the optimal trade-off between initial cost and long-term durability.

Part 2: The Corrosion Control Matrix — Matching Protective Coatings to Environments

With the challenge clearly defined, the Corrosion Control Matrix identifies the appropriate protection systems. This tool aligns environmental threat (C1-C4) with performance goals, providing a data-driven starting point. It supports procurement teams in evaluating material and coating tradeoffs for diverse product categories, such as sheet metal frames, outdoor signage structures, or marine-grade enclosures.

| Aesthetics & Finish | Maximum Durability / Zero-Maintenance | High-Wear & Impact Resistance | Balancing Initial Investment with Service Life | |

|---|---|---|---|---|

| C1: Controlled | Powder Coating, Quality Paint | Anodizing (Aluminum), Passivated Stainless Steel | Powder Coating, Hard Anodizing (Type III) | Quality Paint, Oil/Wax Film |

| C2: Temperate | Powder Coating, Duplex System (Color) | Hot-Dip Galvanizing, Duplex System | Hot-Dip Galvanizing, Powder Coating | Hot-Dip Galvanizing, Quality Paint System |

| C3: Aggressive | Duplex System (Required) | Duplex System (Required) | Duplex System, Hard Anodizing (Marine Aluminum) | Hot-Dip Galvanizing (with maintenance plan) |

| C4: Industrial | Specialty Duplex System (Chemical-resistant topcoat) | Specialty Duplex System | Epoxy or Polyurethane over Galvanizing | Specialty Epoxy/Polyurethane Coatings |

Part 3: Advanced Protection Tactics — Duplex Coatings and Stainless Steel Passivation

Pro Tactic 1: Duplex Systems — Best Coating Strategy for Harsh Environments

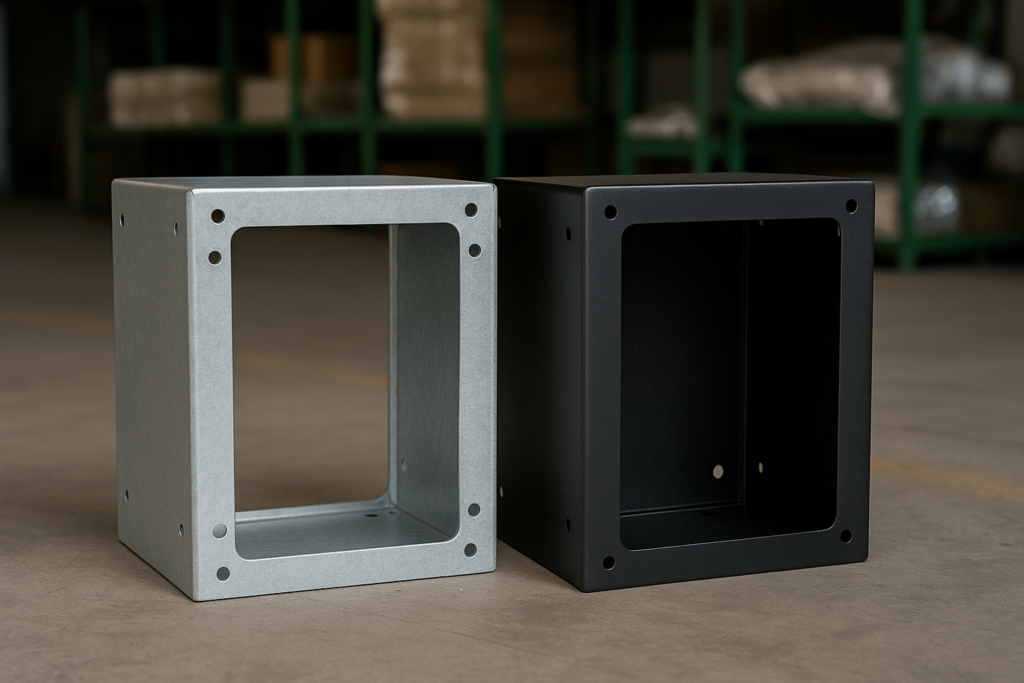

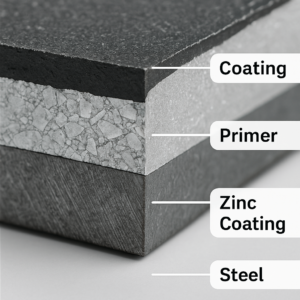

In high-threat environments (C3 and C4), standalone protection systems often fail. The duplex system—a powder or paint topcoat over hot-dip galvanizing—offers superior protection via a synergistic effect. This combination extends service life by 1.5 to 2.3 times beyond the combined lifespan of the separate layers.

The outer coating shields the galvanized layer from environmental exposure, delaying zinc consumption. When the outer layer is breached, the zinc offers sacrificial protection. Unlike untreated steel, the zinc’s corrosion products do not expand, preventing coating delamination. This makes duplex systems particularly effective for large-volume metal frames and equipment housings exposed to harsh outdoor conditions.

📎 Ensure preparation meets ASTM D7803 standard to ensure proper adhesion between zinc and topcoat.

Pro Tactic 2: Stainless Steel Passivation — Essential Final Step for Rust Prevention

Stainless steel is not inherently rust-proof. Fabrication introduces contamination—free iron from tools or welds—that disrupts its passive layer. Without remediation, rust will develop despite material selection.

Passivation, per ASTM A380, uses nitric or citric acid to dissolve contaminants, enabling reformation of a chromium-rich oxide film. This layer restores corrosion resistance and ensures compliance with hygiene or longevity requirements. It is not optional; it is a final quality-control step.

Part 4: Real-World Applications — How Industry Uses These Protection Strategies

Scenario 1: Duplex Coatings for Urban Architectural Steelwork

For exposed steel beams in a C4 urban setting with a 50-year service goal, aesthetics and durability are critical. A duplex system—galvanizing plus UV-stable polyurethane powder coating—is specified. This protects against atmospheric pollutants while meeting color and finish demands.

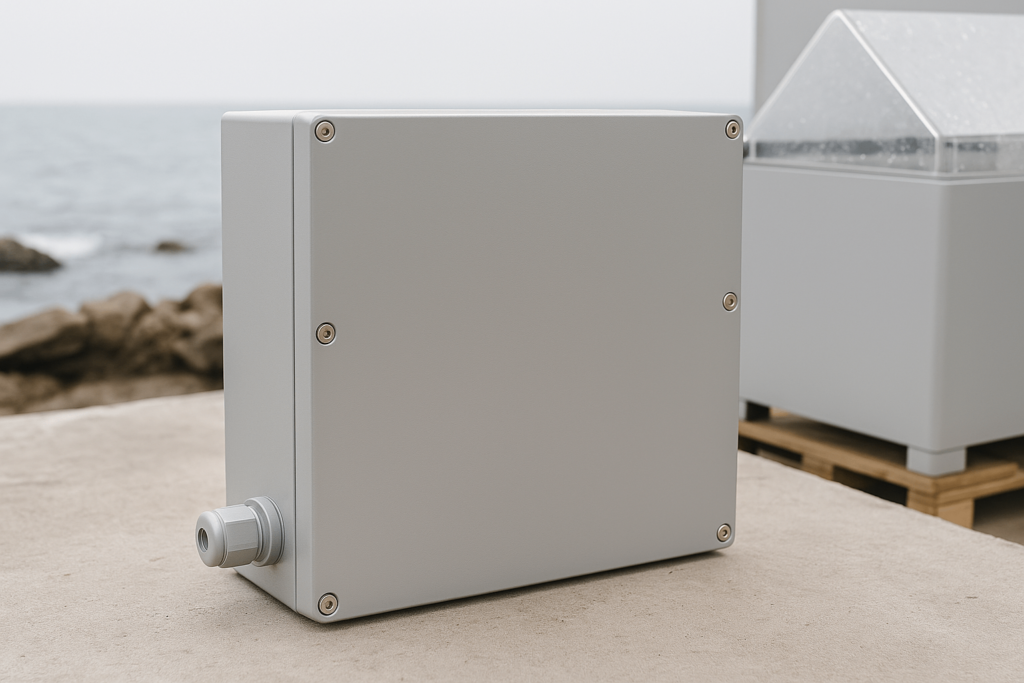

Scenario 2: Hard Anodizing for Marine Aluminum Enclosures

Aluminum enclosures for marine electronics (C3) demand salt spray resistance and dimensional stability. Hardcoat anodizing (Type III) delivers a dense, wear- and corrosion-resistant oxide layer. Sealing the anodized surface ensures impermeability and surface integrity.

Scenario 3: Passivated Stainless Steel in Food-Grade Manufacturing

304/316 stainless steel tables in acidic, moisture-heavy environments (C4) require post-fabrication passivation. This ensures a stable chromium oxide layer and compliance with hygienic standards.

Part 5: Salvaging Corroded Metal — A Rust Recovery Process for Industrial Assets

Step 1: Rust Removal — Wet Blasting or Chemical Cleaning

Wet blasting uses a water-abrasive slurry to safely remove surface rust while minimizing dust. For enclosed parts or precise tolerances, chemical baths may be more effective.

Step 2: Neutralization — Prevent Flash Rust Post-Cleaning

After chemical cleaning, apply an alkaline rinse (e.g., baking soda solution) to neutralize acid residues before recoating.

Step 3: Re-Coating — Lock in Protection Before Exposure

Immediately apply rust-inhibiting primers or full protective coating systems. Choosing the right protective coating for outdoor reapplication determines long-term performance.

Frequently Asked Questions

Q1: What is the best way to prevent rust on stainless steel parts?

A1: Stainless steel should undergo passivation after fabrication to restore its protective oxide layer, especially in food-grade and industrial applications.

Q2: Is hot-dip galvanizing enough for coastal environments?

A2: In most C3/C4 environments, hot-dip galvanizing alone is insufficient. A duplex system combining galvanizing with a powder coating top layer is recommended.

Q3: What’s the difference between rust-proof and corrosion-resistant metals?

A3: “Rust-proof” is often a marketing term. True corrosion resistance depends on material selection, surface treatment, and environmental conditions.

Conclusion: Longevity Isn’t an Accident — It’s Engineered.

Effective corrosion control isn’t about generic rust-proofing—it’s about engineering. Diagnosis, selection, and execution drive success. This is how procurement professionals move from reactive fixes to proactive asset design.

Longevity stems from strategy, standards, and expert fabrication—not luck. At YISHANG, we help clients turn corrosion challenges into long-term value.

Suggested Internal Links: