Why Procurement Teams Are Re-Evaluating Metal Manufacturing

For B2B buyers sourcing small-to-mid volume metal parts, the pain points are familiar: long lead times, expensive tooling, and rigid setups that resist design updates. Traditional methods like CNC and casting aren’t optimized for fast iteration or niche product launches.

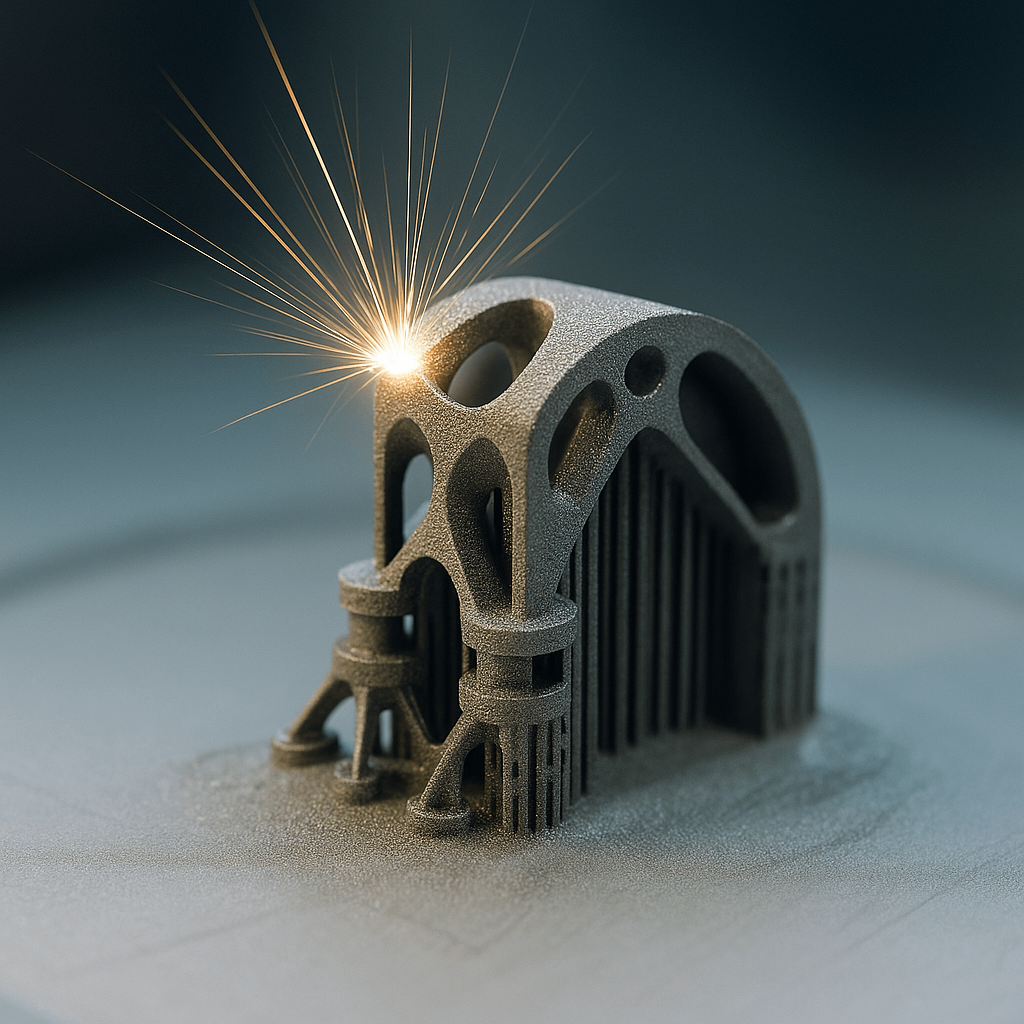

Selective Laser Melting (SLM) eliminates these bottlenecks. It enables direct-from-CAD production with no molds, faster turnaround, and fewer SKUs. For sourcing managers, that means lower MOQs, cleaner BOMs, and better control of revision cycles.

What Is Selective Laser Melting, Really?

SLM is a form of powder bed fusion that fully melts powdered metals inside an inert gas chamber. Common materials include aluminum, stainless steel, and titanium—all of which have melting thresholds that SLM machines routinely exceed. For example, the 6061 aluminum melting point is around 582°C–652°C, while the melting point of stainless steel can reach up to 1530°C.

SLM is especially valuable for low-to-mid volume production where tooling costs are prohibitive or lead times are critical.

What Materials Can Be Used—and Why It Matters

SLM is compatible with a range of industrial-grade metals. Buyers must consider both physical performance and supply chain impact.

| Material | Key Features | Applications |

|---|---|---|

| 6061 Aluminum | Lightweight, conductive, machinable | Housings, enclosures, heat sinks |

| Ti6Al4V | Biocompatible, strong, corrosion-resistant | Implants, aerospace connectors |

| 316L Stainless Steel | Durable, corrosion-resistant | Tooling, marine, medical |

| Inconel 718 | Heat-resistant, fatigue-resistant | Turbine parts, energy sector |

| Brass / Bronze | Conductive, decorative (what temperature does brass melt: ~930°C) | Fixtures, heritage parts |

Buyers evaluating suppliers should understand how each material’s properties and melting points—like bronze melting point (~950°C), or cast iron melting temperature (~1200°C)—impact build stability, cooling, and post-processing steps.

Powder morphology (shape, size distribution) also affects flowability and final density. Always request powder specs when quoting custom jobs.

Design for SLM: What Buyers Need to Know Before Quoting

Buyers should treat SLM as a performance tool—not a 1:1 swap with traditional manufacturing. Additive manufacturing requires its own logic.

SLM thrives with geometry consolidation, lattice infill, and custom internal channels. But unsupported overhangs (>45°), poor heat paths, and narrow escape channels can trigger print failures or post-processing challenges.

Before quoting:

Ask for build orientation suggestions

Confirm support removal feasibility

Require thermal simulation output

These steps prevent costly trial-and-error and reduce build failure rates. It also gives procurement teams more control over cost transparency.

SLM Applications in B2B Supply Chains

SLM already supports real-world B2B production. These are not theoretical pilots—they’re live RFQs:

Aerospace: Engineered brackets, custom nozzle components, and lightweight fuel systems. Jet nozzles are printed for environments operating near carbon steel melting point (~1425°C).

Medical: Hip implants with lattice cores improve osseointegration. SLM allows for customization without extra tooling.

Energy and Industrial: Turbine parts made of Inconel 718 withstand extreme temperatures. Housings with internal cooling outperform cast alternatives.

EV and Robotics: Thermal manifolds and heat sinks in aluminum 6061 variants reduce weight and improve thermal response.

In each case, SLM answers not only technical demands—but also commercial goals: MOQ reduction, part consolidation, and global lead-time agility.

Common Buyer Concerns—and What to Ask Suppliers

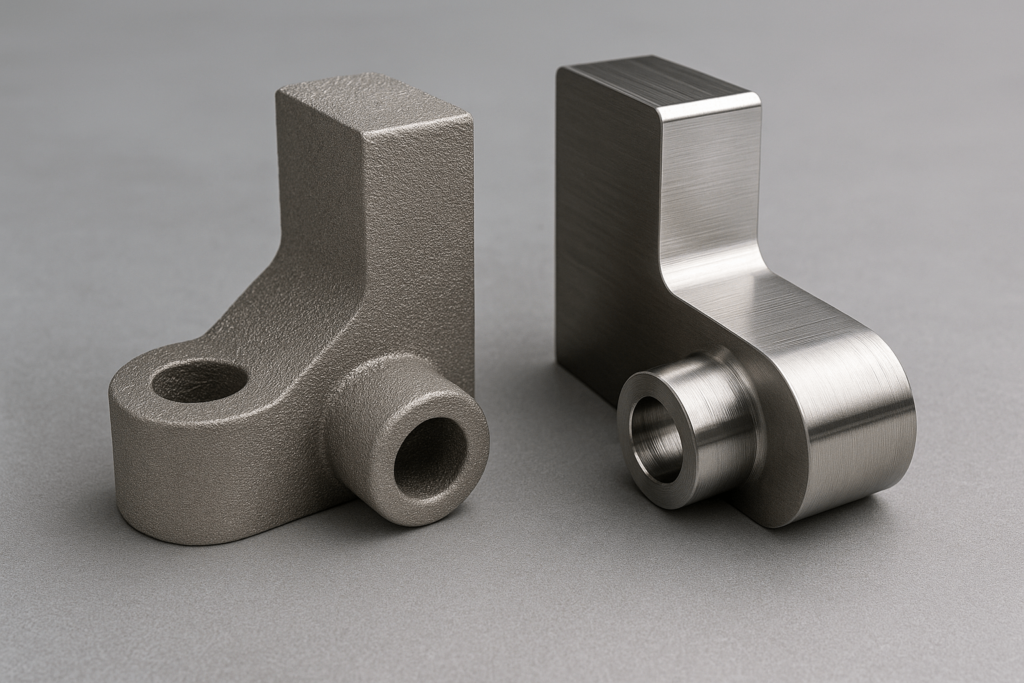

Surface Quality: Ra values on raw SLM parts typically range from 8–20μm. CNC finishing is often required for tight fits.

Support Considerations: Internal supports can increase cost. Confirm support removal feasibility during DfAM review.

Geometry Constraints: Not all CAD models are printable. Ask for DfAM review before quoting.

Sample questions to ask:

Can you provide past build reliability data?

What’s the expected recoater clearance for this part?

Will powder evacuation be an issue in the current design?

These ensure both part quality and quote accuracy.

Hybrid Manufacturing: Why Many Buyers Prefer It

Combining SLM with CNC or casting reduces cost and increases design freedom. Buyers often order:

Additively printed cores + CNC-machined surfaces

Complex internal paths via SLM + outer casings via die casting

Low-volume SLM runs + cast tooling for scale-up

This hybrid strategy provides flexibility while minimizing risk. It’s especially useful for prototyping functional samples that later migrate to other methods.

What’s Evolving in SLM That Impacts Buyers

SLM technology is evolving fast. Buyers can now benefit from:

Multi-laser machines: Reduce per-part cost by 40% in many builds

In-process inspection: Cameras catch melt pool deviations in real time

Material expansion: Including copper, tool steels, and lead-based alloys (what temperature does lead melt: ~327°C)

Quoting AI: Software that simulates builds before approval, reducing failed jobs

These upgrades lower cost variability and increase quote reliability.

FAQ: Quick Facts for Industrial Buyers

What quantities are ideal for SLM?

Typically 1–500 pieces, depending on part size. Higher if build plate nesting is efficient.

What’s the melting point of stainless steel?

Between 1375°C and 1530°C. All SLM systems used by YISHANG are capable of handling this.

Is SLM sustainable?

It reduces waste, but energy use varies. Powder recycling is possible but limited by particle aging.

Can I use SLM parts without CNC finishing?

Yes—for non-mating surfaces. But critical areas should be machined or polished.

Does YISHANG offer turnkey service?

Yes. From DfAM optimization to post-processing, inspection, and packaging—we handle the full lifecycle.

Where can I find a reliable supplier for SLM metal parts?

If you’re looking for a reliable supplier for SLM metal parts, YISHANG offers global support with professional DfAM consultation and fast RFQ response for small to medium batch production.

Final Insight for Procurement Managers

SLM is not just an innovation—it’s a procurement advantage. It lowers MOQ, eliminates tooling costs, and enables faster product iteration without sacrificing quality.

YISHANG supports full-scope RFQs for SLM, including integrated CNC and sheet metal solutions. If you’re considering how to build complex metal parts with better economics, we’re ready to advise and quote.