Introduction: Why the Surface Finish is the “Invisible Architect”

In industrial manufacturing and architectural projects, choosing the right stainless steel finish is more than an aesthetic consideration—it’s a long-term performance decision with direct implications for durability, maintenance, and client satisfaction.

For bulk purchasers, OEM product developers, and supply chain managers, misjudging a surface finish can mean premature corrosion, elevated maintenance cycles, and project delays.

This guide offers a practical, experience-backed framework tailored to international B2B decision-makers. It outlines how different finishes impact functional longevity, cost structure, and brand value over time.

Part 1: The Finish Spectrum – A Comprehensive Look at Your Options

Understanding the full palette of stainless steel surface treatments is essential for informed procurement. The finish affects corrosion resistance, formability, reflectivity, and even hygiene compliance. This spectrum ranges from utilitarian raw mill conditions to high-performance, engineered treatments.

1.1 The Industrial Cornerstone: Mill Finishes (The Starting Point)

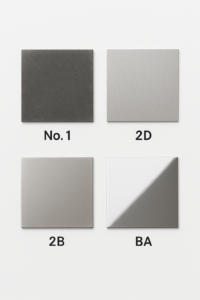

Every stainless steel product starts with a “mill finish,” the default surface state after rolling and heat treatment—standardized under ASTM A480.

A No. 1 Finish, hot-rolled and annealed, is rough and non-reflective, suited for heavy-duty industrial applications.

The No. 2D Finish, cold-rolled and pickled, yields a uniform, matte surface ideal for deep drawing and forming.

The widely used No. 2B Finish is smoother and moderately reflective. It’s the default in global supply chains and often serves as the base for further finishing due to its balance of availability, price, and polish potential.

A Bright Annealed (BA) Finish is produced by annealing in a controlled atmosphere to prevent oxidation, creating a clean, reflective surface with good formability and corrosion resistance.

1.2 The Craftsman’s Touch: Mechanical Finishes (The Art of Balancing Aesthetics and Function)

Mechanical finishes physically alter the steel surface using abrasives or pressure to create refined textures for practical or aesthetic purposes.

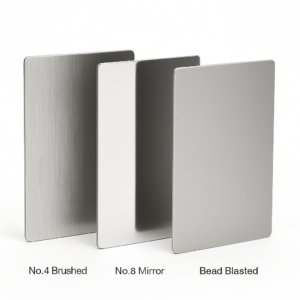

The No. 4 “Brushed” Finish, a staple in appliances and architecture, has a directional grain that diffuses light and masks minor surface wear—making it a practical choice for public-facing or high-touch components.

(Image 1: A close-up of a No. 4 Brushed stainless steel panel, showing the linear grain structure.)

The No. 8 “Mirror” Finish is mechanically polished to a flawless reflection. It’s valued in clean rooms, decorative panels, and anywhere maximum corrosion resistance or hygiene is essential.

Bead Blasting produces a uniform, matte, non-directional finish by bombarding the surface with glass or ceramic beads—effective at reducing glare and hiding surface inconsistencies.

Patterned and Embossed Finishes, formed through pressure rolling, introduce repeatable textures that enhance stiffness and visual complexity without increasing material thickness.

1.3 The Peak of Performance: Advanced Surface Treatments (Engineered for Demanding Environments)

Some applications demand more than visual appeal or light abrasion resistance—they require engineered surfaces.

Electropolishing is an electrochemical process that removes a microscopic layer of metal, producing a surface with minimal roughness. The result is improved corrosion resistance, enhanced cleanability, and reduced microbial adhesion.

PVD (Physical Vapor Deposition) Coating applies ultra-hard ceramic films in a vacuum environment. PVD enhances wear resistance and adds stable color options without compromising stainless integrity. It’s also VOC-free, aligning with modern green manufacturing expectations, as further explored in Part 5.3.

At YISHANG, these advanced finishing solutions are integrated into OEM workflows across healthcare, electronics, and vending equipment sectors, enabling functionally optimized components at scale.

Part 2: The Decision Matrix – A Head-to-Head Comparison of Key Options

After identifying available finishes, buyers must weigh trade-offs between appearance, durability, cost, and application context.

2.1 Brushed vs. Mirror (#4 vs. #8): The Debate Between Practicality and Perfection

The No. 4 Brushed Finish is well-suited for moderate exposure environments and conceals minor wear, making it ideal for public or high-traffic zones.

The No. 8 Mirror Finish, while visually striking and offering superior corrosion resistance, is prone to showing handling marks and requires controlled cleaning procedures.

When appearance, corrosion performance, and long-term maintenance intersect, the mirror finish is superior—but may demand stricter handling and a higher upfront investment.

This comparison supports a broader point: finish selection should be environment- and lifecycle-driven, not just aesthetic. More guidance follows in Part 3.1.

2.2 PVD Coating vs. Traditional Finishes: Is the Upgrade Worth It?

For luxury hardware, exterior fixtures, or hygiene-sensitive zones, PVD provides unique benefits:

- Increased surface hardness and scratch resistance;

- Expanded design flexibility through color finishes;

- Long-term UV stability and no chemical leaching.

While the cost per unit is higher, the upgrade is often cost-neutral when factoring in reduced warranty claims and lower replacement cycles.

Quick Reference: Which Finish is Right for You?

| Feature | 2B Mill Finish | #4 Brushed | #8 Mirror | Bead Blasted | PVD Coated |

|---|---|---|---|---|---|

| Appearance | Cloudy Mirror | Soft, Lined Satin | True Mirror | Uniform Matte | Colored/Metallic |

| Hides Fingerprints | Fair | Excellent | Poor | Good | Good |

| Hides Scratches | Poor | Good | Poor | Excellent | Excellent |

| Corrosion Resistance | Good | Good | Excellent | Good | Excellent |

| Initial Cost | Low | Medium | High | Medium | Very High |

| Best For… | Industrial Parts | Appliances, Architecture | Decorative Accents | High-Touch Surfaces | Luxury Fixtures |

Part 3: The Strategist’s Playbook – Specifying for Application and Long-Term Value

Choosing a finish is a decision that links engineering logic with commercial foresight. This section equips industrial buyers and project specifiers with best practices to align surface selection with environmental conditions, durability expectations, and lifecycle budgets.

3.1 The Environmental Matching Rule: The “Grade + Finish” Synergy

The true performance of stainless steel depends not only on its alloy grade but also on the compatibility between finish and operating environment.

In standard conditions, Grade 304 stainless often suffices. Yet in coastal, chemical, or industrial zones, Grade 316 is critical due to its molybdenum content, which enhances pitting resistance.

More importantly, surface smoothness determines corrosion resistance. Smoother finishes harbor fewer contaminants and are easier to sanitize.

A 316 + Mirror or Electropolished Finish is optimal in marine or cleanroom applications. In contrast, a 316 + Brushed Finish can trap chlorides in its directional grain, accelerating corrosion. This is a common and costly mismatch that buyers should avoid by always evaluating environmental severity before specifying.

If you’re evaluating options for corrosion-resistant metal surface treatment in high-humidity or chloride-heavy conditions, pairing the right grade with a hygienic finish is crucial.

3.2 Beyond the Price Tag: The Economics of Life Cycle Costing (LCC)

Upfront price is not the full picture. Life Cycle Costing (LCC) evaluates a material’s true economic impact over time:

LCC = Initial Cost + Operational/Maintenance Costs – Residual Value

For stainless steel, high recyclability and low maintenance often outweigh a higher starting cost. For example, polished 316 may cost more initially, but if it extends component life by 10 years and halves replacement frequency, the overall project budget benefits.

YISHANG’s clients in the vending and medical sectors routinely choose upgraded finishes for this reason: they reduce service downtime, replacement scheduling, and warranty exposure.

Whether you’re sourcing for architectural panels or precision enclosures, understanding stainless steel finish comparison by lifecycle cost can prevent overspending down the line.

Part 4: The Often Overlooked Frontier – Maintenance and Long-Term Surface Integrity

Surface finish directly influences daily usability, cleaning protocols, and long-term appearance. Smart selection upfront can reduce maintenance labor, chemical usage, and equipment shutdowns.

4.1 Maintenance Profiles by Finish Type: Cost, Frequency, and Risk

| Finish Type | Cleaning Frequency | Maintenance Cost | Risk of Visible Wear |

|---|---|---|---|

| No. 2B | Low | Minimal | Moderate |

| No. 4 Brushed | Medium | Moderate | Low |

| No. 8 Mirror | High | High | High |

| Electropolished | Very Low | Very Low | Very Low |

| PVD Coated | Low | Moderate | Very Low |

Brushed finishes mask wear but require periodic cleaning along the grain. Mirror finishes require delicate handling to maintain clarity, making them better suited for controlled-access environments.

Electropolishing creates a smooth, passive layer ideal for medical and food facilities due to its low surface tension and easy cleanability. PVD finishes resist scratches and fading, reducing both cosmetic defects and rework costs.

4.2 Real-World Case: When Finish Fails, Function Follows

A European display system integrator used brushed 316 stainless for outdoor vending enclosures. Within 18 months, exposure to salt air caused tea-staining and discoloration along grain lines.

After switching to a mirror electropolished finish, maintenance dropped by 50% and finish failures were eliminated over the next 5 years. This illustrates how surface choices can directly influence operational success or failure.

Part 5: Innovation Frontiers – Trends Reshaping Stainless Steel Finishes

Beyond traditional applications, stainless steel finishing is now at the forefront of manufacturing innovation. Buyers that recognize these trends can align with evolving regulatory standards and design expectations.

5.1 Advanced Robotics: The Rise of Automated Surface Finishing

Robotic polishing arms and CNC brushing systems are transforming finish consistency. They reduce error, improve safety, and allow tighter tolerances for high-volume production.

YISHANG integrates robotic deburring and intelligent surface control systems, especially for retail, medical, and enclosure components where uniform grain and gloss are required at scale.

5.2 Green Chemistry in Surface Treatment: Beyond Aesthetics

Eco-conscious finishing eliminates toxic acids and VOCs. Electrolytic coloring, aqueous polishing compounds, and closed-loop filtration systems reduce environmental impact while enhancing workplace safety.

This trend is aligned with international environmental standards, enabling exporters to meet EU REACH and RoHS compliance more easily.

5.3 PVD’s Expanding Role in Sustainable and Aesthetic Finishing

Revisited from Part 1.3, PVD coatings not only extend surface durability but also provide colorfast, chemically stable finishes without hazardous runoff.

Applications range from architectural hardware to sanitary ware, combining decorative appeal with technical resilience. For buyers balancing aesthetics and compliance, PVD is fast becoming the finish of choice.

Frequently Asked Questions (FAQ)

Q1: Can I use a mirror finish outdoors?

Yes—if matched with Grade 316 and regular cleaning, mirror finishes resist corrosion in coastal and polluted zones. Electropolishing further enhances this.

Q2: Is PVD worth the extra cost?

In high-touch, prestige, or harsh-use scenarios, yes. PVD improves durability, aesthetics, and lowers cleaning frequency.

Q3: What’s the most corrosion-resistant finish available?

Electropolished 316 stainless is top-tier for corrosion and hygiene.

Q4: What if I want a custom color?

Use PVD. It enables gold, black, bronze, blue, and other durable color options that won’t flake like paint.

Q5: Which finishes are easiest to clean?

Smooth, non-porous finishes like PVD, mirror, and electropolished are best for sanitation and wipe-down frequency.

Conclusion: One Decision, Years of Impact

Choosing a stainless steel finish is not just a specification—it’s a strategic investment in performance and brand reliability.

The right finish minimizes total cost of ownership, ensures compliance, and supports cleaner design aesthetics across product categories.

From heavy-duty vending housings to surgical brackets and retail fixtures, stainless finish decisions echo through every use cycle. Whether you’re looking for a marine-grade stainless steel finish, a low-maintenance stainless steel solution for the food processing industry, or a custom stainless steel finishing supplier in China, selecting the optimal finish will influence performance for years to come.

With this guide, B2B buyers can now evaluate finish options not only by appearance, but by measurable value across a component’s lifespan.

Need help choosing the right stainless steel finish? Contact our engineering team for tailored advice or a free quote.

Specify with precision. Deliver with confidence.