A Lightweight Solution Worth Engineering

Titanium die casting is increasingly appealing to industrial buyers seeking high-strength, corrosion-resistant, and lightweight metal parts. Yet its extreme melting point, reactivity, and low thermal conductivity make it a uniquely difficult material to process compared to aluminum or zinc.

This article breaks down what procurement and engineering teams need to know—covering castable alloys, cost implications, scalability, and what separates viable titanium casting suppliers from the rest.

Why Titanium Isn't Just Another Casting Metal

Titanium stands out for its high strength-to-weight ratio. But its casting behavior is anything but straightforward.

Its melting point exceeds 1660°C, far higher than aluminum or zinc. This challenges conventional die materials and causes oxidation issues like alpha-case.

Standard automated die casting setups can’t handle this. Titanium reacts with oxygen, nitrogen, and carbon during melting, leading to surface defects and mold erosion.

Moreover, titanium’s low thermal conductivity causes uneven solidification. That leads to porosity and tolerance variation—issues that are unacceptable in precision components.

These limitations make titanium die casting a task that demands not just heat but also tight environmental control, tooling strategy, and technical oversight.

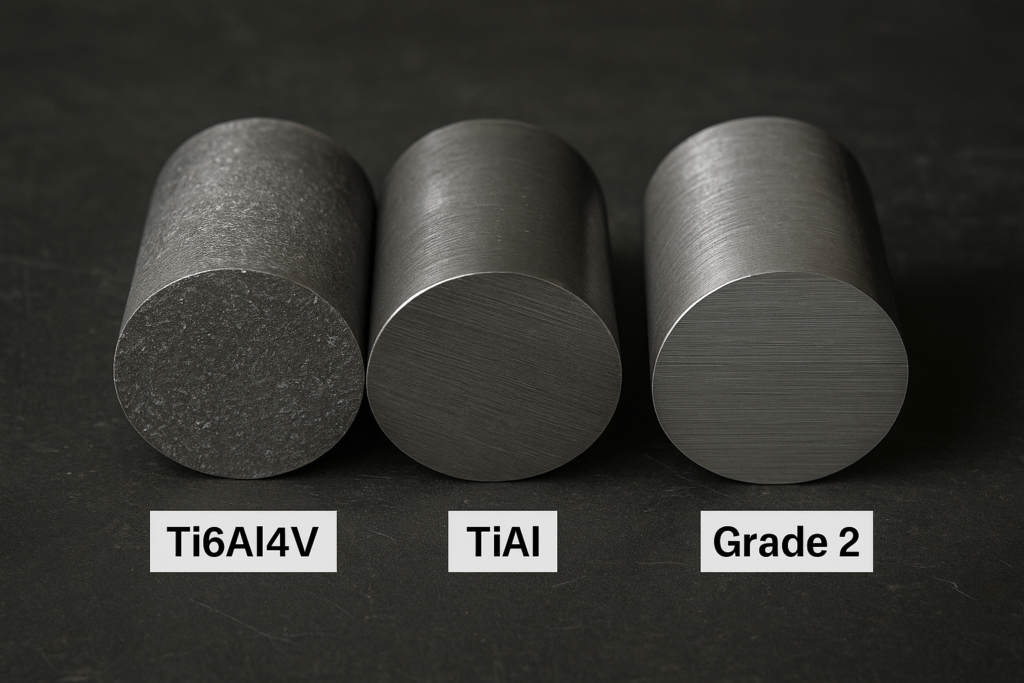

The Right Titanium Alloys Make All the Difference

Not every titanium grade suits die casting. Some are unworkable in molds due to poor flow or high reactivity.

Grades like Ti Grade 2 or 3 are strong but hard to cast. Titanium aluminide (TiAl), by contrast, performs well in high-pressure or advance die casting settings due to its flowability and resistance to oxidation.

Ti6Al4V, a common aerospace alloy, can be adapted to pressure or gravity casting with the right mold coatings, though it usually originates in investment or precision casting.

Titanium Alloy Cheat Sheet

| Alloy | Best Use | Castability | Comments |

|---|---|---|---|

| Grade 2 | Medical implants | Poor | High purity, low cast flow |

| Ti6Al4V | Aerospace, defense | Moderate | May need mold coatings |

| TiAl | EV, turbines | High | Best flow, moderate strength |

Ensure compliance with ASTM B367 or equivalent standards to meet mechanical performance expectations.

Casting Titanium Requires Specialized Processes

Unlike alloy die casting for aluminum or zinc, titanium cannot be handled in typical hot or cold chamber setups.

Due to titanium’s chemical reactivity, specialized environments are required. This includes inert gas chambers (argon), ceramic mold coatings, and vacuum casting infrastructure.

Proven practices include:

Ceramic-coated dies to limit reaction

Mold preheating above 700°C

Flow simulation tools for fill prediction

Precision pressure control

When combined with high-pressure automated die casting lines, these practices ensure contamination is minimized and thermal cycling remains tightly controlled within ±5°C. The result is higher dimensional accuracy and improved repeatability—two factors essential in large-scale titanium component programs.

Where Titanium Die Casting Excels in Supply Chains

Die cast titanium components deliver exceptional strength, corrosion resistance, and lightweight performance across critical applications.

Aerospace & Defense

Cast titanium brackets and mounts reduce airframe weight by 30–40%, improving fuel efficiency and vibration resistance. Common use includes drone armatures and missile components.

Medical Devices

Use cases include surgical tools and orthopedic cages due to titanium’s biocompatibility. Casting allows near-net-shape fabrication, lowering the need for post-processing and reducing contamination risks.

EVs, Robotics & Storage Systems

Die cast titanium offers excellent heat stability and EMI shielding, ideal for components such as battery modules, robotic actuators, and storage frames. Custom titanium die casting enables consolidation of complex features.

Harsh Industrial Applications

Valves and housings in corrosive environments last significantly longer when die cast using titanium alloys. Marine hardware, oil & gas parts, and lab enclosures see extended service life.

These applications highlight how titanium casting isn’t universal, but is ideal where structural and chemical durability align with production volumes.

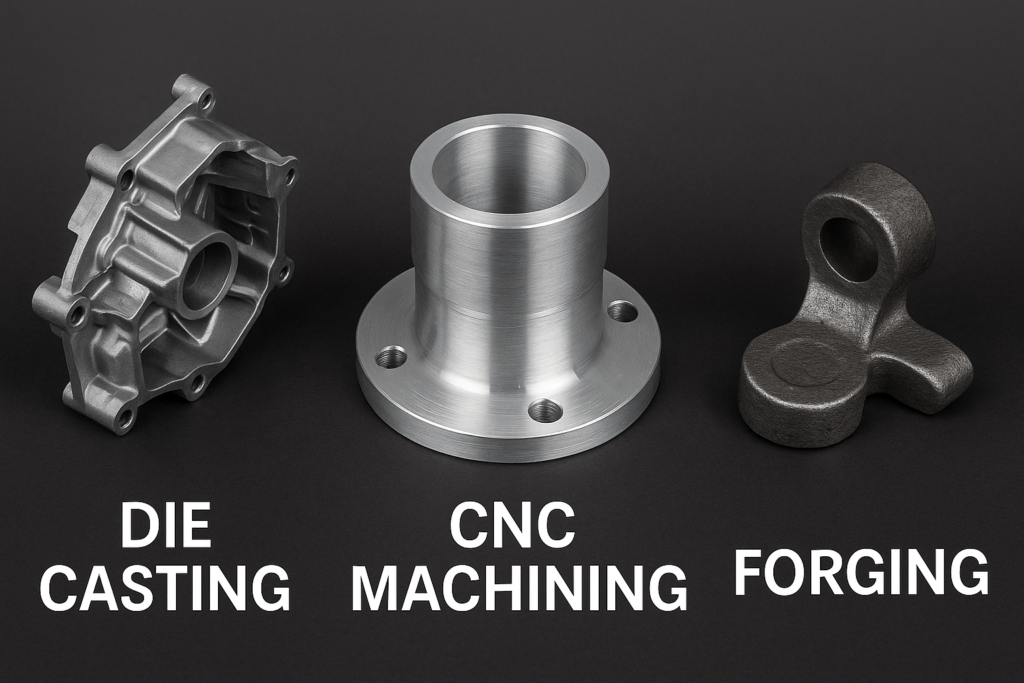

How Titanium Die Casting Compares to Other Methods

Sourcing managers often compare titanium die casting with CNC machining or forging. Each method has trade-offs based on volume, complexity, and performance targets.

| Metric | Die Casting | CNC Machining | Forging |

| Material Yield | High | Low | Medium |

| Shape Flexibility | High | Medium | Low |

| Batch Suitability | 500+ units | Low | High |

| Unit Cost | Moderate | High | Moderate |

| Ideal Use | Net-shape parts | Prototyping | High-force loads |

For titanium, low volume titanium die casting starts to outperform CNC when batch sizes exceed 300–500 units annually, especially when geometries are complex.

Cost Considerations and Long-Term ROI

Titanium die casting carries higher upfront costs—particularly for tooling and vacuum equipment—but can yield cost advantages over time. While raw titanium and specialized alloys like TiAl are expensive, these inputs are offset by downstream savings and performance efficiency. Yet the reduced post-machining and longer part lifespans result in a lower total cost of ownership.

For instance, a precision titanium component for EV battery frames can reduce machining time by over 80%, especially if designed with casting tolerances in mind.

Once tooling is amortized across 3–5 batches, unit pricing often falls below CNC equivalents, while reducing scrap rates and improving production repeatability.

Scalability and Production Readiness

Titanium die casting has matured into a viable mass production option for specific parts. It no longer belongs solely to R&D or aerospace prototyping.

Buyers should evaluate supplier capacity, especially in:

High-pressure titanium casting experience

Vacuum chamber control and maintenance

Mold coating material quality (Y2O3, Al2O3, etc.)

Annual throughput and past defect ratios

A qualified titanium casting supplier should be able to share tolerances, case studies, and certifications openly.

Advance die casting systems now handle batch volumes of 5,000+ units with 2–3% scrap rates. If your parts require lightweight strength and moderate complexity, titanium is worth evaluating.

Sourcing Insights: What Buyers Should Know

Procurement professionals should focus on clarity at the RFQ stage. Here are key points:

MOQ: Most titanium die casting suppliers set MOQs between 300–500 units depending on part size and mold complexity.

Lead Time: Allow 8–10 weeks for first runs. Repeat orders typically ship in 4–6 weeks.

Precision: ±0.1 mm tolerances are feasible with optimized mold design.

Finishing: Light CNC post-machining or chemical passivation is standard—minimal rework needed.

Documentation: Request ASTM B367 certification, material batch traceability, and mold life estimates.

These details help align sourcing expectations with actual factory capabilities.

FAQ: Practical Answers for Procurement and Engineering Teams

Q: Is titanium die casting more expensive than aluminum?

Yes initially, but the lifecycle cost is often lower due to part longevity and reduced machining.

Q: What is die casting and how does it differ from investment casting?

Die casting uses reusable steel molds and high-pressure filling; investment casting uses ceramic shells and wax patterns. Die casting suits medium-high volumes.

Q: Can pure titanium be diecast?

Not efficiently. Most commercial projects use titanium alloy casting—especially TiAl and Ti6Al4V.

Q: Can I get sample titanium castings before mass production?

Yes, after tooling is prepared. Some suppliers also offer CNC-simulated samples for early evaluation.

Q: What parts are commonly made with titanium die casting?

Battery holders, robotic joints, medical tools, aerospace clips, marine valves, and enclosures.

Ready When the Application Demands It

Titanium die casting isn’t the best fit for every part. But for mid-volume, high-strength components with tight tolerances—such as those in aerospace, EV systems, or medical-grade assemblies—it consistently outperforms forging and CNC alternatives in both cost and performance.

The real ROI comes when choosing a capable partner. A bulk titanium parts manufacturer experienced in low-cost titanium casting solutions and titanium die castings for medical OEMs can help you bridge the gap between prototype and full-scale production.

Have a drawing or spec to review? Let’s talk feasibility and lead times.