Introduction

For international procurement teams sourcing electrical enclosures, the National Electrical Code (NEC) isn’t just a technical guideline—it’s a critical benchmark. Whether you’re supplying OEM systems, data centers, commercial facilities, or industrial plants in North America, your junction boxes must comply with NEC standards.

Non-compliance doesn’t just risk project delays. It results in failed inspections, customs issues, and, in many cases, total shipment rejection. This guide translates NEC requirements into practical insight for bulk buyers, highlighting how YISHANG supports customers in building NEC-compliant, high-performance junction box solutions from design to delivery.

Understanding NEC: What It Means for Wholesale and OEM Procurement

The NEC—developed by the National Fire Protection Association (NFPA)—sets the safety standard for electrical installations across the U.S. and many export markets. Though local codes may slightly vary, NEC remains the dominant framework. For procurement professionals, this translates into a need for suppliers who can fabricate products not just to spec—but to code.

Key NEC articles related to junction boxes include 314.16 (box fill), 314.28 (space requirements), 314.29 (accessibility), and 250.148 (grounding). Understanding these isn’t a matter of engineering curiosity—it’s a qualification for project success. The ability to source NEC-compliant junction boxes is now a differentiator in competitive bids, especially for infrastructure and energy applications.

YISHANG supports buyers with pre-tested designs, NEMA-certified enclosures, and full-volume data. Our team collaborates closely with electrical engineers to ensure that everything from conductor spacing to access clearances aligns with applicable NEC articles.

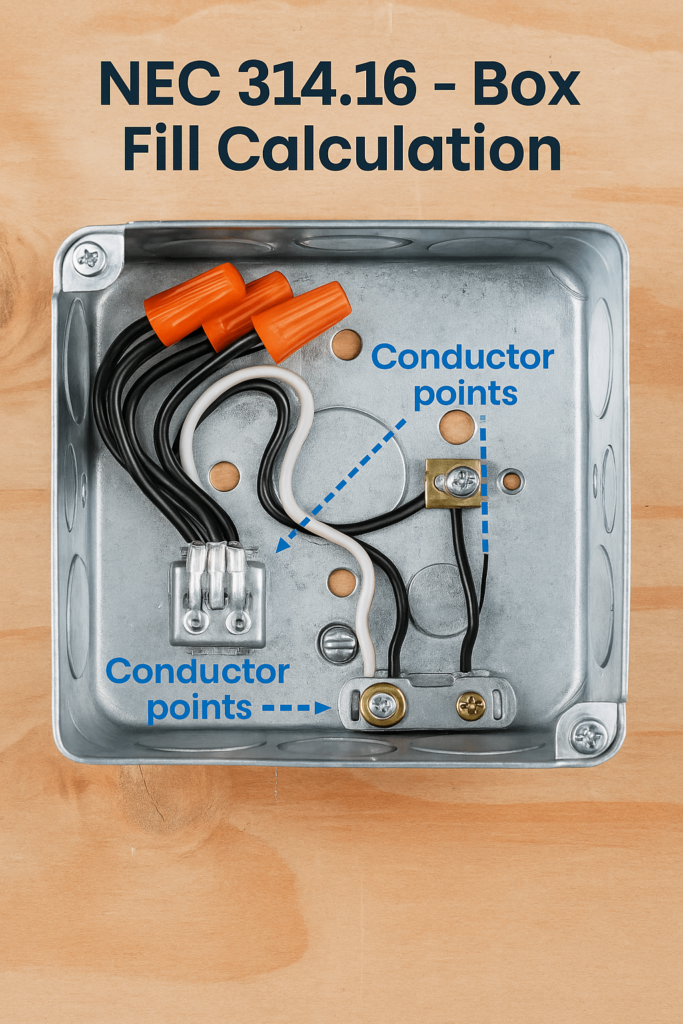

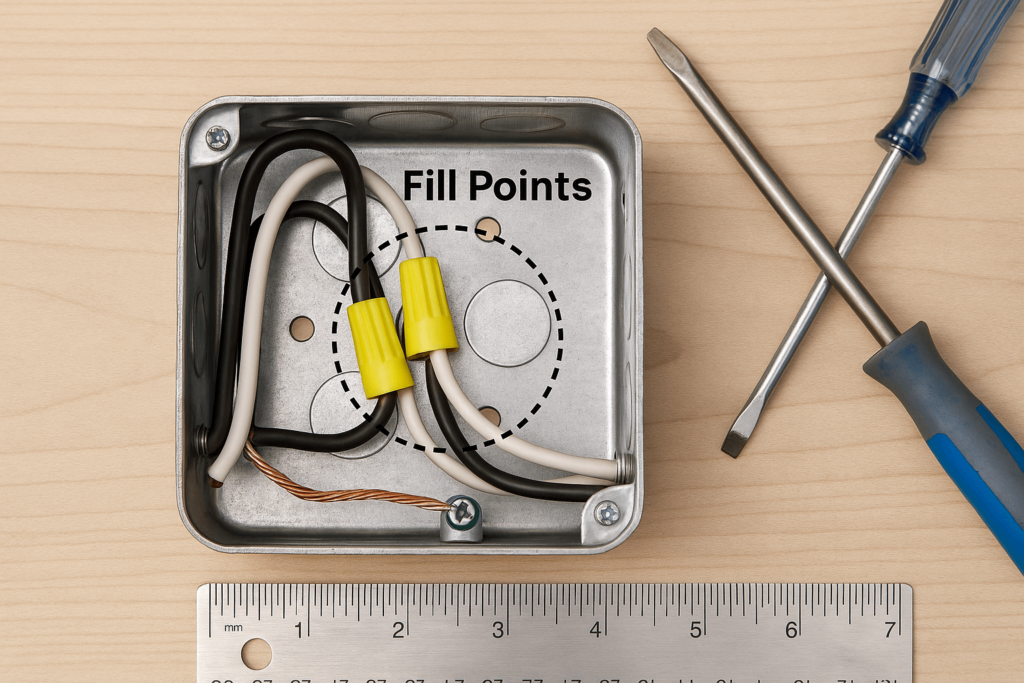

Box Fill and Volume Calculations: NEC 314.16 Explained

At high volumes, incorrect box sizing can scale into costly failures. NEC 314.16 governs box fill—the calculation that determines how many wires and components a box can legally and safely contain. Each element occupies volume:

| Component Type | Allowance (cu. in.) |

|---|---|

| #14 conductor | 2.00 |

| #12 conductor | 2.25 |

| #10 conductor | 2.50 |

| Grounding conductors | Counted once total |

| Internal clamps | 1x |

| Device yokes | 2x per yoke |

For example, a junction box containing 6 #12 conductors, 1 ground, and 1 duplex outlet requires a minimum of 20.25 cubic inches. Underestimating this requirement in production or quoting leads to violations, heat buildup, and failed safety checks.

YISHANG uses digital modeling and box fill calculators integrated into our prototyping phase. Our engineers validate every box design using NEC-specified conductor volumes, ensuring all drawings sent to fabrication are fully compliant.

Box Dimensions and Conduit Entry: NEC 314.28 Requirements

NEC 314.28 targets physical spacing requirements for pull and junction boxes. These standards ensure proper bending radii and ease of wire pulls, especially in systems with large gauge conductors or complex conduit layouts. Straight pulls demand box lengths 8x the trade diameter of the largest conduit; angle pulls require calculated spacing based on entry side and conductor count.

A miscalculated enclosure not only risks cable damage but makes field installation difficult—wasting time and manpower. For procurement professionals, this means verifying that quoted enclosures accommodate both internal components and external conduit entry without field modification.

YISHANG offers full CAD support to ensure optimal conduit positioning. We adjust flange depths, entry angles, and spacing during the quotation phase, reducing field retrofitting and increasing project efficiency.

Material, Environmental Ratings, and Export Considerations

Junction boxes used in outdoor or harsh environments must meet NEC 314.15, which requires weatherproof or corrosion-resistant designs. Buyers targeting industries like oil & gas, telecom, marine, or agriculture must ensure the boxes they import meet NEMA 3R, 4, or 4X—or IP65/IP66 for European equivalents.

Material selection matters. Steel offers rigidity and grounding reliability, while aluminum provides lightweight corrosion resistance. For washdown zones or coastal regions, stainless steel is the preferred option. YISHANG manufactures all three, offering UL-listed options with grounding studs, lock-seamed edges, and tamper-resistant closures.

To support global buyers, we supply serialized technical datasheets with each shipment—clearly documenting NEMA rating, box fill capacity, mounting layout, and grounding compliance.

Accessibility and Maintenance: NEC 314.29 in Practice

NEC mandates that all junction boxes remain accessible post-installation. A common compliance failure? Boxes buried in insulation, ceilings, or behind permanent panels. While such placements might save visual space, they fail NEC 314.29 and make maintenance risky.

YISHANG incorporates this requirement directly into product design by offering enclosures with modular or front-panel access. Our in-house teams can also integrate laser-marked access labels or mounting tabs to ensure that field technicians and inspectors easily locate junction points.

This attention to detail helps procurement teams avoid surprise rework or inspection flags, especially on export-driven infrastructure projects.

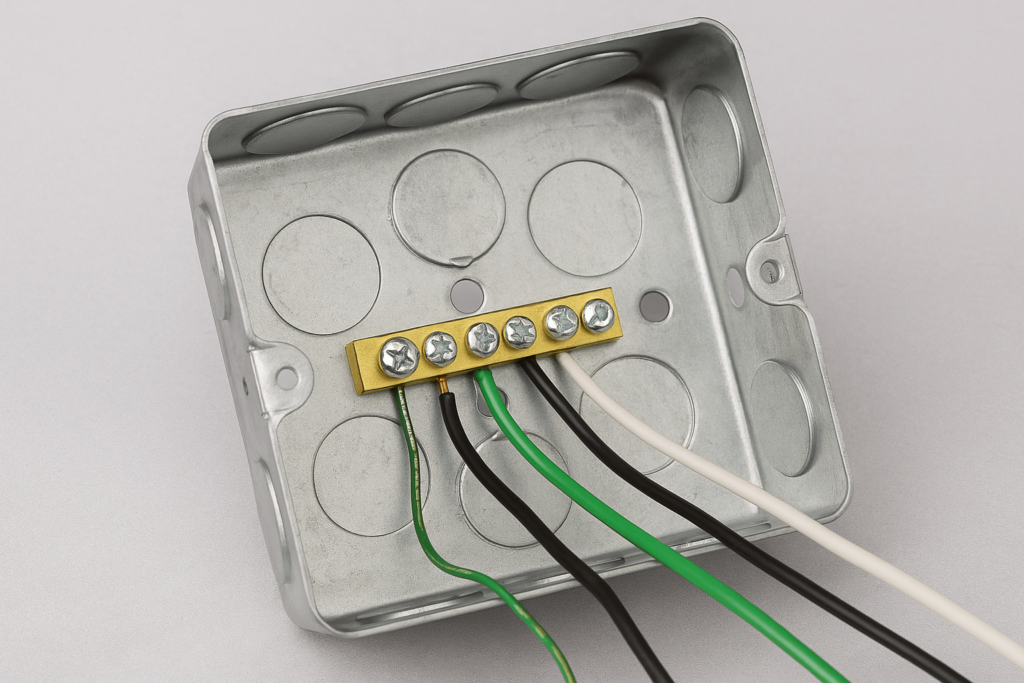

Grounding and Bonding Requirements: Inside NEC 250.148

For metallic boxes, NEC 250.148 demands grounding that is independent of the device yoke. Every grounding conductor must be spliced together and bonded to the box, often through a dedicated ground screw or terminal.

Neglecting this is one of the top causes of inspection failure in commercial installations. For bulk buyers, it’s essential that suppliers provide boxes that allow simple, secure ground connection—no field modification required.

All YISHANG enclosures can be equipped with pre-installed grounding terminals, UL-approved clamps, or internal bus bars as needed. This ensures that large-volume deployments in commercial and industrial environments stay compliant across locations.

Case Study: How One OEM Achieved 100% First-Pass NEC Approval

An OEM partner in Canada sourced 2,000 custom junction boxes from YISHANG for a national data center rollout. The project required IP66/NEMA 4X-rated enclosures with pre-mounted terminal blocks, conductor spacing compliant with NEC 314.16, and side-entry configurations that met NEC 314.28 standards.

By collaborating early in the design process, we delivered batch-tested enclosures that passed Canadian inspection on the first attempt. The customer reported a 15% time saving on installation due to simplified grounding layouts and optimized access points.

This case reflects the real impact of sourcing from a supplier that understands both NEC and OEM execution challenges.

Integrating Compliance into Procurement Workflows

NEC-compliant sourcing doesn’t happen at the tail end of a project. It starts with documentation, verification, and transparent communication from the very first RFQ. Bulk buyers need more than a product—they need a fabrication partner.

YISHANG helps procurement teams by offering 3D models, compliance datasheets, ISO 9001 production logs, and prototyping for evaluation. We reduce risk by showing upfront how each box design satisfies NEC volume, grounding, and access rules—so your spec submittals and approval processes run smoother.

We also provide flexible minimum order quantities (MOQs), batch inspection support, and traceable part numbers for accountability across global supply chains.

Summary and Procurement Takeaway

Meeting NEC requirements isn’t about checking boxes—it’s about delivering value, safety, and long-term operational certainty. Procurement teams play a strategic role in choosing the right manufacturing partners to meet these standards.

YISHANG simplifies this process by embedding code compliance into every phase of production. From customized box fill design and NEMA enclosure ratings to grounding integrations and export documentation, we serve as a complete fabrication solution for OEM and wholesale customers.

References

– National Fire Protection Association (NFPA) – https://www.nfpa.org

– NEC 2023 Edition Code Index – https://www.nfpa.org/70

– UL 50E Enclosure Rating Guide – https://www.ul.com

Frequently Asked Questions (FAQ)

Q: Do junction boxes have to follow NEC code in the USA?

A: Yes, NEC governs all aspects of junction box installation—including size, fill, material, and grounding.

Q: What is NEC 314.16?

A: NEC 314.16 defines the required box volume based on wire count, device yokes, clamps, and grounding.